Non-cyanogen type electrolytic gold plating bath for bump forming

A bump, non-cyanide technology, used in the field of non-cyanide electrolytic gold plating baths, can solve the problems of short circuit, bump interval or wiring interval narrowing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

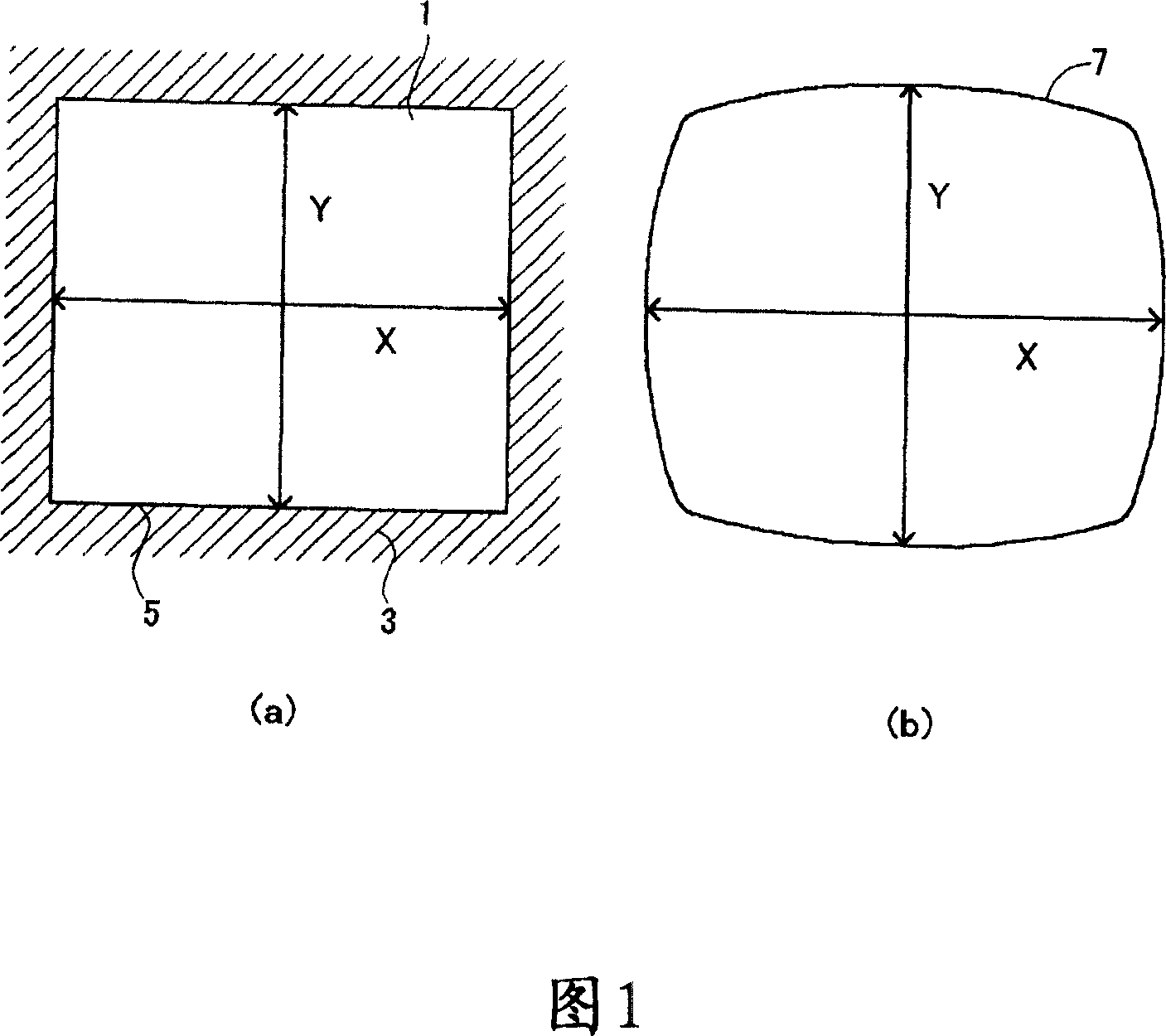

Image

Examples

Embodiment 1~17、 comparative example 1~11

[0062] Prepare the non-cyanide electrolytic gold plating bath according to the combination shown in Table 1 to Table 4. The unit of the compounding concentration of each raw material is g / L unless otherwise specified. But Na 3 Au(SO 3 ) 2 Indicates the concentration of Au amount, Na 2 SO 3 means SO 3 Amount concentration, Na 2 SO 4 means SO 4 amount of concentration.

[0063] A silicon wafer having bump openings patterned with a novolak-based positive photoresist was used as the object to be plated. The cross-sectional composition of the pre-plating surface of the silicon wafer is gold sputtered film / TiW / SiO 2 . The object to be plated was immersed in 1 L of the prepared non-cyanide electrolytic gold plating bath, and energized to form an electroplated film having a film thickness of 15 μm. Furthermore, the current efficiency of non-cyanide electrolytic gold plating baths is typically 100% under stable plating operating conditions.

[0064] After forming a film wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com