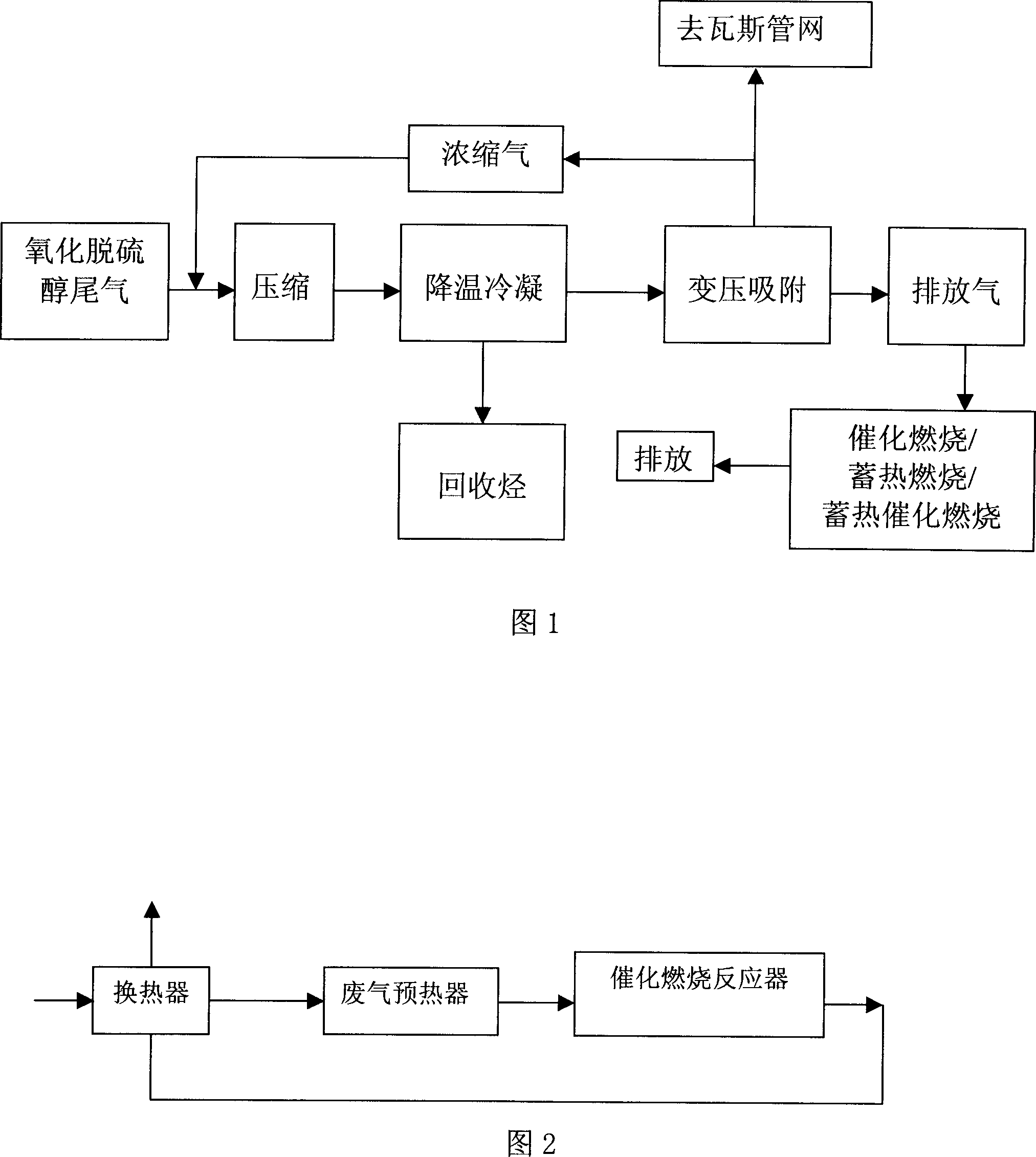

Method for processing light hydrocarbons oxidation sweetening tail gas

A technology for oxidative sweetening of mercaptans and light hydrocarbons, applied in chemical instruments and methods, separation methods, steam condensation, etc., can solve problems such as economic decline and increase in operating costs, and achieve high total recovery rate, improved recovery rate, achieve maximum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

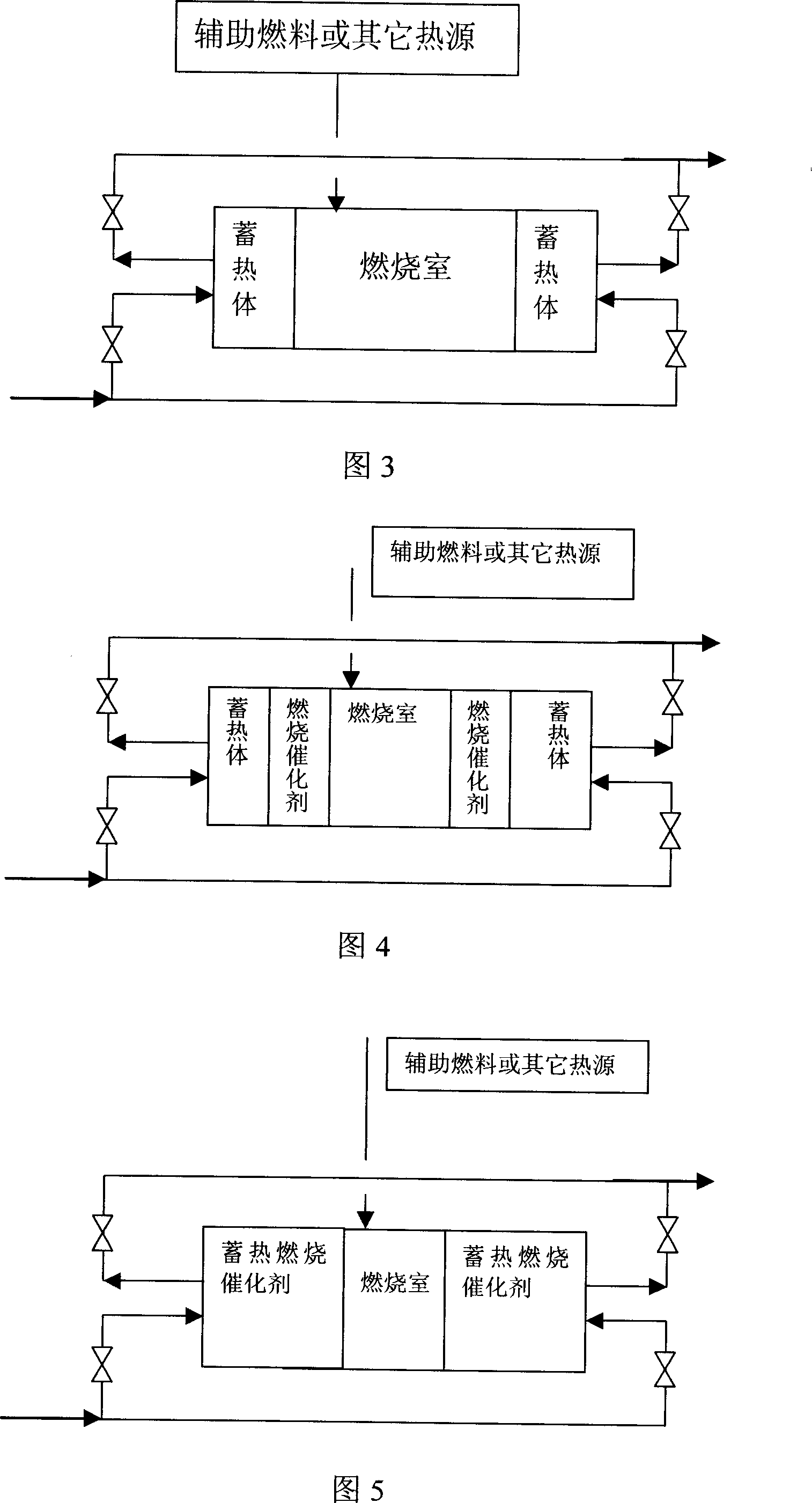

Method used

Image

Examples

Embodiment 1

[0023] The tail gas of a certain company's gasoline air oxidation desulphurization, containing 32v% of hydrocarbons, the exhaust temperature is 53°C, the oxygen content is 17v%, and the average ambient temperature is 25°C. Firstly, the tail gas is compressed to 6.0MPa in stages, cooled with circulating cooling water between stages, and the temperature of the last stage is cooled to 40°C, and the condensed hydrocarbons are recovered. The hydrocarbon content of the compressed and condensed tail gas is 7.5v%. After compression and condensation, the exhaust gas is subjected to pressure swing adsorption with two towers of activated carbon, and the volumetric space velocity of the pressure swing adsorption bed is 5000h -1 When the exhaust gas from the adsorption process reaches 7000μL / L, it switches to regeneration operation, the concentrated gas is decompressed and condensed, and the total hydrocarbon recovery rate is above 95v%. The pressure swing adsorption exhaust gas is purified by...

Embodiment 2

[0025] The tail gas of a certain enterprise gasoline air oxidation desulphurization, containing 32v% of hydrocarbons, the exhaust temperature is 53°C, the oxygen content is 16v%, and the average ambient temperature is 25°C. Firstly, the tail gas is compressed to 6.0MPa in stages, cooled with circulating cooling water between stages, and the temperature of the last stage is cooled to 40°C, and the condensed hydrocarbons are recovered. The hydrocarbon content of the compressed and condensed tail gas is 8.5v%. After compression and condensation, the exhaust gas is subjected to pressure swing adsorption with three towers of activated carbon, and the volumetric space velocity of the pressure swing adsorption bed is 800h -1When the exhaust gas from the adsorption process reaches 8000μL / L, it is switched to regeneration operation. The concentrated gas is removed from the gas pipe network. After compression cooling and pressure swing adsorption, the total hydrocarbon recovery rate is abov...

Embodiment 3

[0027] Gasoline oxidative desulfurization tail gas of a certain enterprise contains 25v% hydrocarbons, the temperature of the tail gas is 45°C, the oxygen content is 7v%, and the average ambient temperature is -10°C. The tail gas is first compressed to 0.8MPa, and then cooled to 10°C with the company's circulating cooling water and cold air, and the condensed hydrocarbons are recovered. The hydrocarbon content of the compressed and condensed tail gas is 6.2v%. After compression and condensation, the tail gas is subjected to pressure swing adsorption with two towers of activated carbon, and the volumetric space velocity of the pressure swing adsorption bed is 9000h -1 When the total hydrocarbon concentration of the exhaust gas reaches 4500μL / L, it is switched to regeneration operation. The concentrated gas is decompressed and condensed. After compression cooling and pressure swing adsorption, the total hydrocarbon recovery rate is more than 95v%. The pressure swing adsorption exhau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com