Adjuvant for improving flock glue performance and its preparation method and flock glue containing said adjuvant

A technology of glue and additives, applied in the field of emulsion polymer and flocking glue, which can solve the problems of limited scale production and low adjustability, and achieve the effects of low cost, simple use method and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The formula of the flocking glue performance improvement aid used in this example is: 64.5 parts by weight of glycerol, 1.3 parts by weight of pentaerythritol, 18.8 parts by weight of acrylate emulsion with a solid content of 55% and a glass transition temperature of -25°C, 15.4 parts by weight Parts of water. According to this formula, first dissolve pentaerythritol in water, slowly add glycerol to the above amount of acrylate emulsion under stirring, continue stirring for 10 minutes after adding, and then slowly stir the dissolved pentaerythritol solution while stirring Add to the above-mentioned compound and mix well.

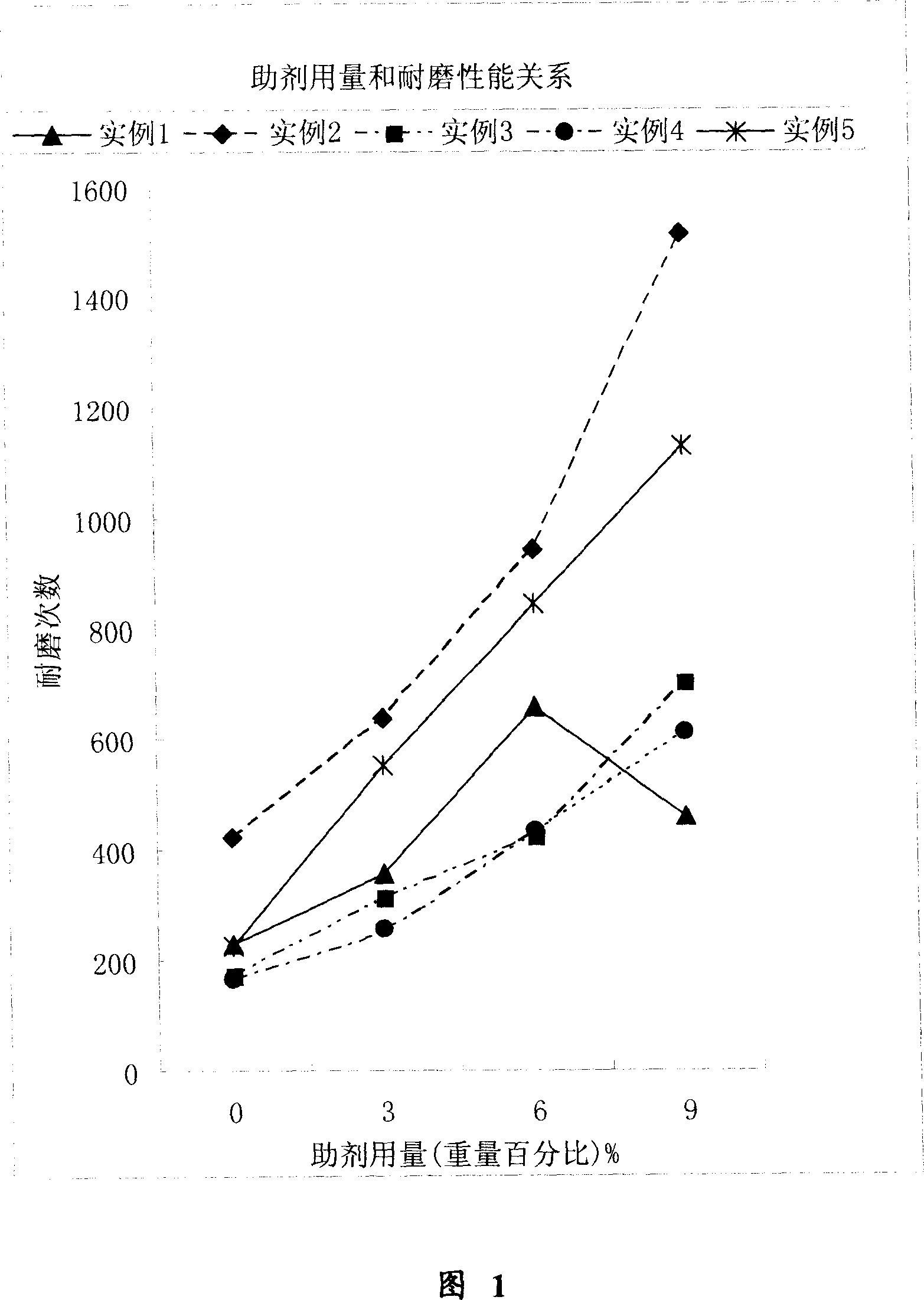

[0042] Add 3, 6, 9 parts by weight of the flocking glue performance improvement auxiliary agent obtained in this example to 100 parts by weight of the flocking glue A202 produced by Aiko Chemical without changing the amount of each auxiliary agent of the glue, and you can get Flocking glue with different properties. It has a good effect on enhancing the y...

Embodiment 2

[0044] The formula of the flocking glue performance improvement aid used in this example is: 65 parts by weight of glycerol, 17.9 parts by weight of fluorocarbon with a solid content of 35%, 1 part by weight of pentaerythritol 1, and 16.1 parts by weight of water. According to this formula, first dissolve the pentaerythritol in water, slowly add the pentaerythritol solution to the glycerol under stirring, continue to stir for 5 minutes after the addition, and then slowly add the fluorocarbon emulsion to the above compound while stirring , Just mix well.

[0045] Add 3, 6, 9 parts by weight of the flocking glue performance improvement auxiliary agent obtained in this example to 100 parts by weight of the flocking glue A202 produced by Aigo Chemical without changing the dosage of each auxiliary agent of the glue. Get flocking glue with different properties. It has a good effect on enhancing the yellowing resistance of the product, improving the conductivity of the final product, and...

Embodiment 3

[0048]The formula of the flocking glue performance improvement aid used in this embodiment is: 26.9 parts by weight of urea, 10.3 parts by weight of fluorocarbon with a solid content of 35%, 12.6 parts by weight of a solid content of 55%, and a glass transition temperature of -25°C Acrylate emulsion, 50.2 parts by weight of water. According to this formula, 10 parts by weight of water are slowly added to the above amount of acrylate emulsion under stirring, and then the above amount of urea is added. After addition, the stirring is continued for 5 minutes, and then the above amount of fluorocarbon emulsion is stirred while stirring. Slowly add to the above compound and mix well.

[0049] Adding the flocking glue performance improvement auxiliary agent obtained in this example to 100 parts by weight of 520 flocking glue at 3, 6, and 9 parts by weight without changing the amount of each auxiliary agent of the glue can obtain planting with different properties. Velvet glue. It has a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com