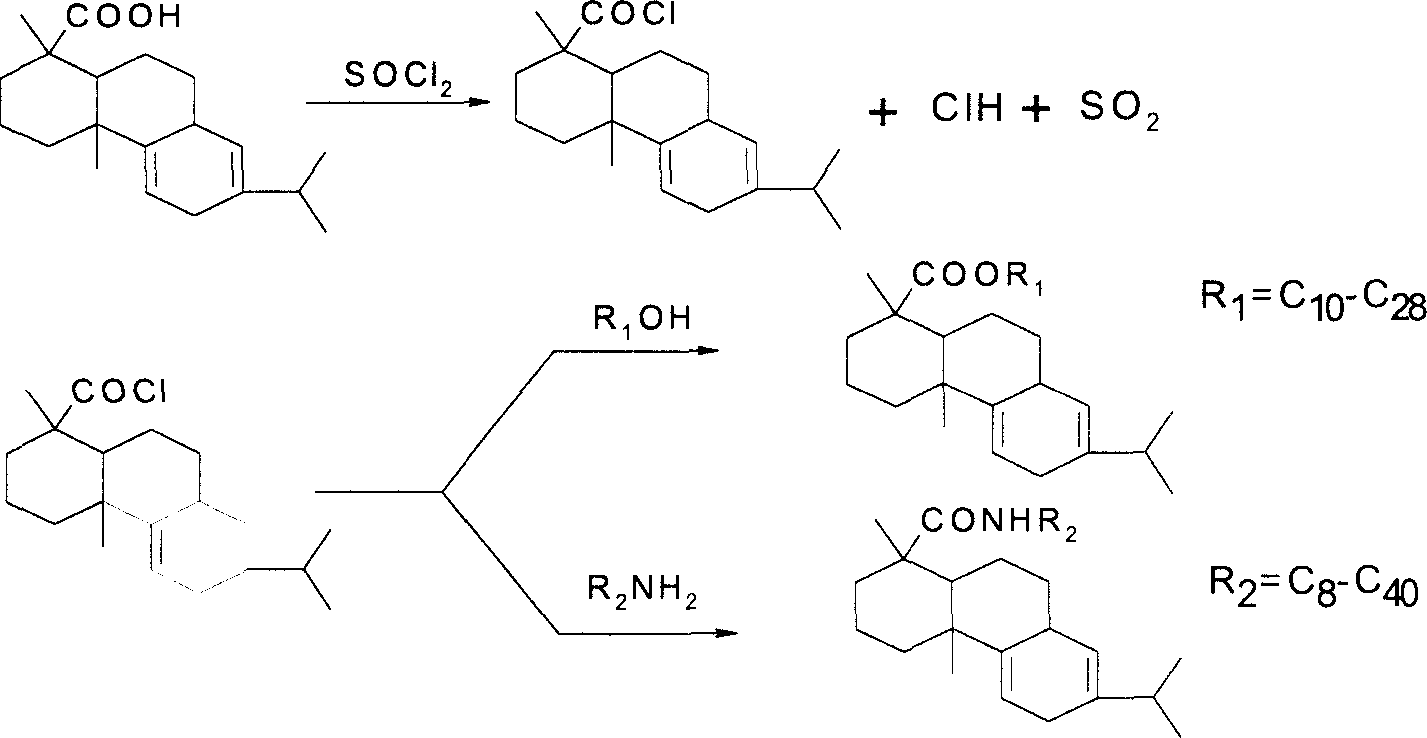

Diesel wax-crystal nucleation dispersant and its synthesis

A technology of dispersant and diesel wax, which is applied in the field of rosin acid higher alcohol ester or amide and its synthesis, to achieve the effects of enhanced pour point depressant effect, broad application prospect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 0.04 mol of abietic acid, add it to a 250ml flask, add 20ml of toluene, start the stirring device, and completely dissolve the abietic acid. Take 0.03 mol of thionyl chloride, add it to the dropping funnel, add it dropwise to the flask, control the dropping rate of thionyl chloride, and complete the addition in about 45 minutes. At the same time, use a gas absorption device with a calcium chloride drying tube (drying tube → buffer bottle → absorption bottle, the absorption liquid is NaOH or Na 2 CO 3 Solution) to absorb the SO generated by the reaction 2 And HCl gas. After the addition is complete, start to heat slowly when no bubbles are released, and heat to about 80°C, after a constant temperature of 1.5h, when no obvious bubbles are released, stop heating.

[0018] Add 0.04mol hexadecyl alcohol, and add 20ml toluene, gradually increase the temperature to about 120℃, keep constant temperature for 1h, when no obvious bubbles are released, stop heating; change the dev...

Embodiment 2

[0020] Take 0.04 mol of abietic acid, add it to a 250ml flask, add 20ml of toluene, start the stirring device, and completely dissolve the abietic acid. Take 0.02 mol of thionyl chloride, add it to the dropping funnel, add it dropwise to the flask, control the dropping rate of thionyl chloride, and complete the addition in about 45 minutes. At the same time, use a gas absorption device with a calcium chloride drying tube (drying tube → buffer bottle → absorption bottle, the absorption liquid is NaOH or Na 2 CO 3 Solution) to absorb the SO generated by the reaction 2 And HCl gas. After the addition is complete, start to heat slowly when no bubbles are released, and heat to about 100°C. After a constant temperature for 2 hours, when no obvious bubbles are released, stop heating.

[0021] Add 0.02mol dodecanol, and add 20ml toluene, gradually increase the temperature to about 90℃, keep the temperature for 1h, after no obvious bubbles are released, heat up and steam to remove the tolu...

Embodiment 3

[0023] Take 0.04 mol of dehydroabietic acid, add it to a 250ml flask, add 20ml of toluene, start the stirring device, so that the rosin acid is completely dissolved. Take 0.05 mol of thionyl chloride, add it to the dropping funnel, add it dropwise to the flask, control the dropping rate of thionyl chloride, and complete the addition in about 45 minutes. At the same time, use a gas absorption device with a calcium chloride drying tube (drying tube → buffer bottle → absorption bottle, the absorption liquid is NaOH or Na 2 CO 3 Solution) to absorb the SO generated by the reaction 2 And HCl gas. After the addition is complete, start to heat slowly when no bubbles are released, and heat to about 70°C. After a constant temperature for 3 hours, when no obvious bubbles are released, stop heating.

[0024] Add 0.04mol myristyl alcohol, and add 20ml of toluene, gradually increase the temperature to about 130°C, keep the temperature for 2h, and stop heating after no obvious bubbles are relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com