Bulk single crystal gallium nitride and method of making same

a gallium nitride and single crystal technology, applied in envelope/bag making machinery, paper/cardboard containers, applications, etc., can solve the problems of difficult single crystal growth of alloys, difficult production of gan, and difficulty in growing high-quality bulk single crystals, and achieve the effect of improving the final product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

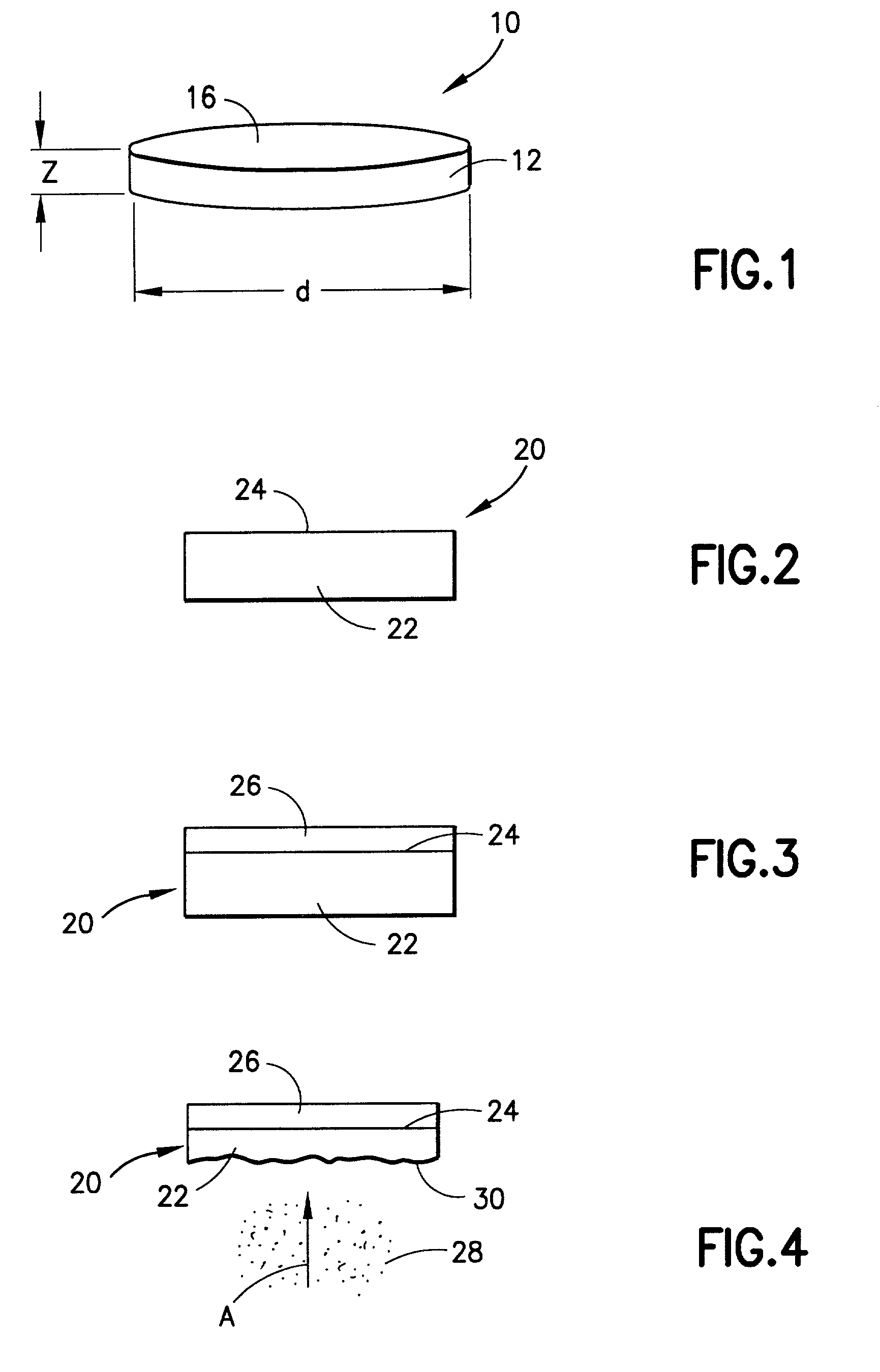

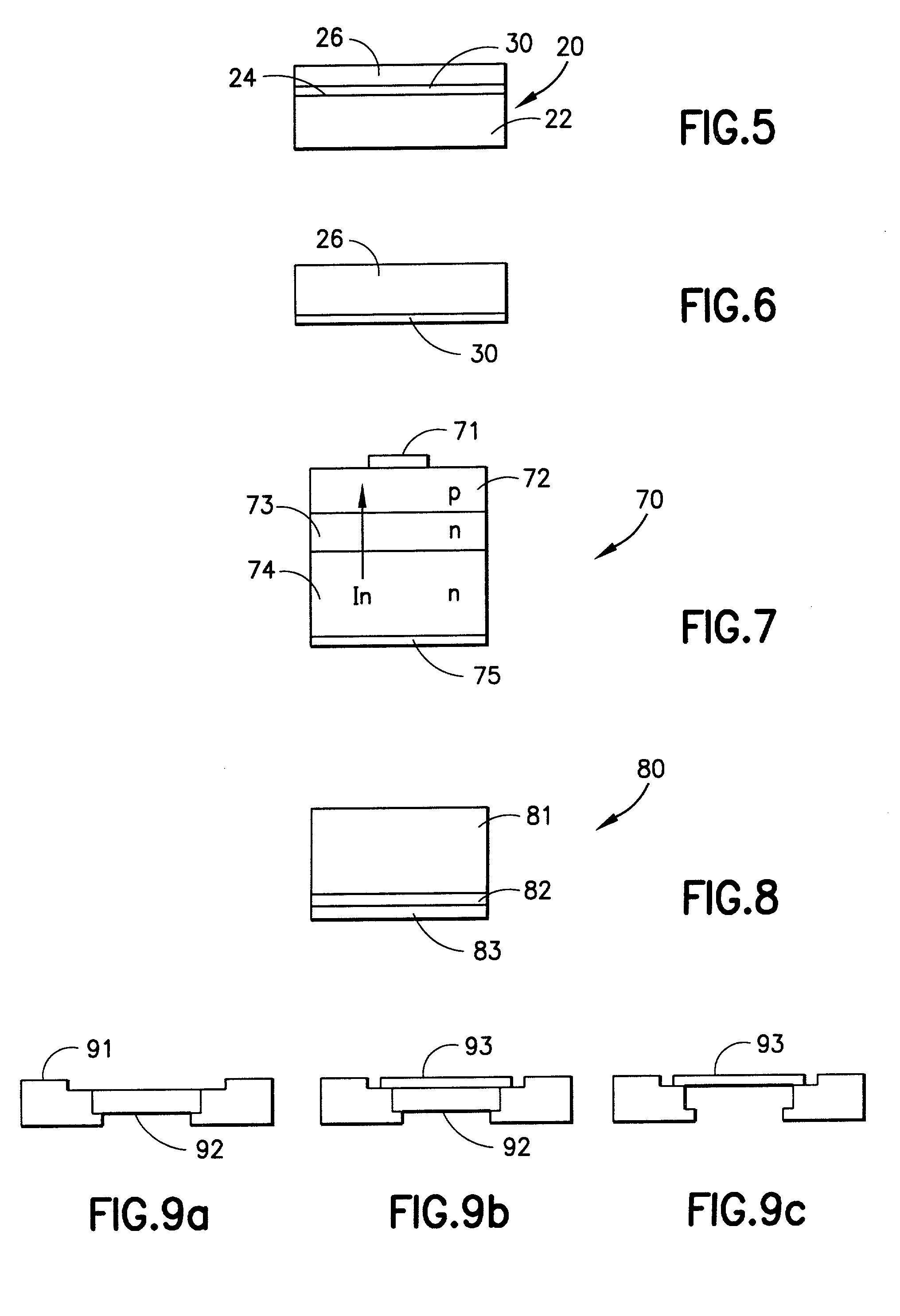

[0037] The present invention is based on the discovery that single crystal M*N articles of a self-supporting structural character can be readily formed by the deposition of single crystal M*N on a substrate epitaxially compatible with the single crystal M*N, followed by in-situ removal of the sacrificial substrate at the growth temperature. The substrate is removed by etching it away from the single crystal M*N, at the M*N growth temperature or at a temperature in proximity to the growth temperature, to yield the single crystal M*N as a product article.

[0038] Since no M*N substrates currently (before the making of the present invention) exist, growth of these compounds must initially take place heteroepitaxially, for example GaN on silicon. Two types of defects arise as a result of heteroepitaxial growth. The first is dislocations due to the lattice mismatch between the M*N layer and the substrate. The typical substrate for GaN is sapphire, which has a 13.8% lattice mismatch to GaN....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com