Die bonding adhesive tape

A chip bonding and adhesive tape technology, applied in the direction of adhesives, film/sheet adhesives, heat-activated films/sheets, etc., can solve the problem of not significantly reducing the adhesion, increasing the difficulty of picking up chips, and destroying chips And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

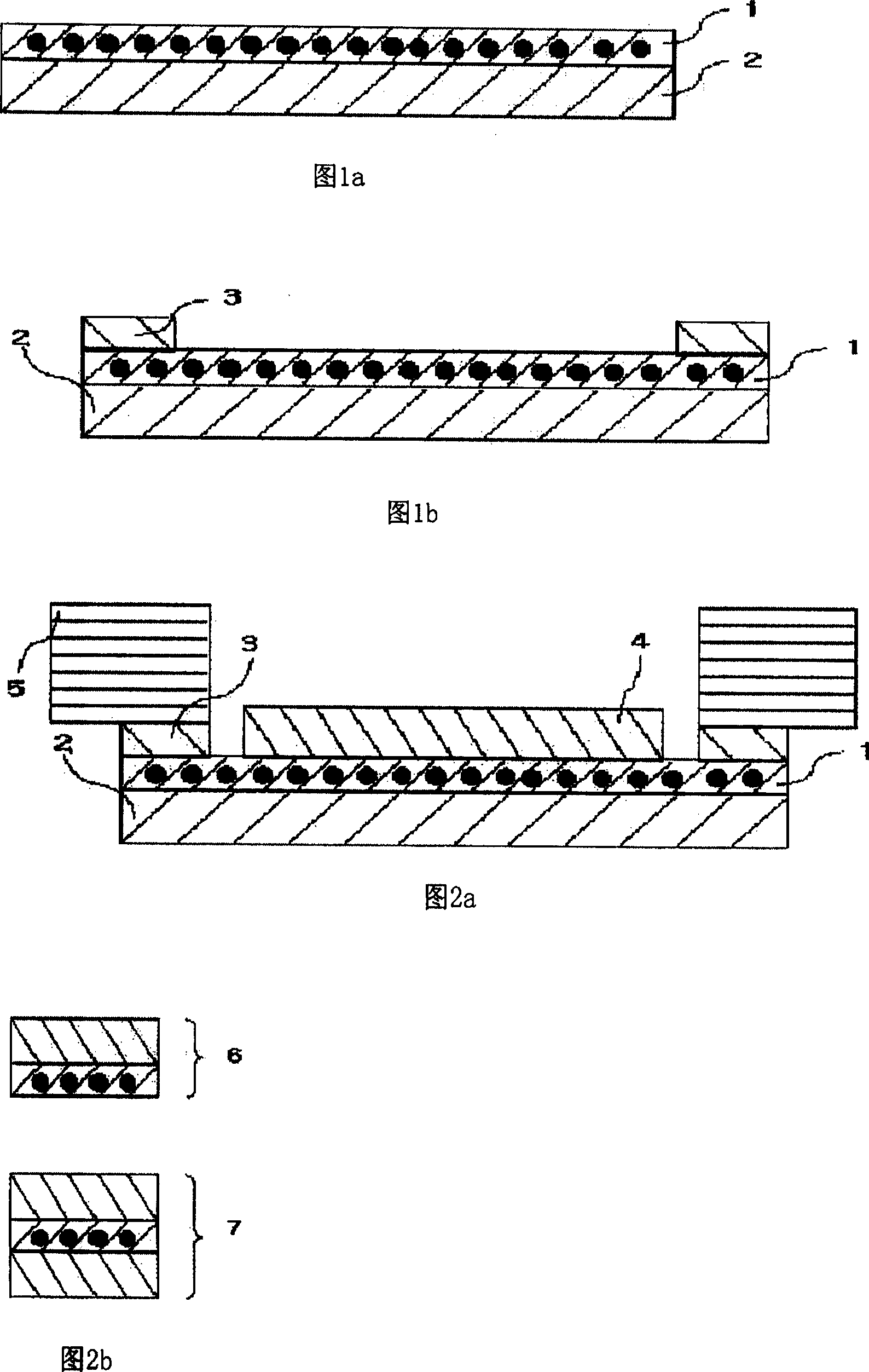

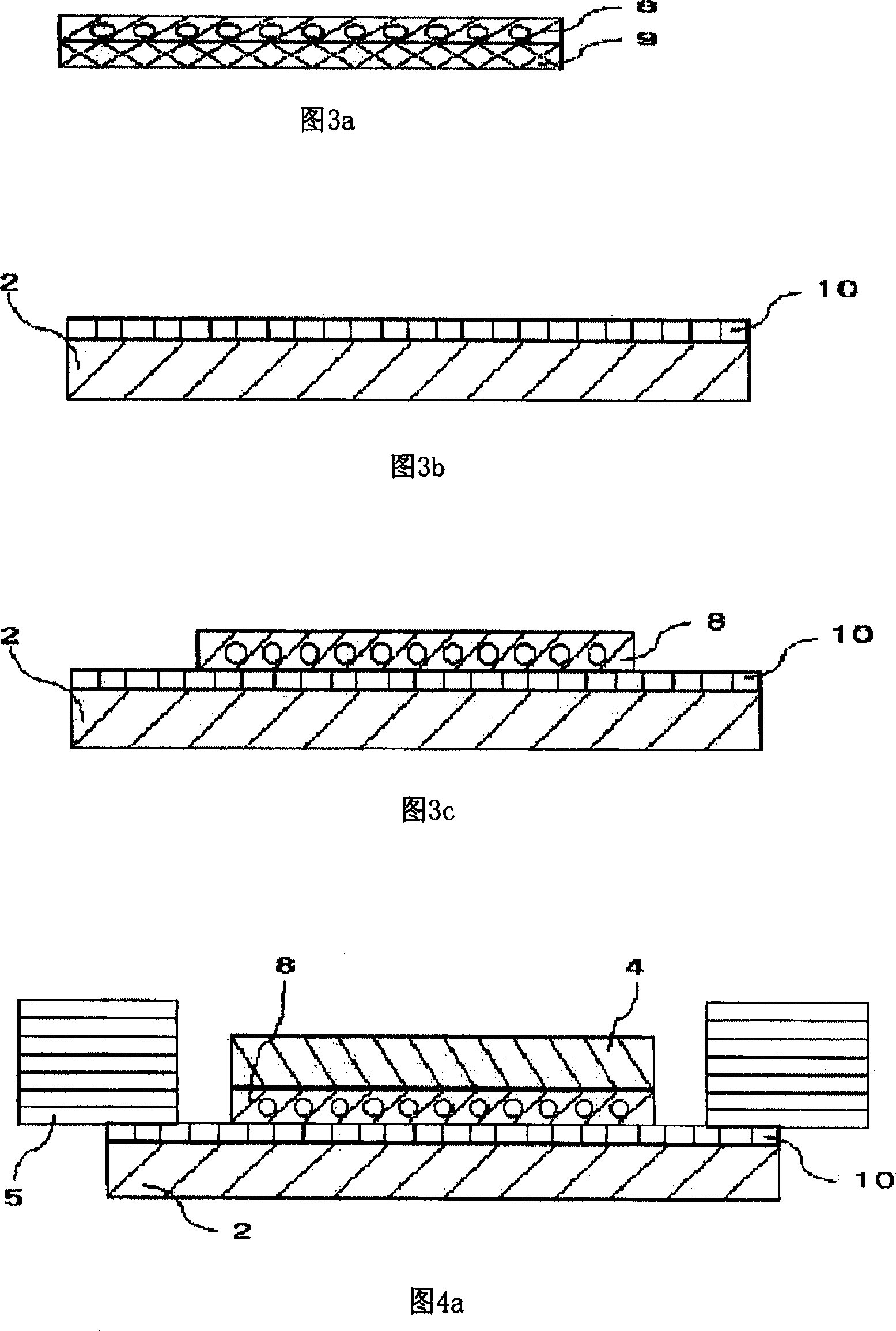

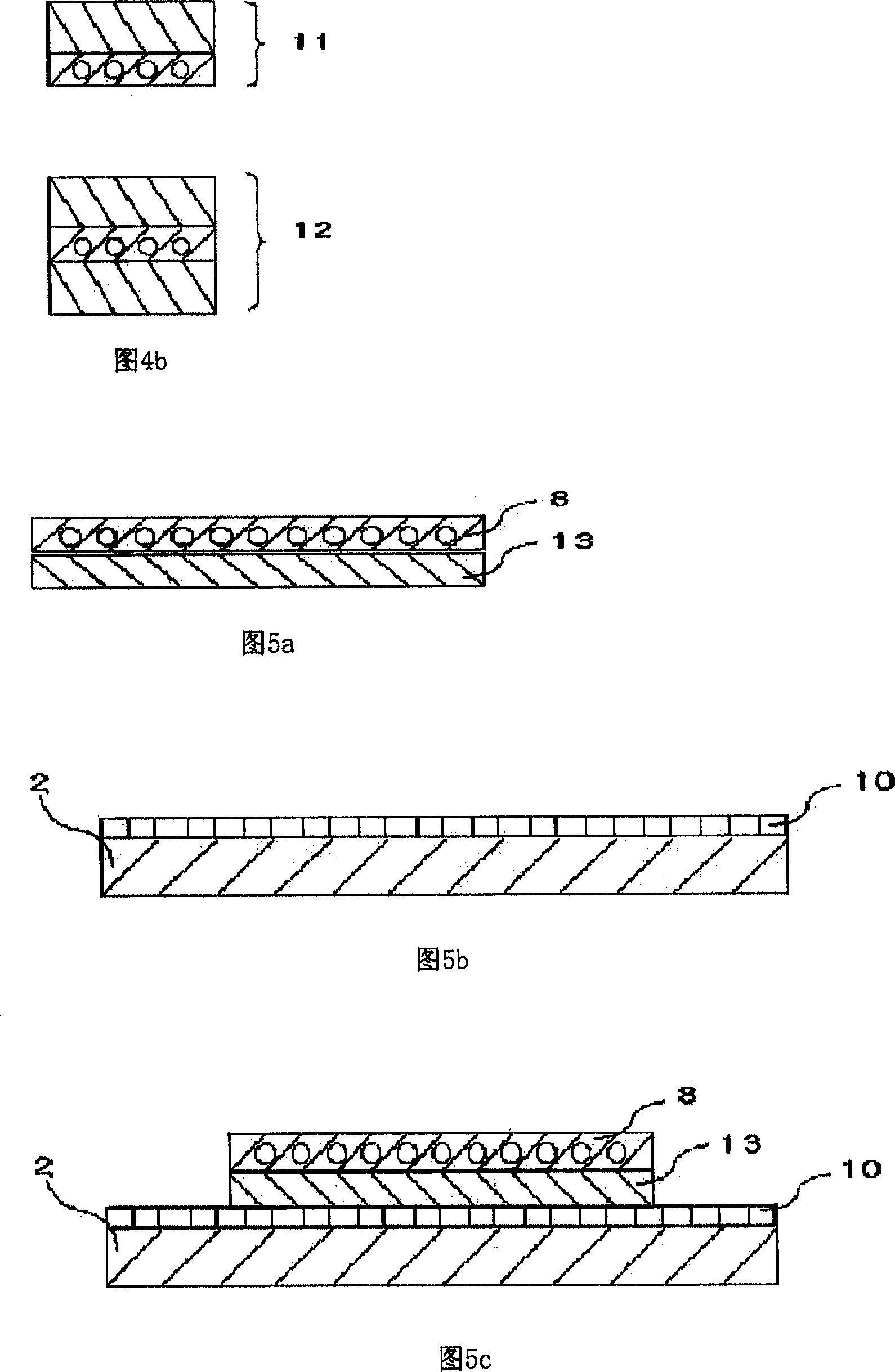

Method used

Image

Examples

manufacture example 1

[0049] [Manufacturing example 1] Manufacture of die-bonding adhesive film 1

[0050] An acrylic curing agent and a curing accelerator are added to a die-bonding adhesive film composition composed of an epoxy resin, a phenolic resin, and an acrylic adhesive solution to cure the epoxy resin. In this way, the epoxy resin and the phenolic resin were mixed at a ratio of 5:3 and stirred for 30 minutes, and then the resulting stirred solution and the acrylic adhesive were mixed at a ratio of 15:45 and stirred for 3 hours. Then add an acrylic curing agent and an epoxy curing accelerator therein and continue stirring for 30 minutes to form a die-bonding adhesive film 1 . As shown in Composition Table 1 below, each component was used after being diluted in an organic solvent at a predetermined ratio.

manufacture example 2

[0051] [Manufacturing example 2] Manufacture of die-bonding adhesive film 2

[0052] The method of manufacturing the die-bonding adhesive film was the same as that of Production Example 1, and then added a UV-curable low-molecular-weight compound in order to increase the adhesion and stirred for 30 minutes to prepare the die-bonding adhesive film 2 .

manufacture example 3

[0053] [Manufacturing example 3] Manufacture of die-bonding adhesive film 3

[0054] The method for producing the die-bonding adhesive film was the same as in Production Example 2, and then a photoinitiator was added for ultraviolet light curing, followed by stirring for 30 minutes to produce a die-bonding adhesive film 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com