Oscillatory auger hole and dredging device

A technology of vibrating screw and auger rod, which is applied to mechanically driven excavators/dredgers, drill bits, drilling equipment, etc., can solve problems such as hole wall collapse, reduce friction resistance, reduce vibration mass and amplitude Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

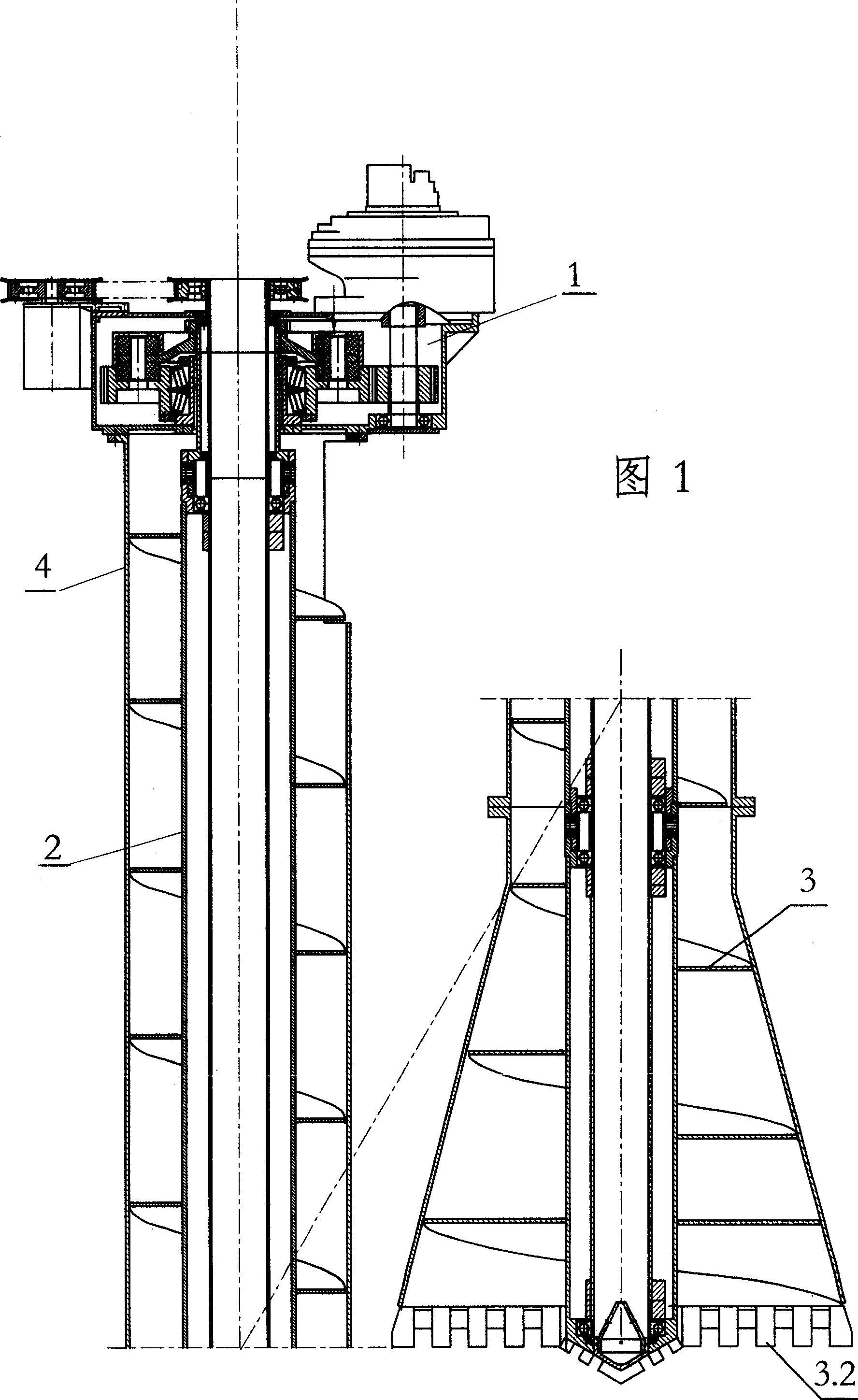

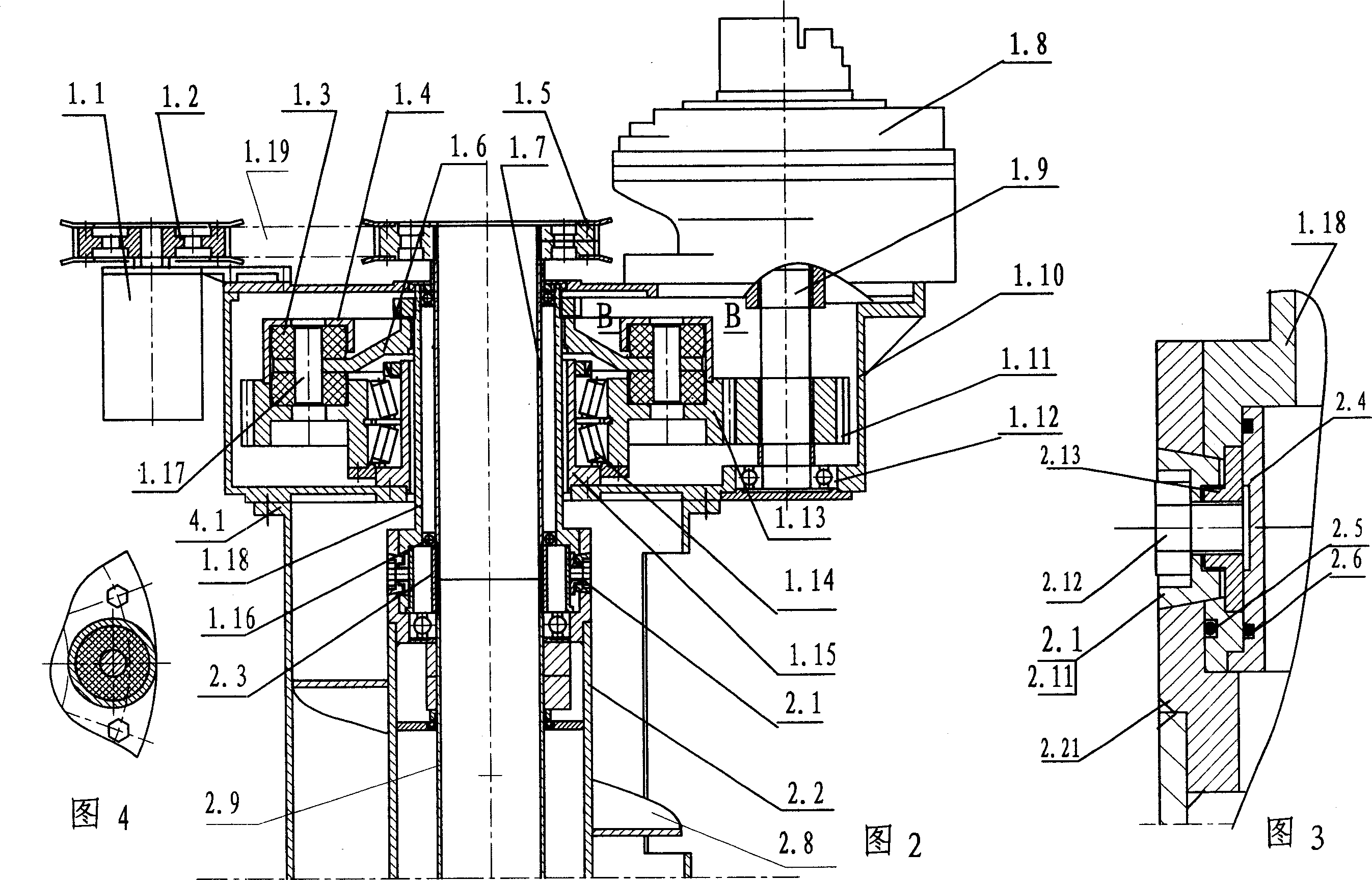

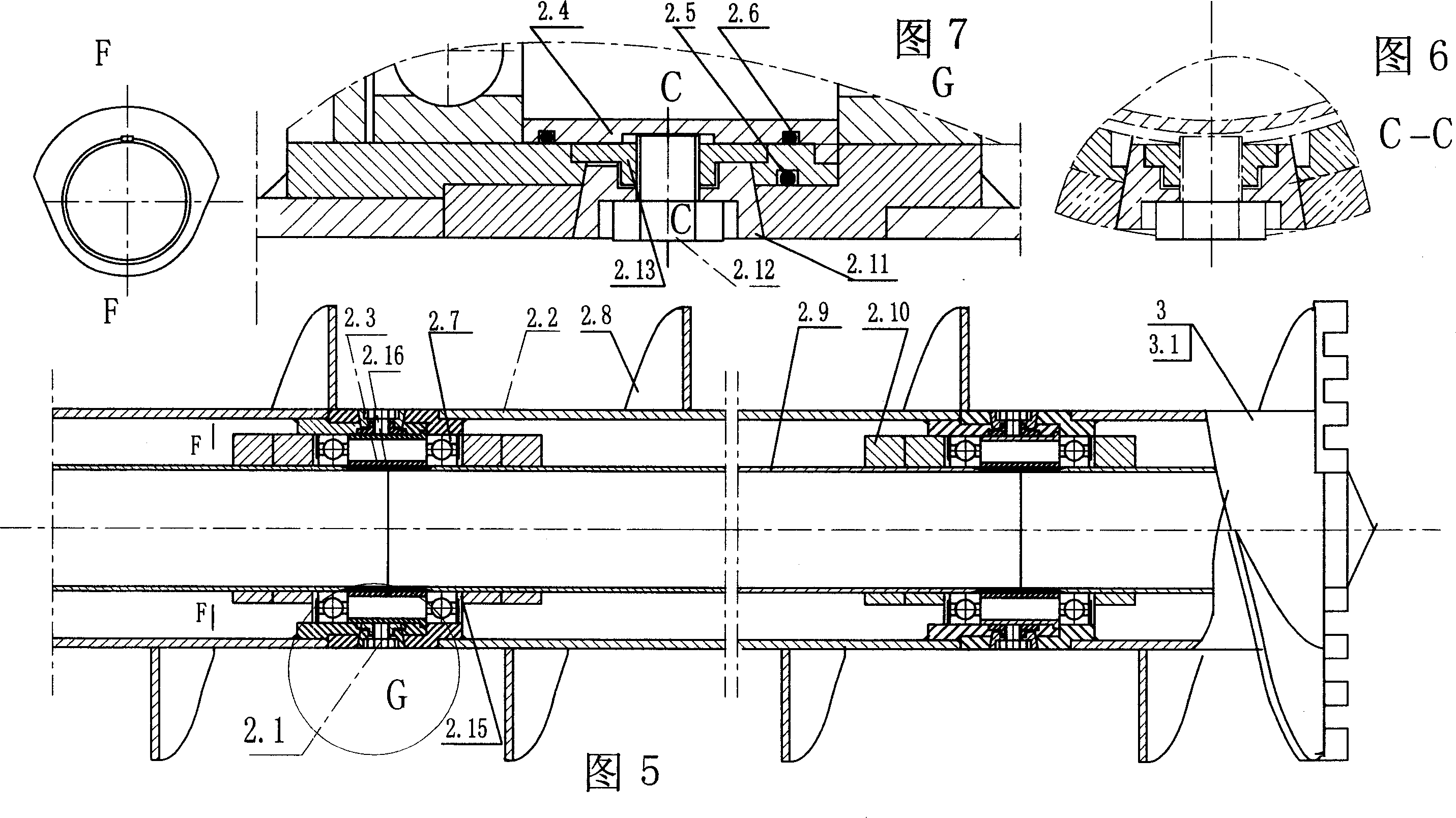

[0050] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the vibrating helical drilling and dredging device of the present invention is composed of a power head 1, an auger rod 2, a central conduit 2.9, a drill bit 3 and a casing 4; the power head 1 Located on the top of the auger rod 2, a low-speed hydraulic motor 1.8 is located on the upper part of the power head case 1.10, the output shaft of the low-speed hydraulic motor extends downward into the case, the axis is parallel to the center line of the auger rod 2, and offset by a distance, the low-speed The hydraulic motor 1.8 is connected with the pinion 1.11 through the spline shaft 1.9, the upper end of the spline shaft 1.9 is connected with the output shaft of the low-speed hydraulic motor, the lower end is installed in the power head chassis 1.10 with the ball bearing 1.12, the pinion 1.11 meshes with the large gear 1.13, and the large The gear 1.13 is installed on the chassis mandrel 1.15 with a pair of conical thrust beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com