Nanometer biological adhesive and its production process

An adhesive and biological technology, used in adhesives, adhesive types, protein adhesives, etc., can solve the problems of poor adhesive strength, difficult to popularize and apply, poor water resistance, etc., and achieve improved adhesive strength and price. Inexpensive, enhanced adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

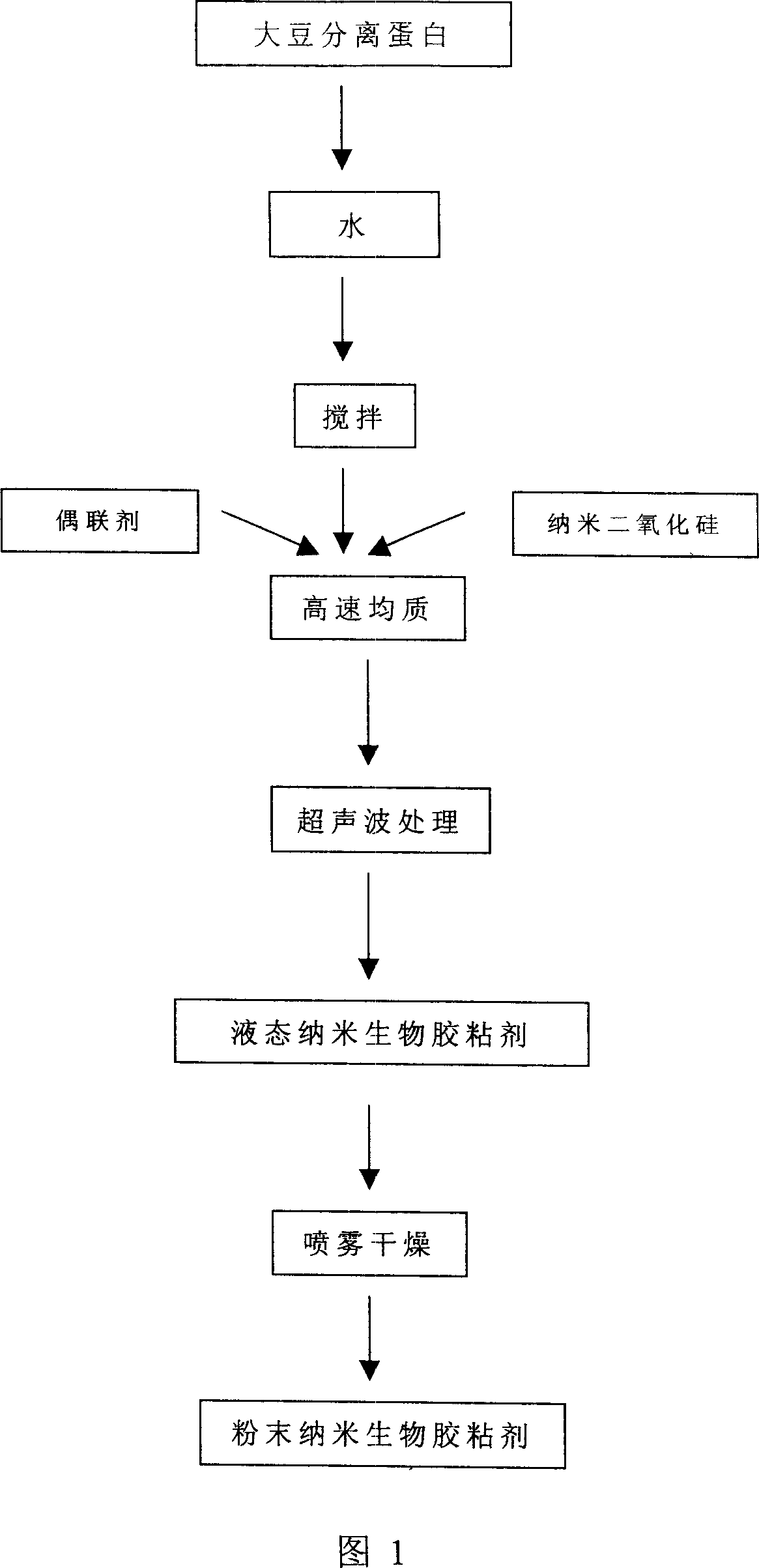

Image

Examples

Embodiment 1

[0019] In the embodiment of the present invention, 10% by weight soybean protein isolate is firstly dispersed in 88.99% by weight of water, and the 94-2 type timing and constant temperature magnetic stirrer is used to stir for 30 minutes to prepare the base material; then slowly add coupling agent to 0.01% by weight and Nano-silica is 1% by weight, and is dispersed for 1 minute at a constant temperature of 50° C. using a high-speed shear emulsifier, and the dispersion speed of the high-speed shear emulsifier is 5000 rpm; finally, ultrasonic treatment is used for 30 minutes to obtain a nano-biological adhesive. It is spray-dried to become a powdered nano-biological adhesive. Spray drying inlet air temperature: 160°C, outlet air temperature: 80°C, processing time: 5 minutes.

Embodiment 2

[0021] In the embodiment of the present invention, 10% by weight soybean protein isolate is first dispersed in 89.98% by weight of water, and the base material is prepared by stirring with a 94-2 type timing constant temperature magnetic stirrer for 40 minutes, and then slowly adding a coupling agent of 0.02% by weight and nanometer Silica is 1% by weight, at a constant temperature of 45°C, dispersed by a high-speed shear emulsifier for 1.5 minutes, and the dispersion speed is 8000 rpm, and finally treated with ultrasonic waves for 25 minutes to obtain a nano-biological adhesive, which is spray-dried to obtain Powdered nano bioadhesive. Spray drying inlet air temperature: 170°C, outlet air temperature: 85°C, drying treatment time: 7 minutes.

Embodiment 3

[0023] In the embodiment of the present invention, first get 10% by weight soybean protein isolate and disperse it in 88.97% by weight of water, and use a 94-2 type timing and constant temperature magnetic stirrer to stir for 45 minutes to prepare the base material; then slowly add coupling agent to 0.03% by weight and Nano-silica is 1% by weight, and is dispersed for 2 minutes at a constant temperature of 55° C. by a high-speed shear emulsifier, and the dispersion speed of the high-speed shear emulsifier is 7500 rpm; finally, ultrasonic treatment is used for 35 minutes to obtain a nano-biological adhesive. It is spray-dried to become a powdered nano-biological adhesive. Spray drying inlet air temperature: 180°C, outlet air temperature: 90°C, processing time: 6 minutes.

[0024] The adhesive strength and water resistance of the nano bio-adhesive prepared by the three embodiments of the present invention are much higher than those of the unmodified soybean protein isolate.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com