a li-co 2 Double metal oxide nanosheets for battery and its preparation method and application

A technology of bimetallic oxides and nanosheets, applied in the direction of nanotechnology for materials and surface science, fuel cell half-cells and primary battery half-cells, battery electrodes, etc., can solve the problem of battery failure Large breakthroughs, low conductivity and electrochemical activity, etc., to achieve the effect of diversification of drying methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A Li-CO of the present invention 2 A method for preparing double metal oxide nanosheets for batteries, specifically comprising the following steps:

[0040] (1) Weigh Mg(NO 3 ) 2 and Al(NO 3 ) 3 9H 2 O is put into deionized water to obtain mixed metal salt solution, and the total metal ion concentration is 10mmol L -1 , the molar ratio of magnesium ions and aluminum ions is 1:2;

[0041] (2) Add urea to the mixed metal salt solution, and the quality of urea is 2 times that of the mixed metal salt;

[0042] (3) Heating the mixed dispersion to 80°C for hydrothermal reaction for 24 hours;

[0043](4) Centrifuge the product obtained in step (3), and repeatedly wash with deionized water until neutral, then freeze-dry for 48 hours;

[0044] (5) Calcining the product obtained in step (4) in a high-temperature box furnace under an air atmosphere at a temperature of 400°C for 12 hours to obtain Li-CO 2 Double metal oxide nanosheets for batteries.

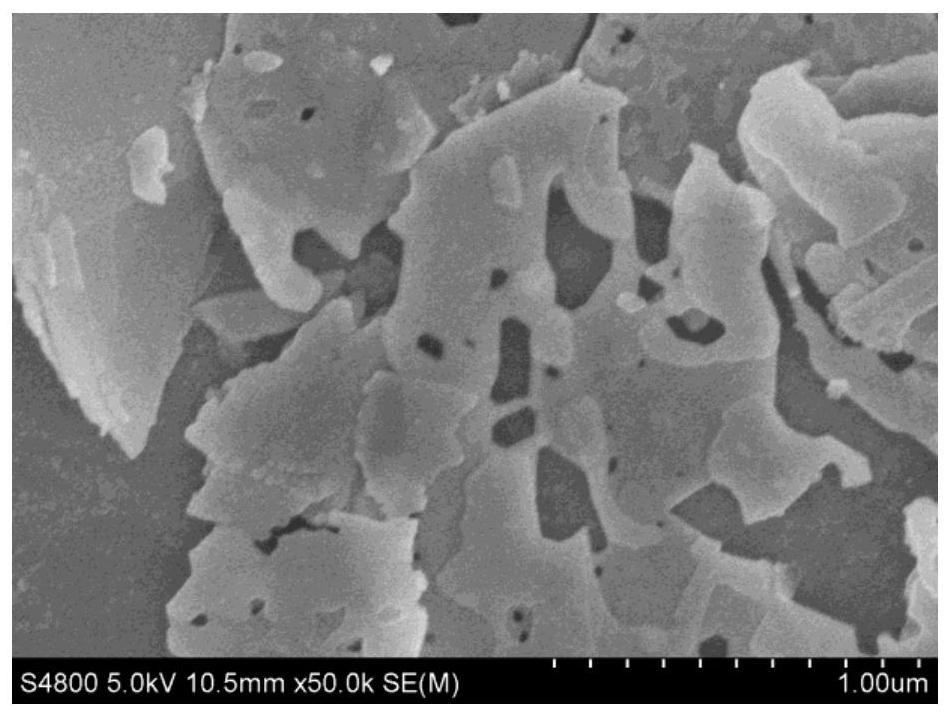

[0045] Such as figu...

Embodiment 2

[0047] A Li-CO of the present invention 2 A method for preparing double metal oxide nanosheets for batteries, specifically comprising the following steps:

[0048] (1) Weigh NiCl 2 ·6H 2 O and MnCl 3 Put into deionized water to obtain mixed metal salt solution, the total metal ion concentration is 50mmol L -1 , the molar ratio of nickel ion and manganese ion is 5:1;

[0049] (2) add urea in mixed metal salt solution, urea quality is 6.6 times of mixed metal salt;

[0050] (3) Heat the mixed dispersion to 160°C for hydrothermal reaction for 5 hours;

[0051] (4) Centrifuge the product obtained in step (3), wash it repeatedly with deionized water until it is neutral, and dry it at 60°C for 24 hours;

[0052] (5) Calcining the product obtained in step (4) in a high-temperature box furnace under an air atmosphere at a temperature of 800°C for 1 hour to obtain Li-CO 2 Double metal oxide nanosheets for batteries.

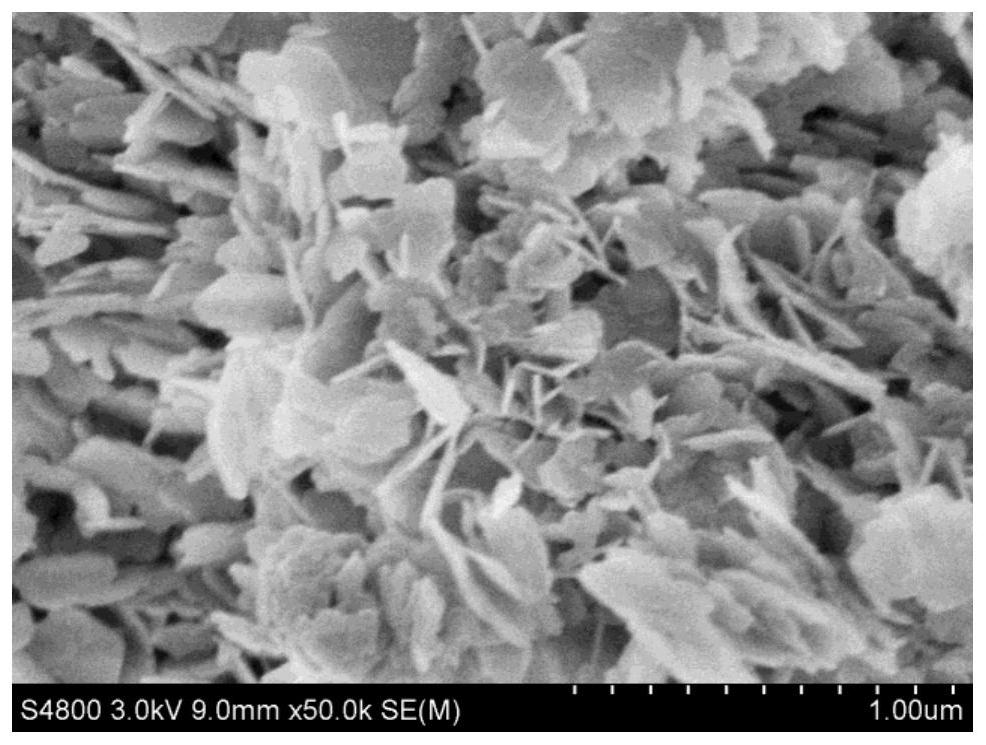

[0053] Such as figure 2 Shown, the Li-CO prepared in Examp...

Embodiment 3

[0055] A Li-CO of the present invention 2 A method for preparing double metal oxide nanosheets for batteries, specifically comprising the following steps:

[0056] (1) Weigh CuCl 2 and VCl 3 Put into deionized water to obtain mixed metal salt solution, the total metal ion concentration is 50mmol L -1 , the molar ratio of copper ion and vanadium ion is 4:1;

[0057] (2) adding hexamethylenetetramine to the mixed metal salt solution, the quality of hexamethylenetetramine is 3 times that of the mixed metal salt;

[0058] (3) Heat the mixed dispersion to 120°C for hydrothermal reaction for 12 hours;

[0059] (4) The product obtained in step (3) was centrifuged, washed repeatedly with deionized water until neutral, and then vacuum-dried at 60°C for 24 hours;

[0060] (5) The product obtained in step (4) is calcined in an air atmosphere in a high-temperature box furnace at a temperature of 600°C for 12 hours to obtain Li-CO 2 Double metal oxide nanosheets for batteries.

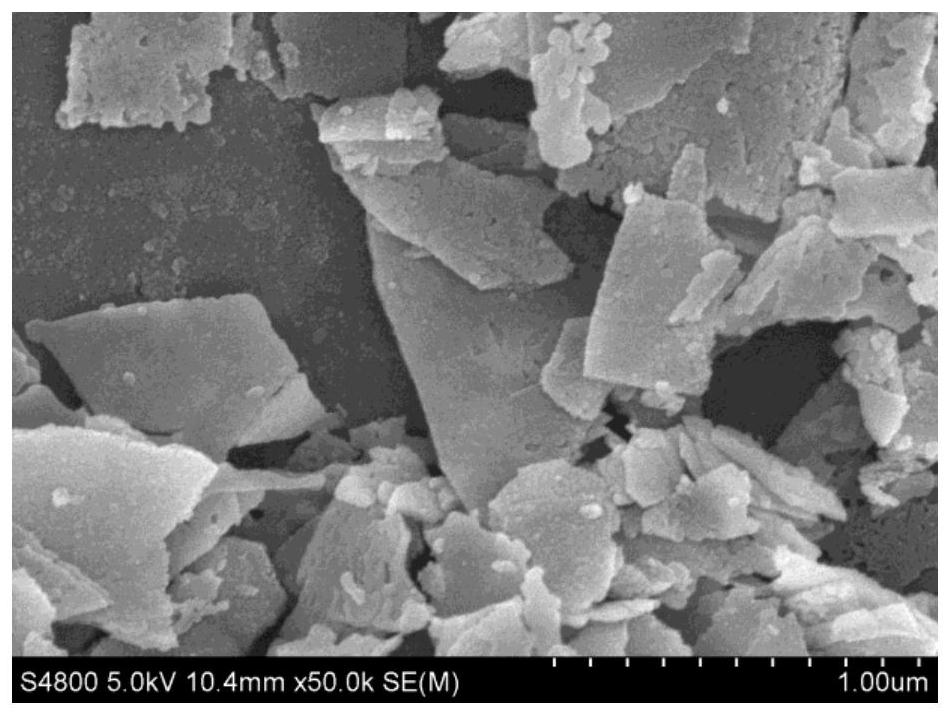

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com