High oil absorption resin and its preparation method

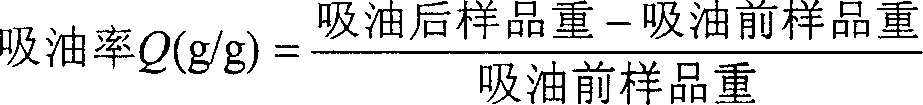

A technology of super oil-absorbing resin and rubber, applied in the field of super oil-absorbing resin and its preparation, can solve the problem that there is no waste tire rubber powder and the like, and achieve the effects of high mechanical strength, solving environmental problems and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Before the reaction, 100 parts of waste tire rubber powder was dissolved in 50 parts of liquid paraffin. In a four-neck round bottom flask equipped with a stirrer, a condenser, a thermometer, and an inert gas inlet tube, add 250 parts of deionized water, 0.1 part of gelatin, 0.05 part of tricalcium phosphate and 0.025 part of sodium lauryl sulfate. Under the protection of gas such as nitrogen, raise the temperature to 30°C in an oil bath, and after constant temperature for 15 minutes, add 100 parts of the dissolved waste tire rubber powder and 1 part of benzoyl peroxide into the four-necked bottle, and quickly Stir, first raise the temperature to 60°C for 2 hours, then slow down the stirring speed, maintain at 350rpm, raise the temperature to 70°C and keep the temperature constant for 4 hours, after the reaction is complete, raise the temperature to 80°C for 1 hour to finish the reaction. After filtration, the product is washed three times with dilute hydrochloric acid ...

Embodiment 2

[0031] Before the reaction, 100 parts of waste tire rubber powder was dissolved in 75 parts of liquid paraffin. In a four-necked round-bottom flask equipped with a stirrer, a condenser, a thermometer, and an inert gas inlet tube, add 325 parts of deionized water, 0.1 part of gelatin, 0.05 part of phosphoric acid tris and 0.025 part of sodium lauryl sulfate. For example, under the protection of nitrogen, raise the temperature in an oil bath to 35°C, keep the temperature for 20 minutes, add 100 parts of the dissolved waste tire rubber powder, 3 parts of divinylbenzene, and 1 part of azobisisobutyronitrile into the four-necked bottle, Stir rapidly under the protection of nitrogen, first raise the temperature to 60°C for 2 hours, then slow down the stirring speed, maintain at 400rpm, raise the temperature to 70°C and keep the temperature for 6 hours, wait until the reaction is complete, then raise the temperature to 80°C for 1 hour of aging, and end the reaction. After filtration,...

Embodiment 3

[0038] Before the reaction, 85 parts of waste tire rubber powder and 15 parts of EPDM were dissolved in 100 parts of liquid paraffin. In a four-neck round bottom flask equipped with a stirrer, a condenser, a thermometer, and an inert gas inlet tube, add 500 parts of deionized water, 0.1 part of gelatin, 0.05 part of tricalcium phosphate and 0.025 part of sodium lauryl sulfate. Under the protection of gas such as nitrogen, raise the temperature to 40°C in an oil bath, and keep the temperature for 20 minutes, then mix 85 parts of the dissolved waste tire rubber powder, 15 parts of EPDM, 3 parts of ethylene glycol diacrylate, and 1 part of benzoyl peroxide. Put it into a four-neck bottle, stir rapidly under the protection of nitrogen, reduce the stirring speed after 2 hours of reaction, maintain at 400rpm, raise the temperature to 70°C and keep the temperature for 7 hours, after the reaction is complete, raise the temperature to 80°C and mature for 1 hour to end the reaction . A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com