Acrylic pressure sensitive adhesive having antistatic property

An acrylic pressure-sensitive adhesive, pressure-sensitive adhesive technology, applied in the direction of acidic copolymer adhesives, adhesive types, non-polymer organic compound adhesives, etc., can solve problems such as difficult application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

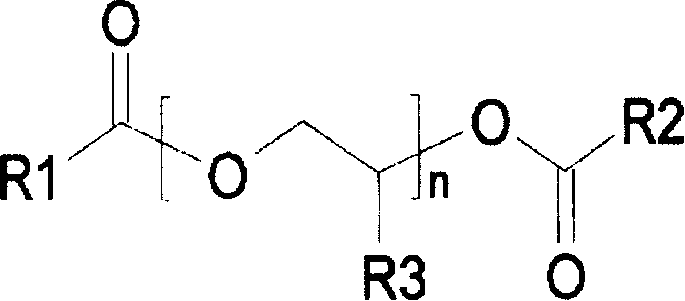

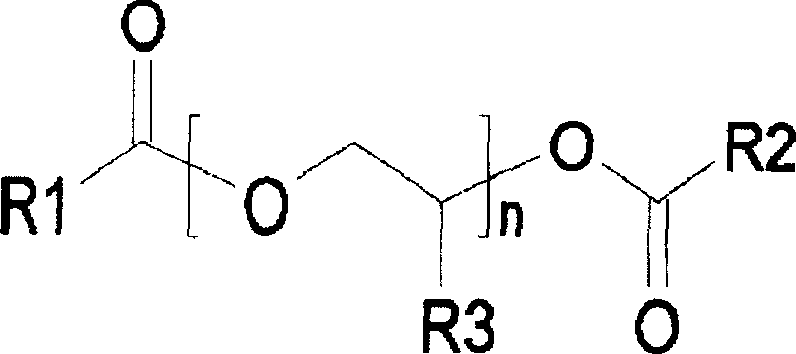

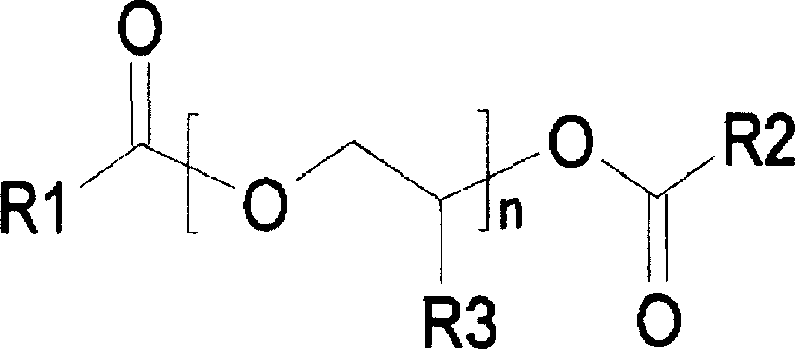

Image

Examples

Embodiment 1

[0074] [embodiment 1] the preparation of acrylic acid copolymer

[0075] A monomer mixture consisting of 98.3 parts by weight of n-butyl acrylate (BA), 0.5 parts by weight of acrylic acid (AA) and 1.2 parts by weight of hydroxyethyl methacrylate (2-HEMA) was added to a 1L Nitrogen was refluxed and the temperature was adjusted in the reactor of the cooling system, and then 100 parts by weight of ethyl acetate (EAc) was added as a solvent. Oxygen was purged by purging with nitrogen for 1 hour while the temperature was maintained at 62°C. After homogenization, 0.03 parts by weight of azobisisobutyronitrile (AIBN), a polymerization initiator diluted to 50% with ethyl acetate, was added. The mixture was reacted for 8 hours to produce an acrylic acid copolymer.

[0076] mixing process

[0077] To 100 parts by weight of the acrylic copolymer prepared above, add 0.5 parts by weight of the toluene diisocyanate adduct of the crosslinking agent trimethylolpropane (TDI-1), 5 parts by w...

Embodiment 2~4

[0081] As shown in Table 1, based on the ingredients of Example 1, the contents of some ingredients were adjusted up or down to carry out the copolymerization reaction. The preparation, mixing and lamination of the acrylic copolymer was carried out in the same manner as described in Example 1 except that the mixing process was adjusted up or down. The durability and surface resistance were also detected by the same method as described in Example 1, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cross-linking density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com