New-type of carbon tube and its synthesis process

A synthesis method and carbon tube technology, applied in the field of solvothermal synthesis of carbon tubes, can solve the problems of unfriendly environment and high production cost, and achieve the effects of good hydrophilicity, low production cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

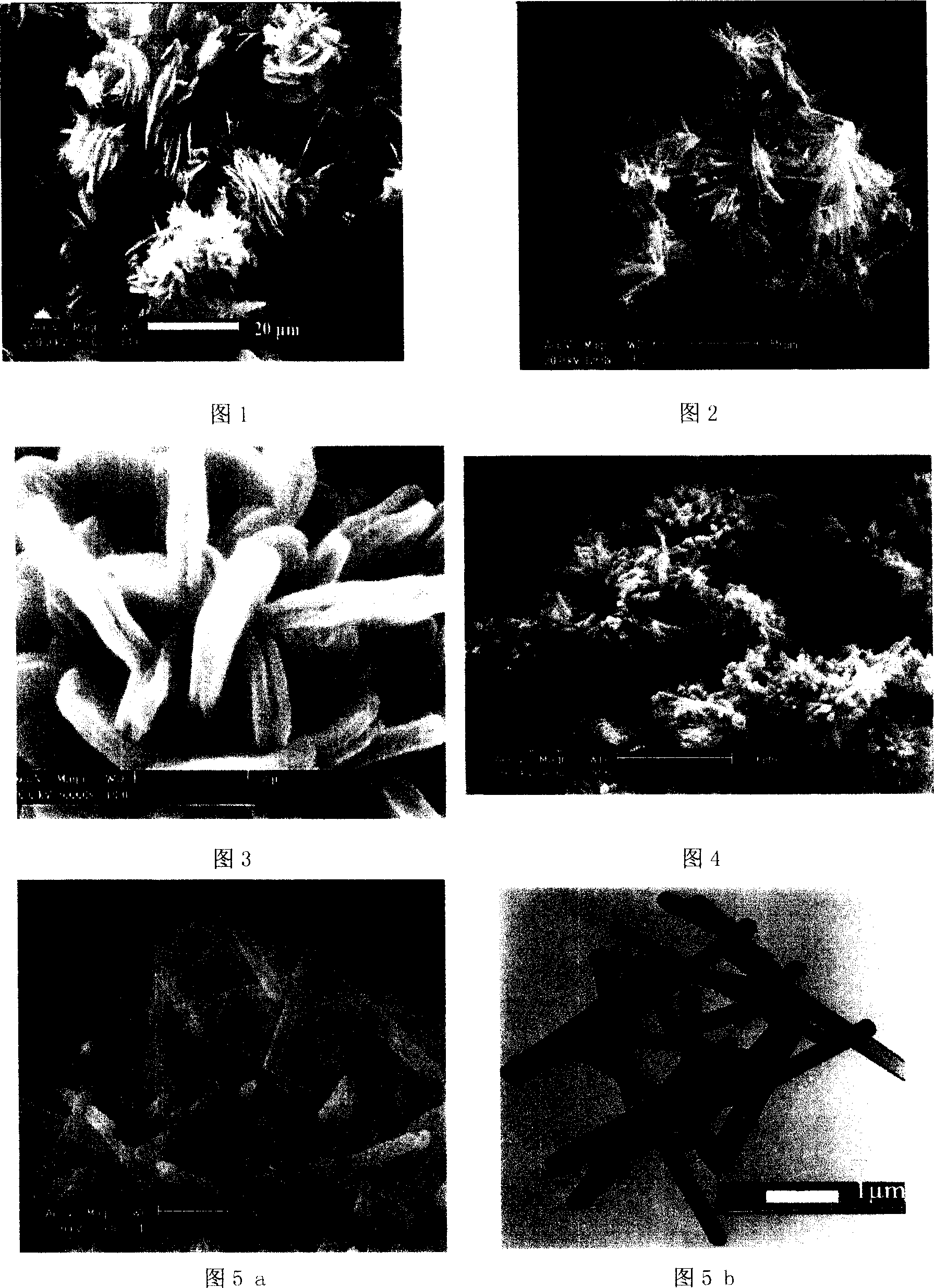

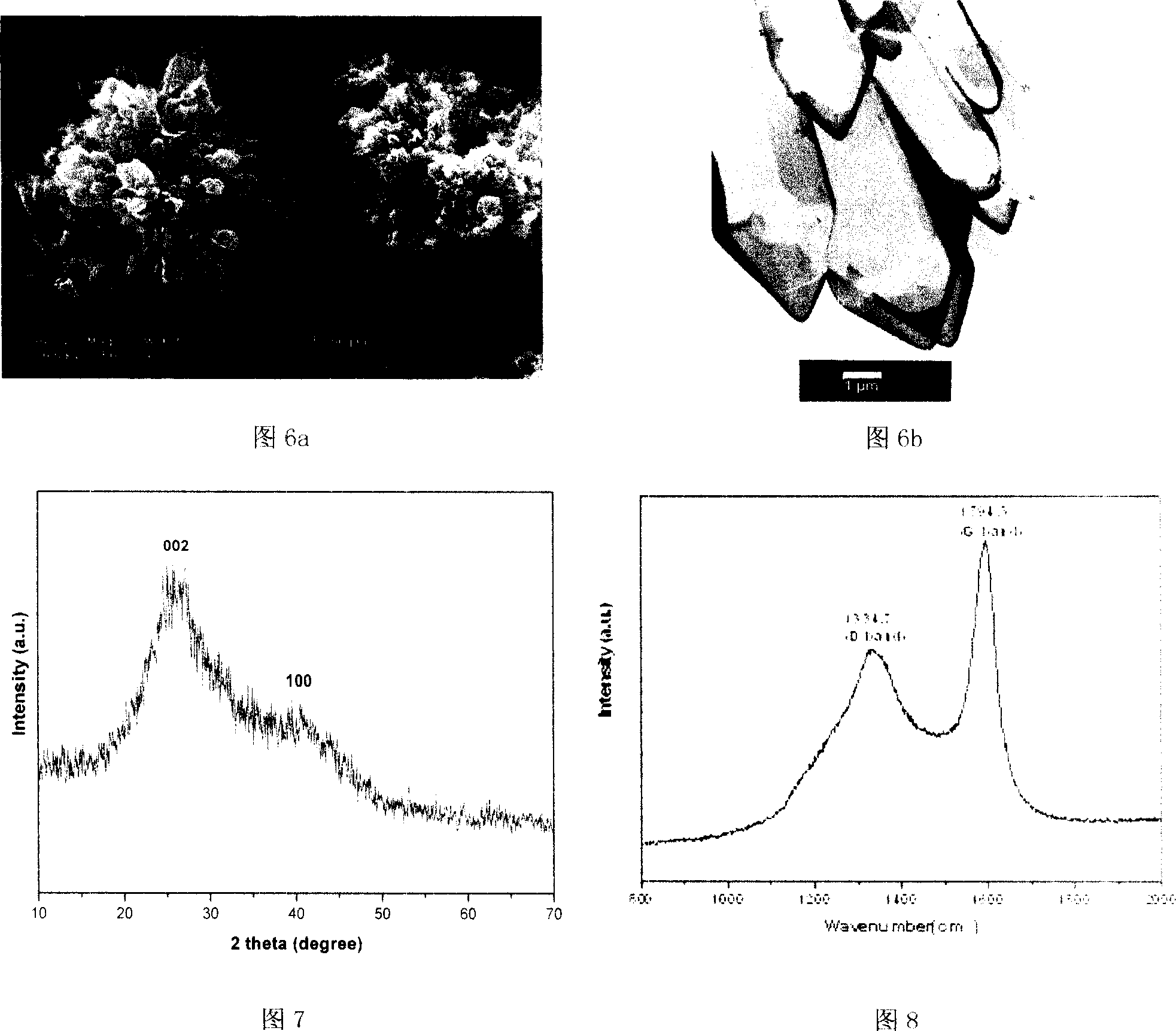

Embodiment 1

[0027] With 4g Zn(CH 3 COO) 2 2H 2 O was used as a catalyst, 40 mL of absolute ethanol was used as a carbon source, put into a 60 mL stainless steel autoclave, heated to 600 °C at a heating rate of 10 °C / min, kept for 15 h, and then naturally cooled to room temperature. After the product was collected from the autoclave, it was washed successively with hydrochloric acid with a concentration of 5%-15%, distilled water and absolute ethanol, and finally the obtained black product was dried in a vacuum dryer at 60° C. for 6 hours. The obtained product was characterized and analyzed by transmission electron microscope (TEM), scanning electron microscope (SEM) and X-ray diffraction (XRD), and it was confirmed that the obtained product was a carbon tube with high purity, and its shape was straight carbon Microtubules, its content is about 95%.

[0028] The inventor selects different raw materials and operating conditions (all the other operating conditions are the same as embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com