Photoetching equipment

A lithography equipment and lithography technology, applied in microlithography exposure equipment, optomechanical equipment, optics, etc., can solve problems such as the influence of exposure accuracy, improve the influence of exposure accuracy, improve alignment offset and light leakage, The effect of reducing the amount of change in the pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

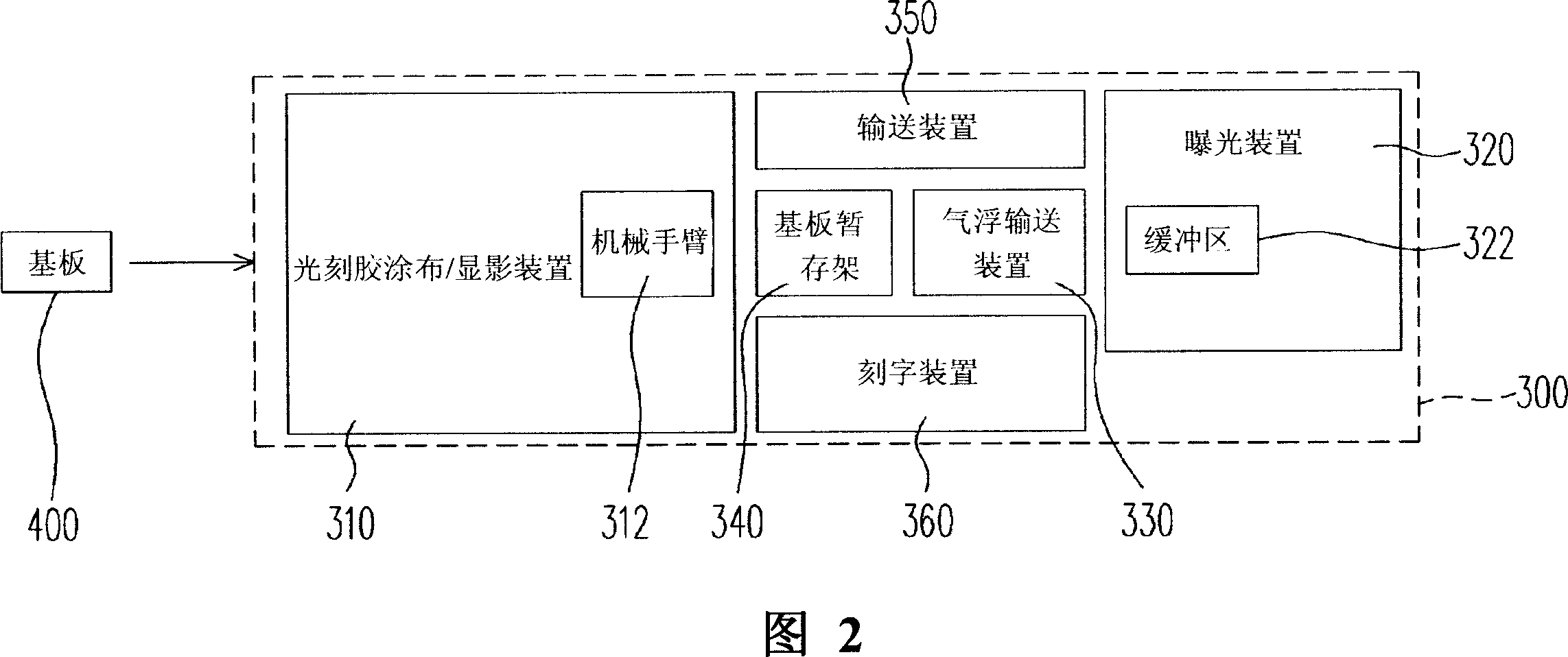

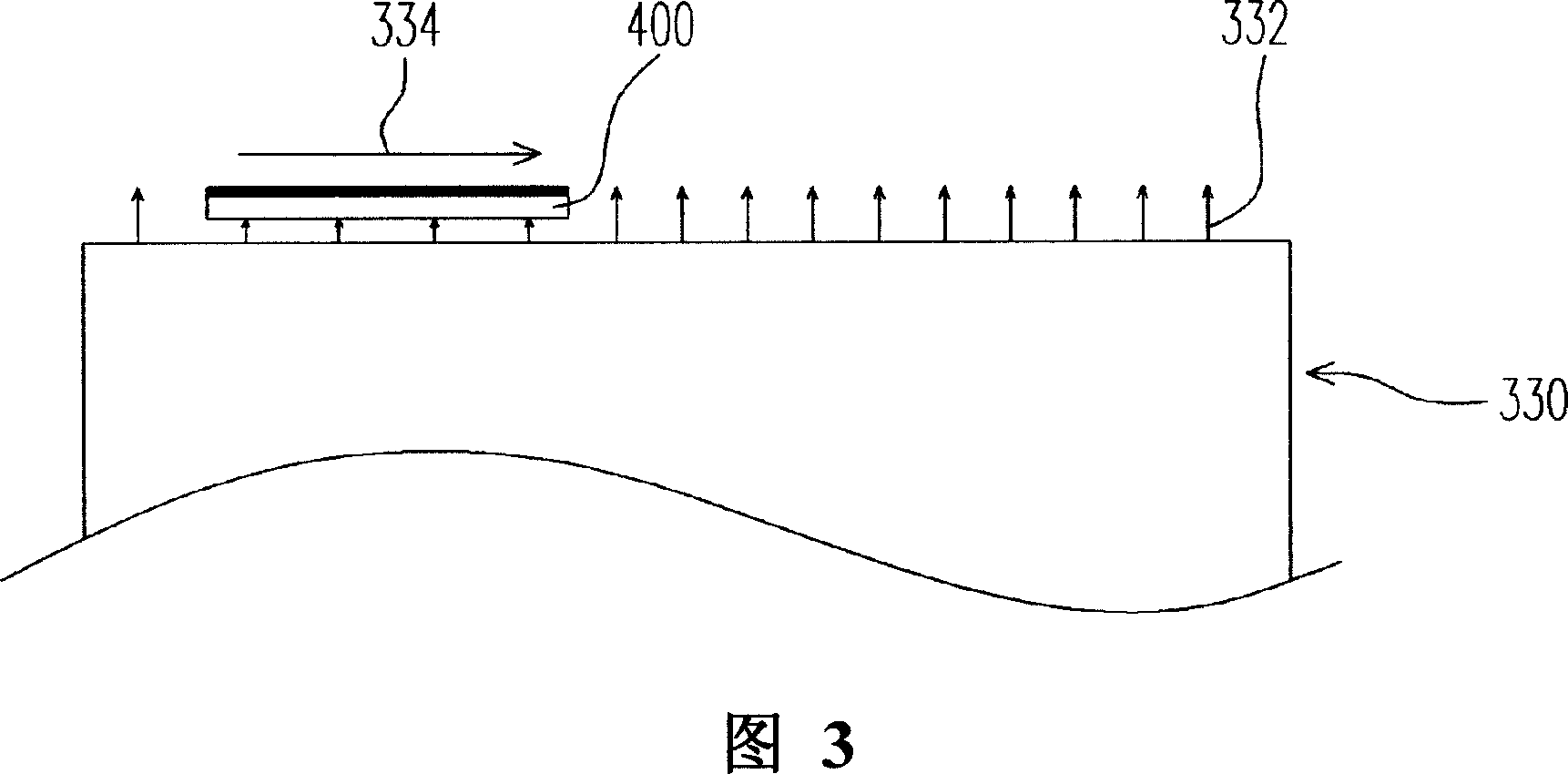

[0038] FIG. 2 is a schematic diagram of a lithographic apparatus according to a preferred embodiment of the present invention, and FIG. 3 is a schematic diagram of the air flotation conveying device in FIG. 2 . Please refer to FIG. 2 and FIG. 3 at the same time, the lithography apparatus 300 of this embodiment is suitable for performing a lithography process on a substrate 400 . The photolithographic equipment 300 includes a photoresist coating and developing device 310, an exposure device 320, and an air-floating conveying device 330, wherein the air-floating conveying device 330 is arranged between the photoresist coating and developing device 310 and the exposure device 320, and The air flotation transport device 330 is suitable for transporting the substrate 400 into the exposure device 320 . The lithography process using the lithography apparatus 300 will be described in detail later.

[0039] After the substrate 400 is sent to the photoresist coating and developing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com