Hydrophobic structure and preparation method thereof

A hydrophobic and method-based technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of time-consuming vacuuming, insufficient wear resistance, thick thickness, etc., so as to save the cost of vacuuming Time, hardness and wear resistance protection, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

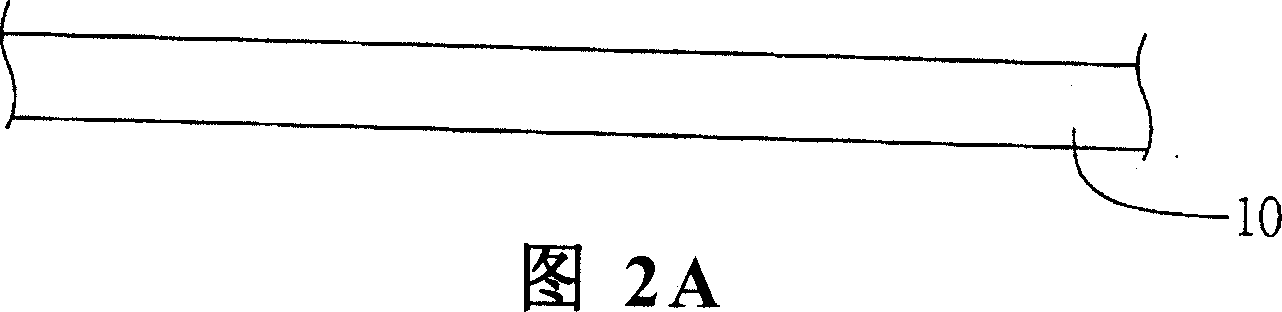

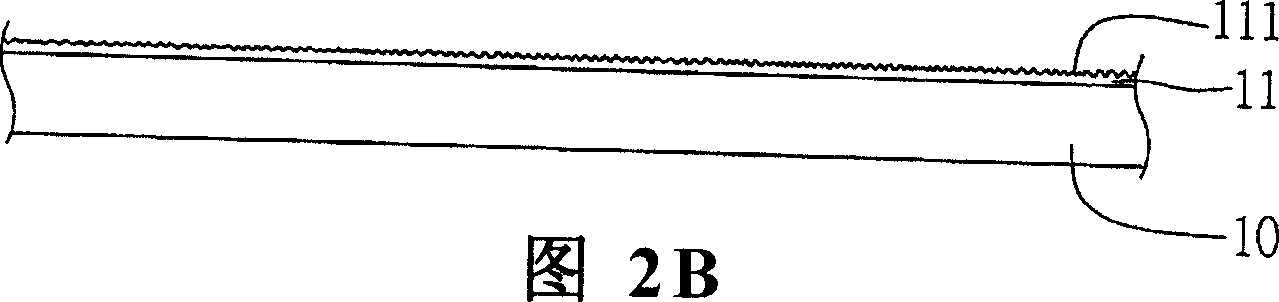

[0043] Prepare a glass substrate with an area size of 6.5 cm×6.5 cm, and pretreat it with plasma generated by compressed dry air at a flow rate of 2 cubic meters per hour. Next, use tetraethoxysilane (TEOS) as the precursor, and helium (He) as the carrier to introduce through the introduction system, and directly coat the surface of the pretreated substrate after interacting with the plasma. SiO formed on 2 The water contact angle of the coating is 18 degrees. Please refer to FIG. 3A and FIG. 3B for the results, which respectively show the schematic diagram of the atomic force microscope of the rough surface 111 of the hard coating 11 of the hydrophobic structure 1 of the present invention, and the schematic diagram of the surface roughness curve, and the hard coating 11 formed by coating the surface of the substrate 10. Among them, the average surface roughness (Ra) of the rough surface 11 can reach 16.6nm.

Embodiment 2

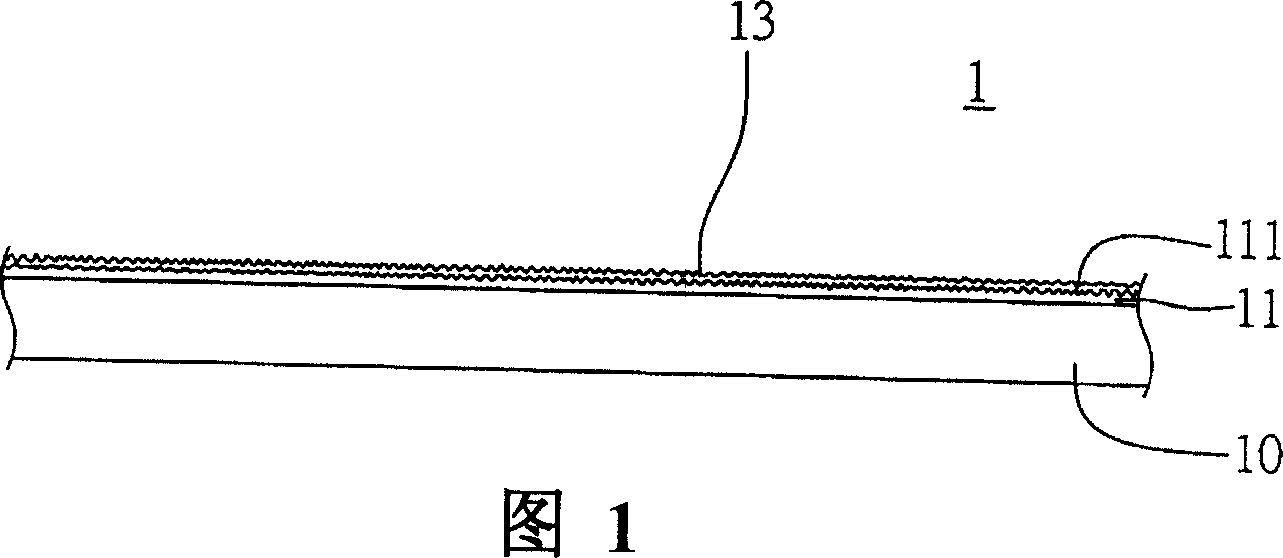

[0045] After repeating the steps of Example 1, in the SiO 2 On the coating layer, heptadecafluorodecyltrimethoxysilane (FAS) was used as the precursor to be placed in a three-necked bottle, and then helium was used as a carrier to introduce into the bottle through the mouth of the three-necked bottle, and the above two gases The mixed gas is drawn from another bottle mouth, and after interacting with the plasma, it is directly coated on the surface of the substrate. Please refer to Figure 4A to Figure 4C for the results, which respectively show the schematic diagram of the atomic force microscope of the hydrophobic structure of the present invention, the surface roughness curve, and the schematic diagram of the hydrophobic angle test. After coating the rough surface of the hard coating 11 to form a hydrophobic coating 13, A hydrophobic structure 1 comprising a hard coating 11 and a hydrophobic coating 13 is formed, and the average surface roughness (Ra) of the hydrophobic stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com