Purification method for gas mixture

A gas mixture and mixture technology, which is applied in chemical instruments and methods, liquefaction, inorganic chemistry, etc., can solve the problems that the exhaust gas cannot be burned at the bottom and is no longer flammable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

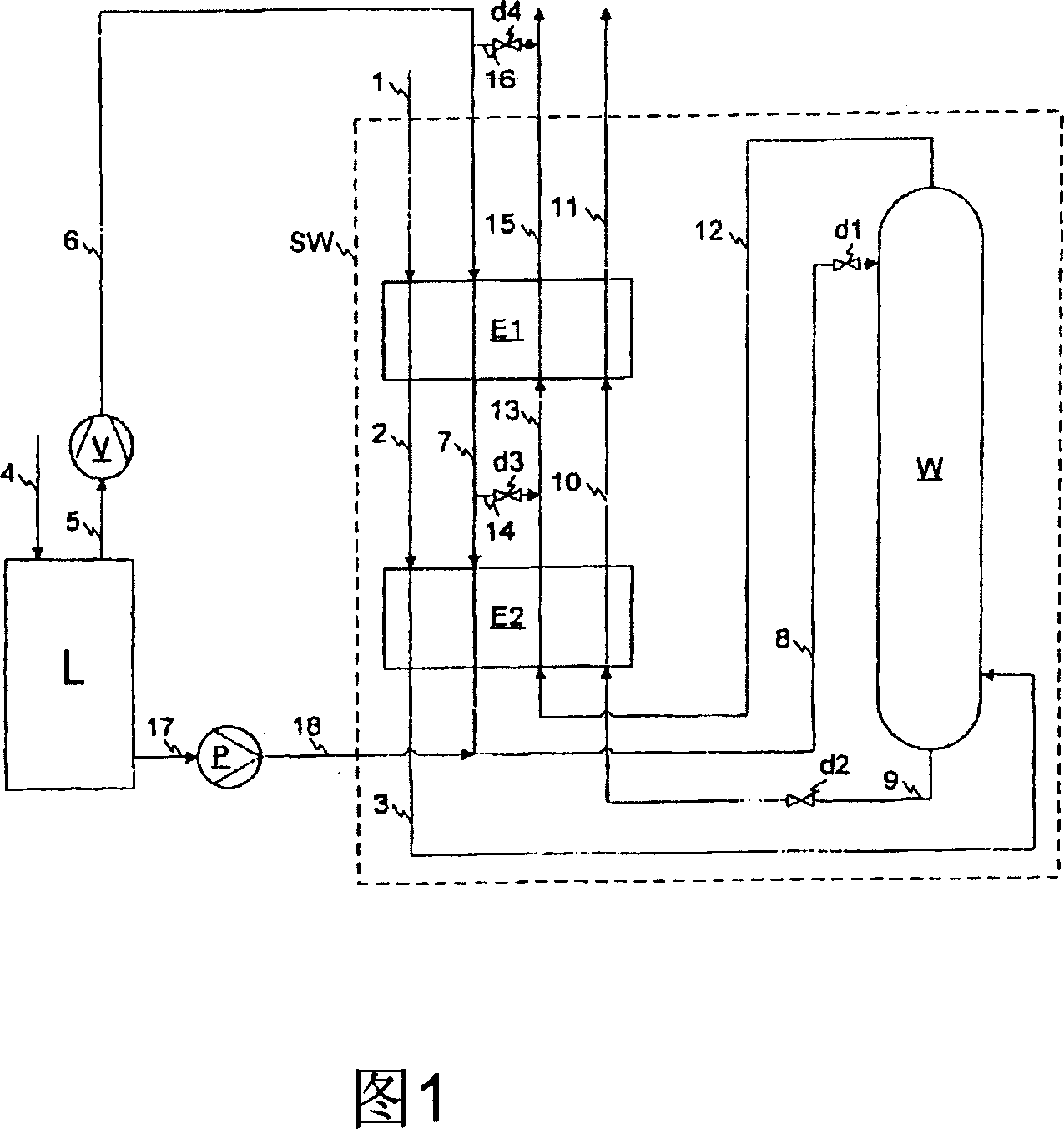

[0015] The exemplary embodiment relates to a process for the production of a feedstock gas for the synthesis of ammonia, wherein the synthesis gas consists essentially of hydrogen, carbon monoxide and methane and, where applicable, argon and nitrogen, which is purified by cryogenic nitrogen scrubbing. To remove unwanted substances (especially carbon monoxide, which is harmful to ammonia synthesis catalysts, but also methane and argon).

[0016] Synthesis gas can be prepared with maximum freedom from water and carbon dioxide in PO-reactors, steam reformers or autothermal reformers and introduced via line 1 at a pressure of about 30 bar and a temperature of about 20 °C into the In the heat exchanger E1 in the low temperature nitrogen scrubber (SW), there, like in the heat exchanger E2 into which the synthesis gas is approached via line 2, it is cooled by means of the process liquid stream to be heated. The cooled synthesis gas is then introduced into the scrubber W via line 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com