Tab and method for manufacturing same and lithium ion battery comprising the tab

A technology of tabs and tabs, applied to battery electrodes, battery pack components, circuits, etc., can solve problems such as poor adhesion, insufficient toughness, scratches, etc., and achieve improved safety performance and excellent adhesive performance , to avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] This example is used to illustrate the manufacturing method of the tab of the lithium ion battery provided by the present invention.

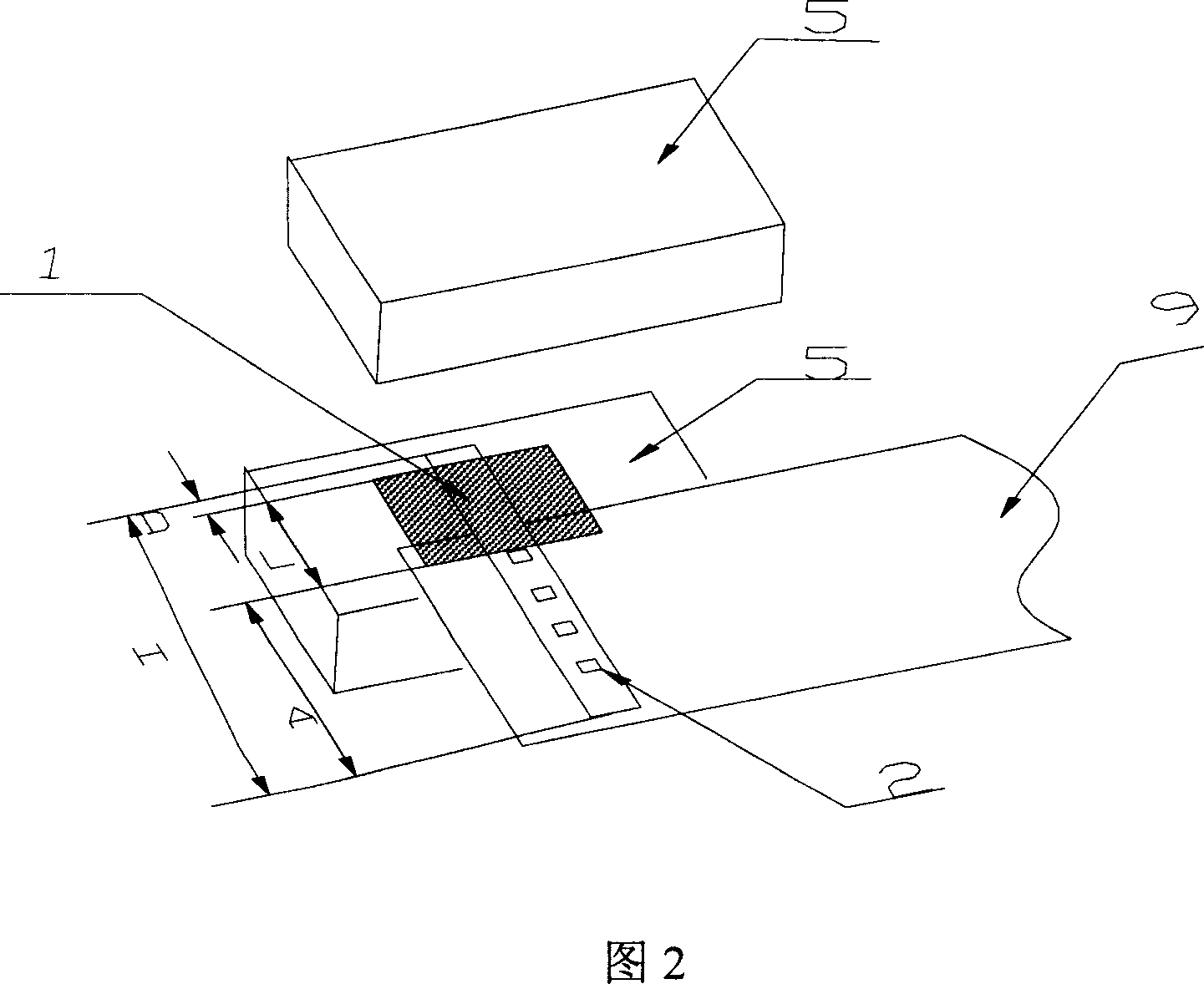

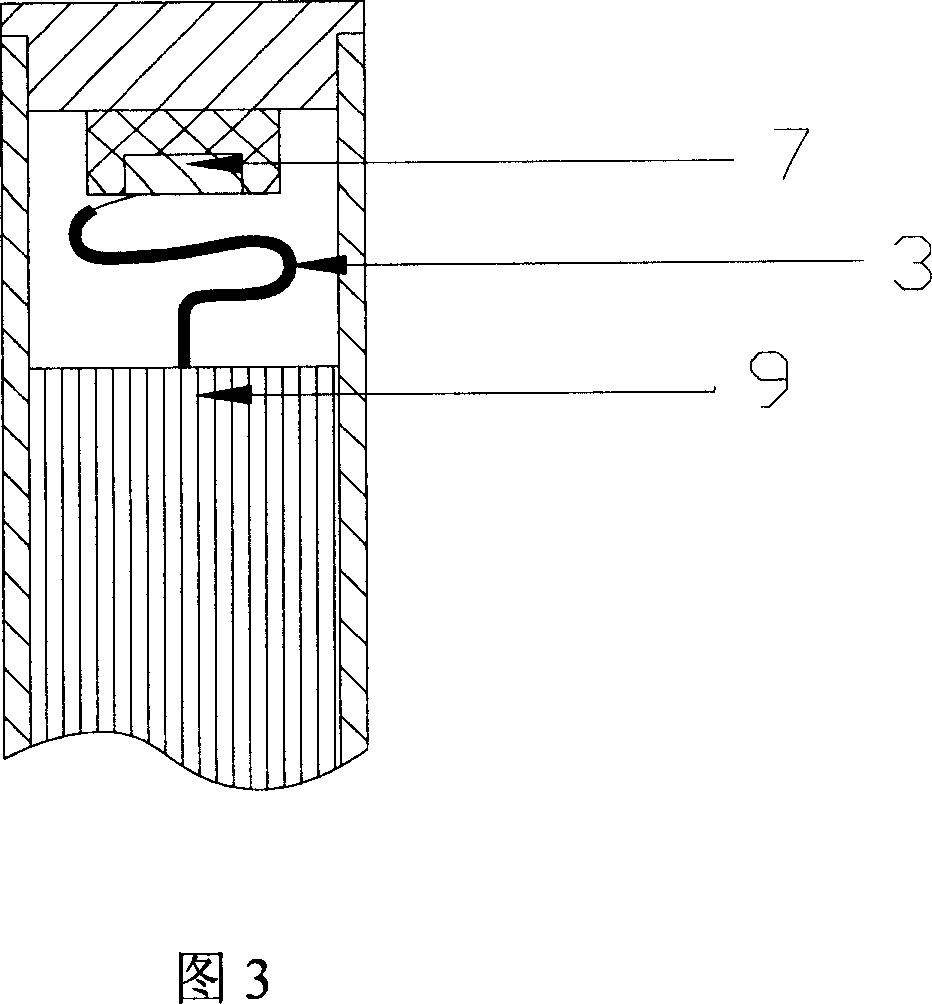

[0037] Adopt the pole piece in comparative example 1, difference is according to the tab manufacturing method provided by the present invention, the width of pole tab 2 as shown in Figure 2 is 3 millimeters, and length H is 24 millimeters, is connected with electrode piece 9 The length A of the connection part is 12 mm, and the length D of the connection part connected with the connection piece 7 of the battery terminal is 2.5 mm. The width of the hot melt adhesive film 1 is 9 mm, and the length is 9.5 mm. Put two such hot-melt adhesive films 1 on the upper and lower sides of the non-connecting part of the tab piece 2, clamp the tab piece 2, and then use the pressurized module 5 at a temperature of 150 degrees Celsius and a pressure of 0.08 MPa. Press the hot-melt adhesive film 1 up and down for 10 seconds, then take out the tab piece 2...

example 2

[0039] This example is used to illustrate the manufacturing method of the tab of the lithium ion battery provided by the present invention.

[0040] According to the method described in Example 1, the hot melt adhesive film 1 is wrapped on the tab piece 2. The difference is that when hot pressing, the extra width of the two sides measured with a millimeter ruler is 3 mm. The hot melt adhesive film 1 is placed outside the heating module 5 . The part of the excess hot-melt adhesive film 1 is not hot-pressed.

[0041] The following examples are used to illustrate the characteristics of the hot melt adhesive film of the present invention.

example 3

[0043]The tabs hot-pressed with hot-melt adhesive film and the tabs wrapped in adhesive tape prepared in Example 1 and Comparative Example 1 were respectively soaked in the same lithium-ion battery electrolyte. After sealing, place them at room temperature and 50 degrees Celsius respectively, observe their corrosion resistance and shedding after 10 months, and compare the differences between them. Wherein, the electrolyte is a commonly used electrolyte in the field, which is a mixed solution of electrolyte lithium salt and non-aqueous solvent. Among them, the electrolyte lithium salt is selected from lithium hexafluorophosphate (LiPF6), lithium hexafluoroarsenate, lithium halide, lithium chloroaluminate and lithium fluoroalkyl sulfonate; the organic solvent is a mixed solution of chain ester and cyclic ester, wherein the chain The esters are dimethyl carbonate (DMC), diethyl carbonate (DEC), and the cyclic esters are ethylene carbonate (EC), propylene carbonate (PC), vinylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com