Magnesium-alloy surface pre-treatment

A processing method and technology of magnesium alloy, applied in the direction of metal processing equipment, abrasives, manufacturing tools, etc., can solve problems such as harsh working environment, human body and environmental hazards, uneven surface of rough embryos, etc., to improve the working environment and improve adhesion , quality and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

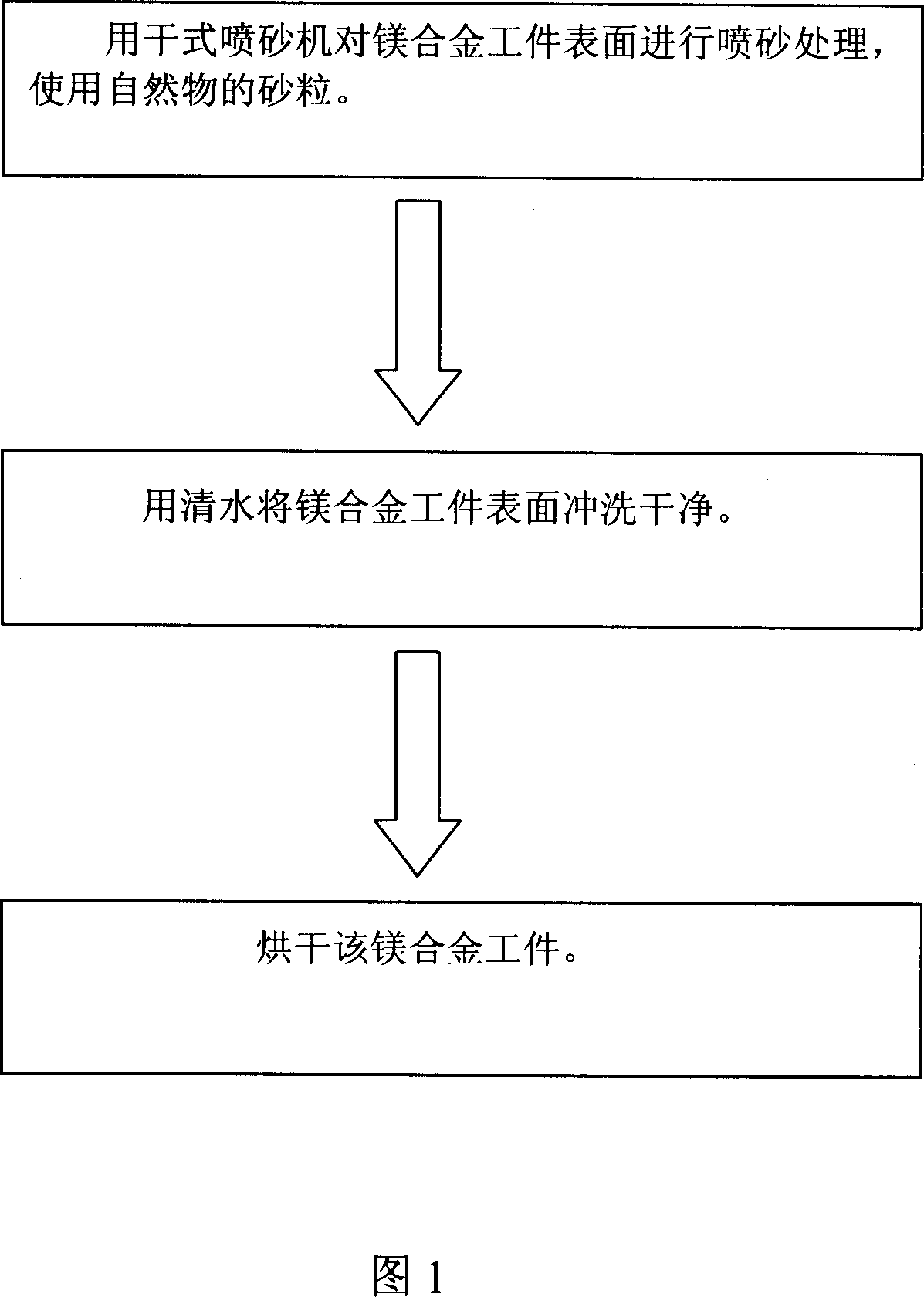

Method used

Image

Examples

no. 1 example

[0025] The above is the first embodiment of the present invention. In fact, the magnesium alloy material treated by the method of the present invention can carry out various subsequent processes on the surface of the magnesium alloy material, such as various coatings or electroplating, electrocoating, Spray paint, bake paint, etc., not just vacuum sputtering.

[0026] In addition, in the second step, a high-pressure air gun can also be used to blow off the surface of the magnesium alloy material, and then the magnesium alloy material can directly enter the vacuum sputtering step.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com