Films or structural exterior materials using coating composition having self-cleaning property and preparation method thereof

A composition and self-cleaning technology, applied in radiation-absorbing coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problem of ineffective prevention of urban dust pollution, undesirable, ineffective purification of stains and pollution to achieve excellent self-cleaning performance and excellent pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

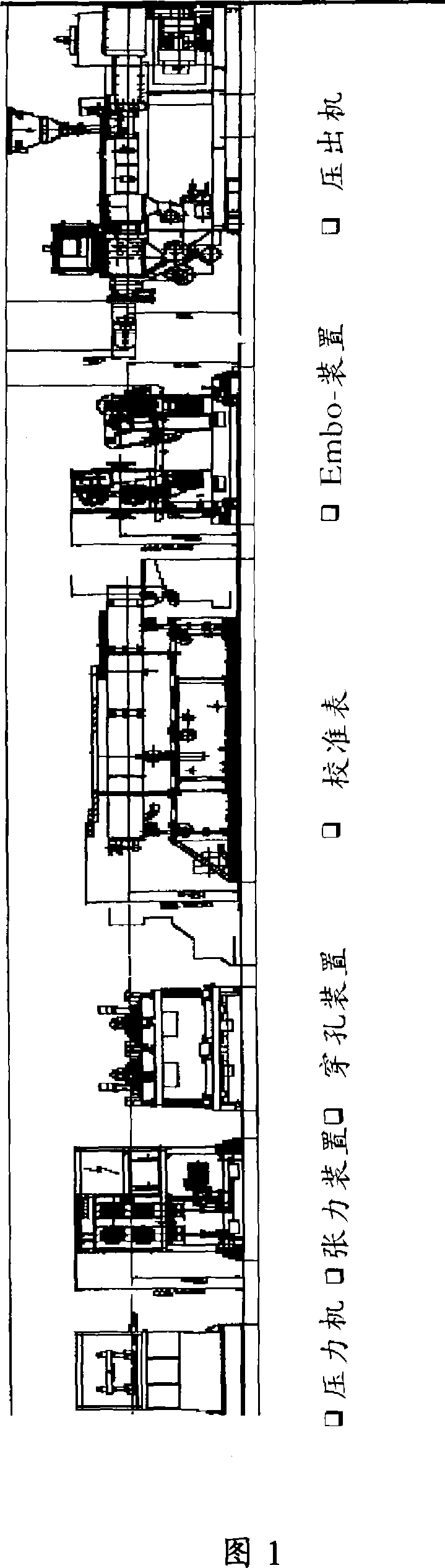

[0103] [Examples 1-7] Coating composition, and advertising paper and construction using the coating composition Preparation of exterior materials

Embodiment 1

[0105] 1-1. Coating composition

[0106] Add 9 wt% of silica dispersion (MA-ST purchased from TLSAN chemical company) with 30% solids content to the reactor, which includes dispersion in methanol (2.7 wt% of silica and 6.3 wt% of methanol) 0.09 wt% of silica particles (Fine Sil, Tokuyama Co.) with an average particle diameter of 1.7 D; 0.01 wt% concentration of 10% nitric acid; 1.01 wt% % water; 18 wt% methanol; and 1.89 wt% glycidoxypropyltrimethoxysilane. After the mixture was reacted at 50° C. for 24 hours, 10 wt % of EA (ethyl acetate), 54.5 wt % of MEK (methyl ethyl ketone) and 5 wt % of toluene were sequentially added. Then, the above mixture was stirred for 1 hour to form a coating composition.

[0107] 1-2. Preparation of building exterior materials with pollution resistance

[0108] The coating composition obtained according to Example 1-1 was applied at a dry thickness of 2 D to vinyl siding products (LG Chemical Co., Ltd., LG Sideon) to produce stain resista...

Embodiment 2

[0110] Example 1 was repeated to prepare vinyl siding with stain resistance, except that a vinyl siding product (LG Chemical Corporation, LG Sideon) was coated with the coating composition at room temperature without the embossing step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com