Method of preparing potable water

a technology of potable water and slurry, which is applied in the nature of treatment water, water/sewage treatment by oxidation, and other chemical processes, can solve the problems of unsuitable water for human consumption, numerous chlorination disinfection by-products, and contaminant present in many surface water sources, so as to facilitate the transport of slurry, increase the viscosity of slurry, and inhibit the ability of carbon to clump together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

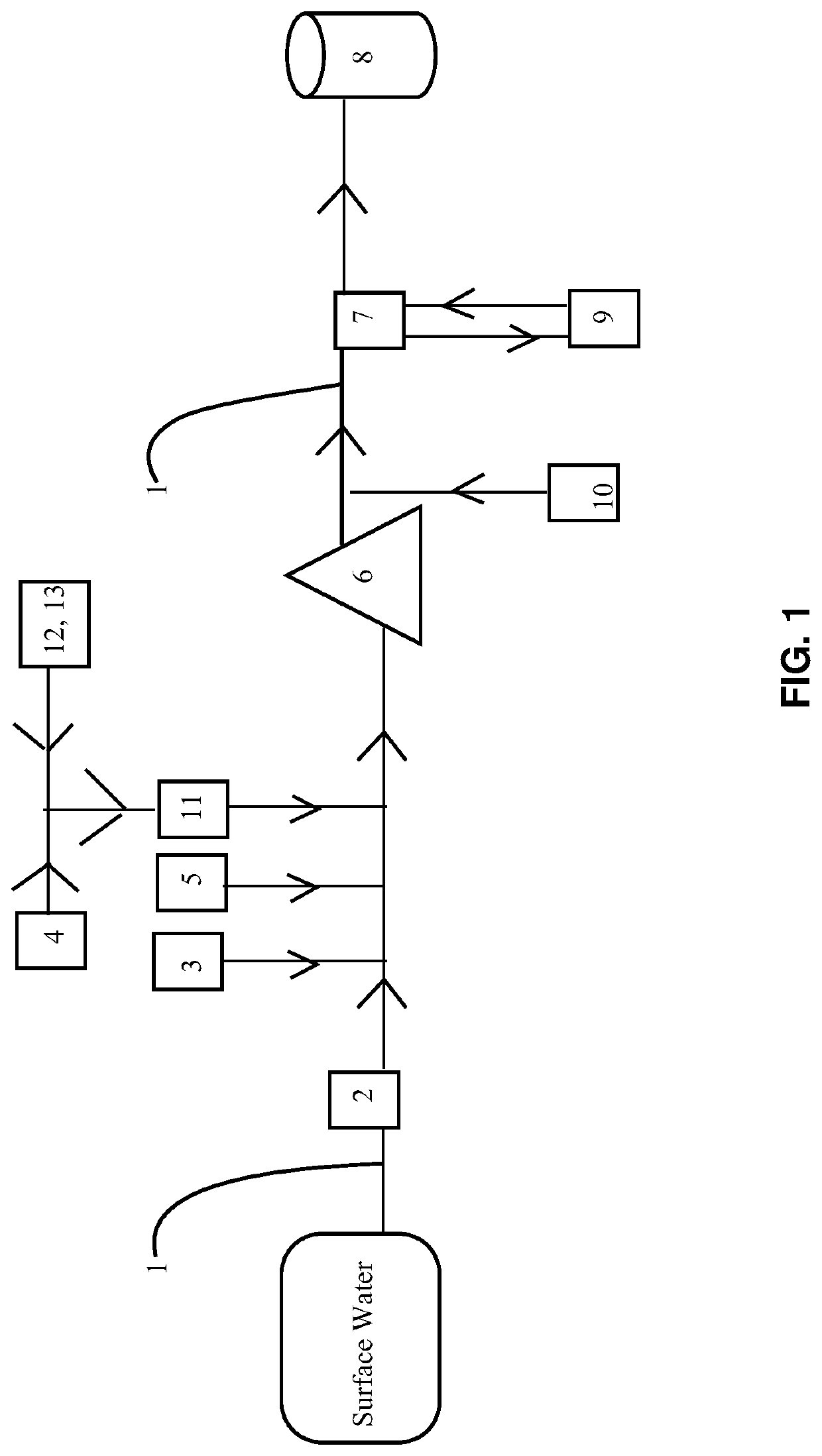

Method used

Image

Examples

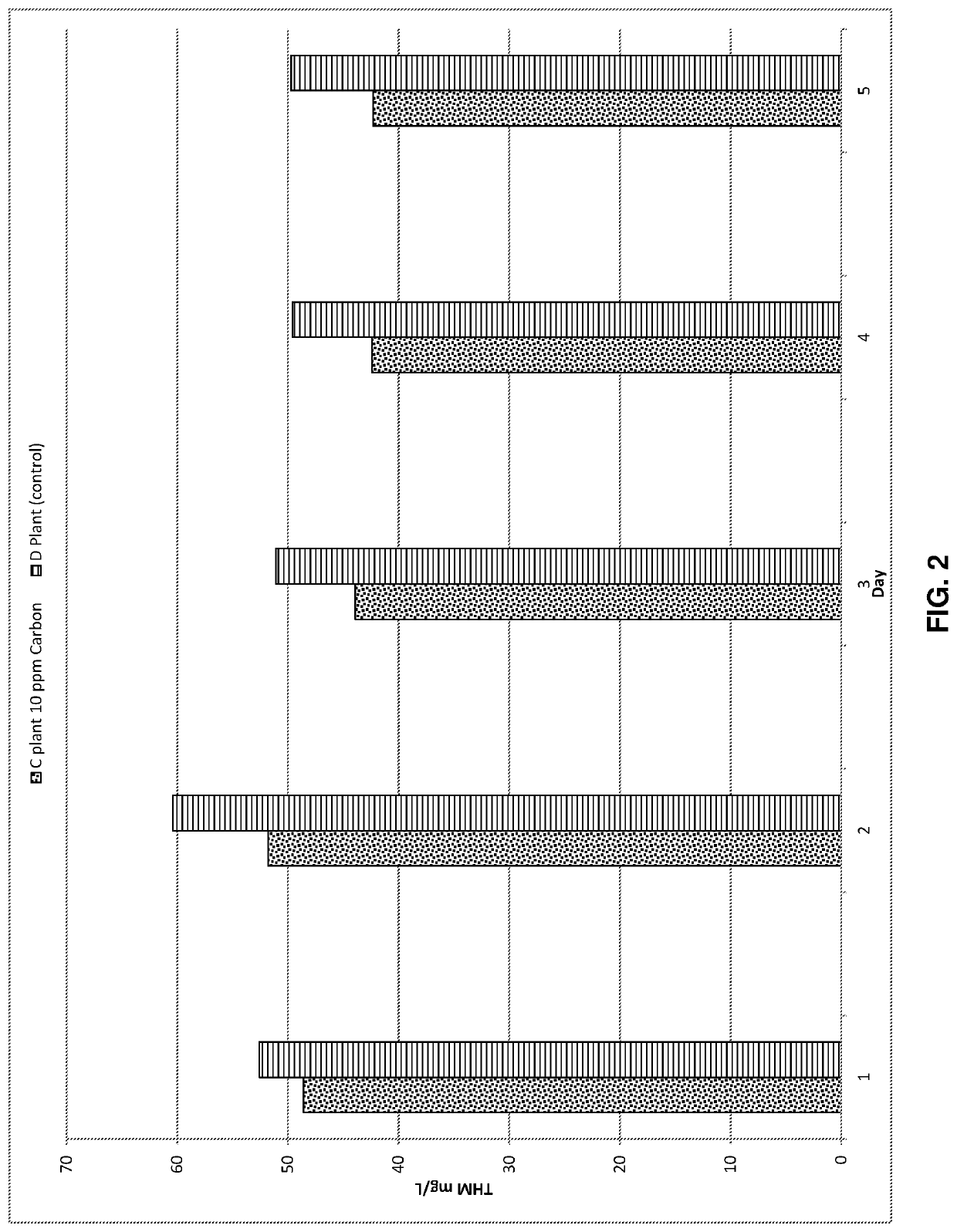

example 1

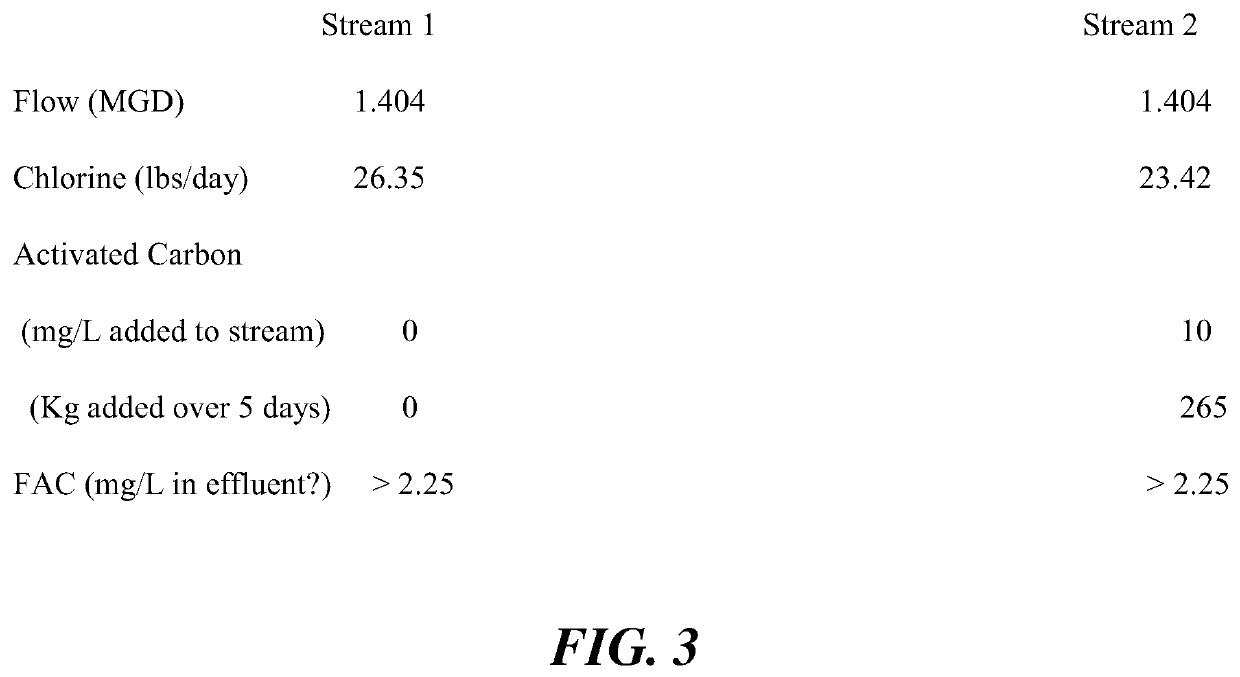

[0080]A water treatment plant with parallel water streams was identified. This plant had two separate incoming streams with substantially identical characteristics. This allowed one to be tested and the other to be used as a control. Each stream was screened for solids. “Before” samples were taken from each stream post-screening. An activated carbon slurry was then added to the test stream. The activated carbon slurry had a carbon concentration of 250 gm / liter. The activated carbon slurry was added at a rate sufficient to create a carbon concentration of 10 mg per liter in the stream. This was slightly more than about ⅓ of a liter of slurry added per minute to a stream flowing at about 9,100 liters per minute. Over five days, approximately 265 Kg carbon were added to the stream.

[0081]The slurry was formed as described above. In addition to water and activated carbon, the slurry included about 1.0 percent by weight Superfloc™ N-300 (7000 LMW) low molecular weight polyacrylamide non-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com