Bacteriostatic medical stainless steel ossicle needle and its making process

A manufacturing method and stainless steel technology, applied in the field of medical devices, can solve problems such as poor corrosion resistance and achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

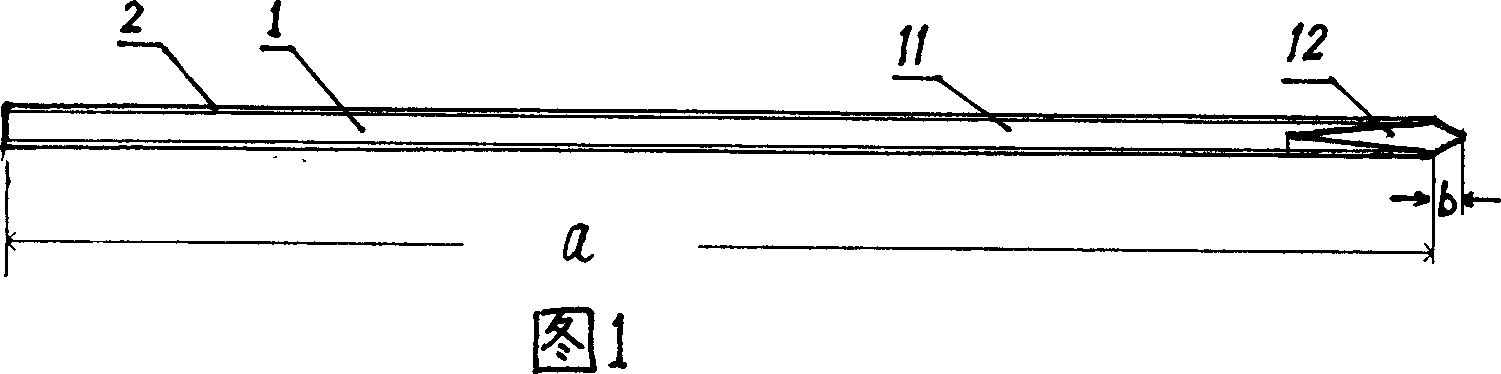

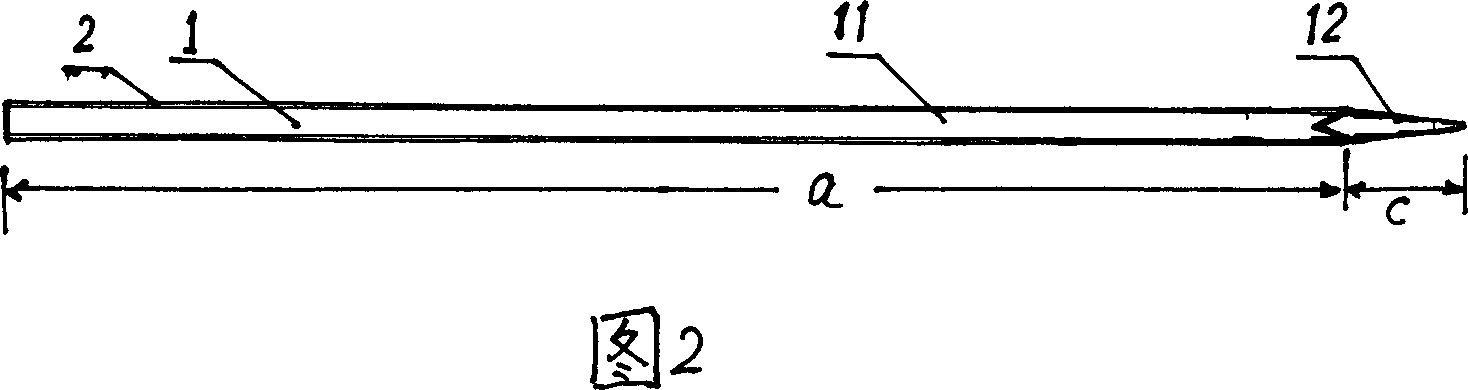

[0031] Referring to Fig. 1 and Fig. 2, this embodiment includes a stainless steel small bone element needle 1. The small bone element needle 1 is composed of a needle handle 11 and a foldable needle head 12. The length a of the needle handle 11 is 203 mm, and the length a of the needle head 12 when folded is b =1mm, and the unfolding time length c=10mm. The surface of the stainless steel small bone element needle 1 is covered with nano-TiO 2 / SiO 2 Composite film 2, nano-TiO 2 / SiO 2 The composite membrane 2 is made of nanoscale titanate and nanoscale silicate. The preparation method is as follows: 1) Degrease the stainless steel small bone element needle 1 (Φ2mm) with acetone, immerse it in the decontamination solution for at least 10 minutes, and the immersion temperature is 70°C-85°C; 2) After washing and drying, soak it in ethanol for later use ; 3) Preparation of nano-TiO by co-hydrolysis of titanate and silicate by sol-gel method 2 / SiO 2 Composite sol, soak the af...

specific Embodiment 2

[0033] The characteristics of this embodiment are: the small bone element needles (Φ2mm) are degreased with acetone, and then immersed in the decontamination solution for 10 minutes at a temperature of 85°C. Pull three times in a sol of butyl titanate and ethyl orthosilicate (Ti:Si=10:1). The wet coating was first dried at 100°C for 5 minutes, then placed in a muffle furnace for heat treatment at 600°C for 30 minutes, and cooled at room temperature for later use.

specific Embodiment 3

[0034] The characteristics of this embodiment are: the small bone element needles (Φ2mm) are degreased with acetone, and then immersed in the decontamination solution for 10 minutes at a temperature of 75°C. Pulled six times in a sol of butyl titanate and ethyl orthosilicate (Ti:Si=7:3). The wet coating was first dried at 100°C for 5 minutes, then placed in a muffle furnace for heat treatment at 300°C for 30 minutes, and then cooled at room temperature for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com