Liquid crystal display device and method of manufacturing the same

a liquid crystal display device and active matrix technology, applied in the direction of identification means, instruments, optics, etc., can solve the problems of small visibility angle, adversely affecting the color filter layer, and small visibility angle of tn type liquid crystal display devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

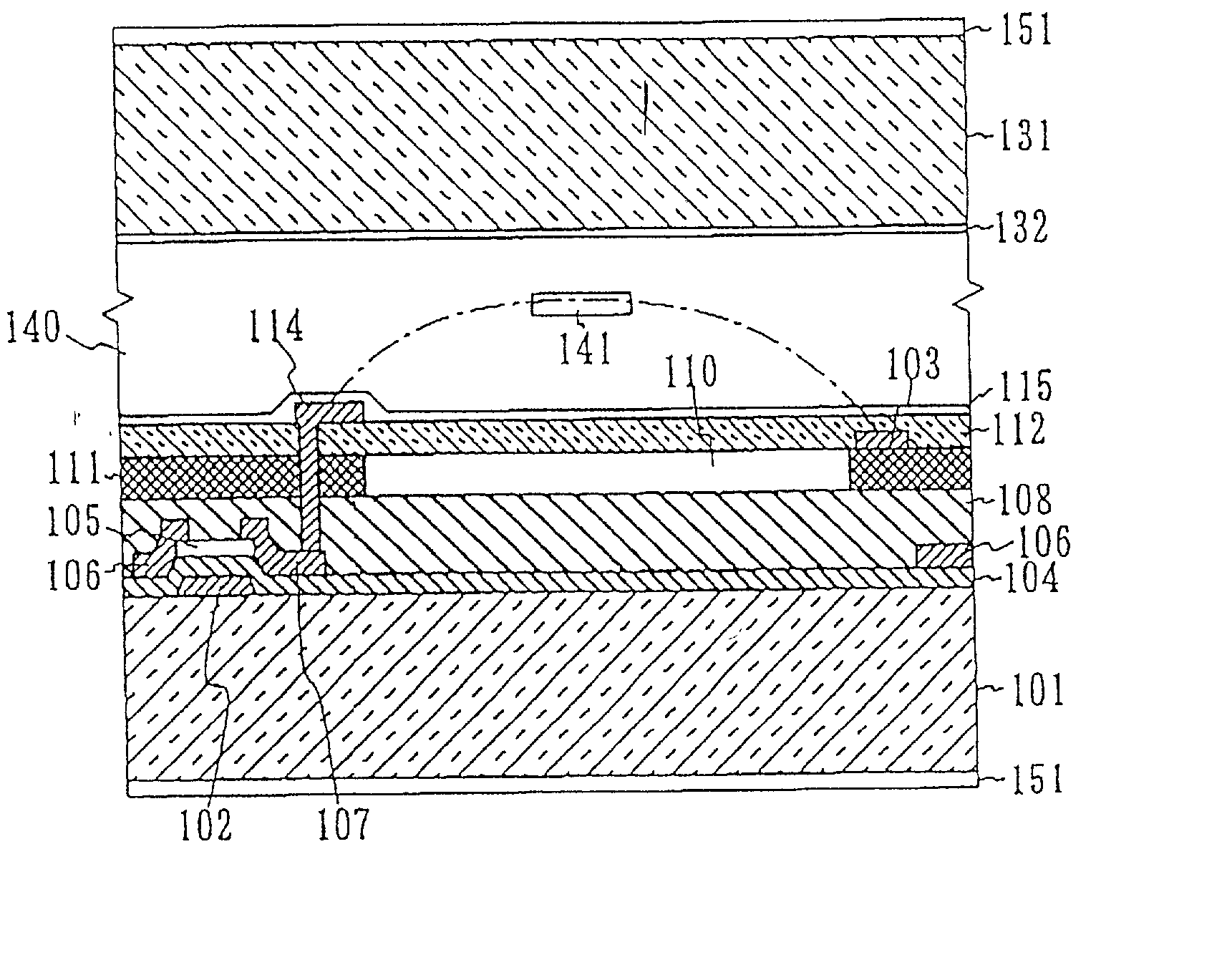

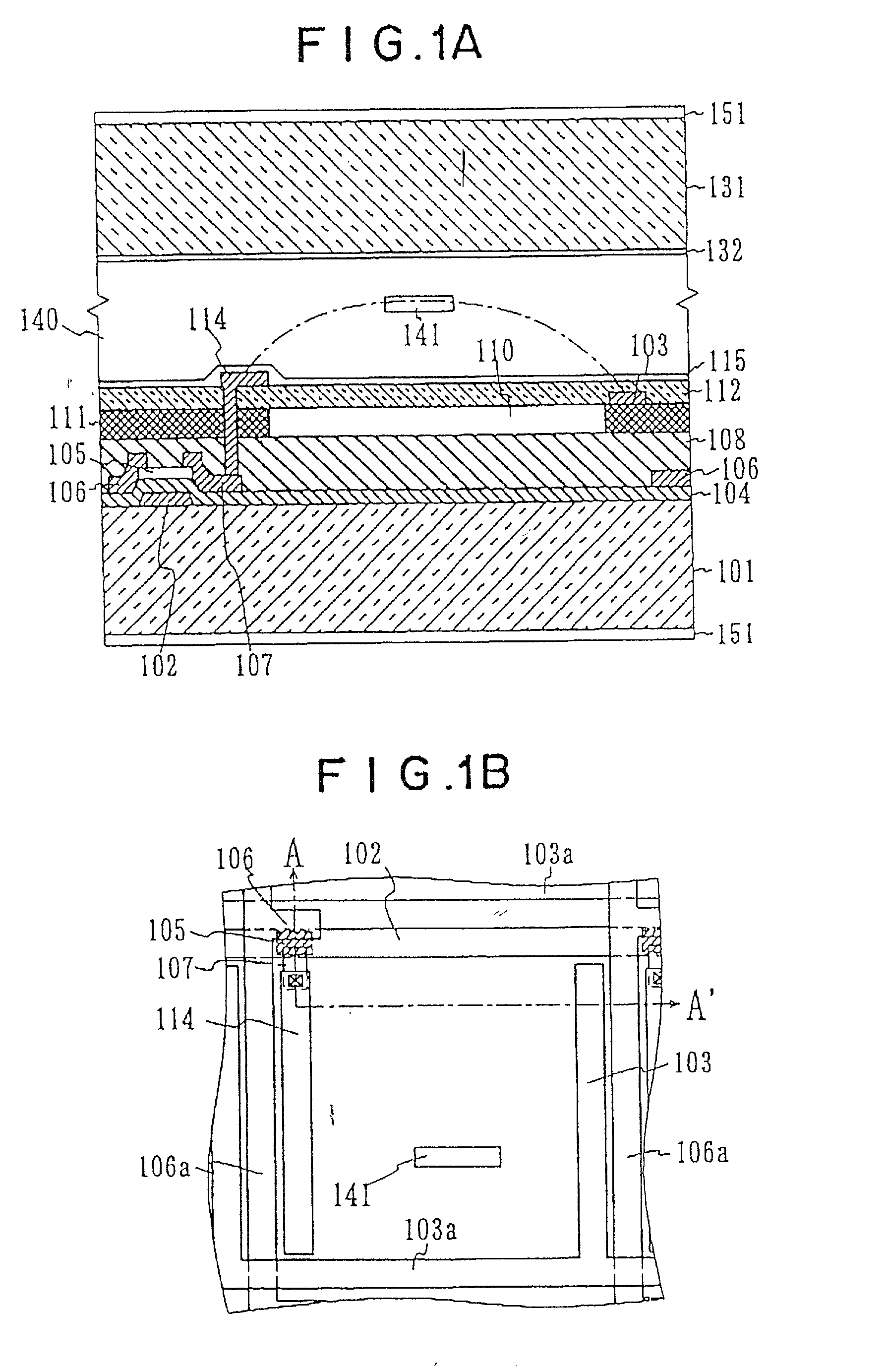

[0151] [First Embodiment]

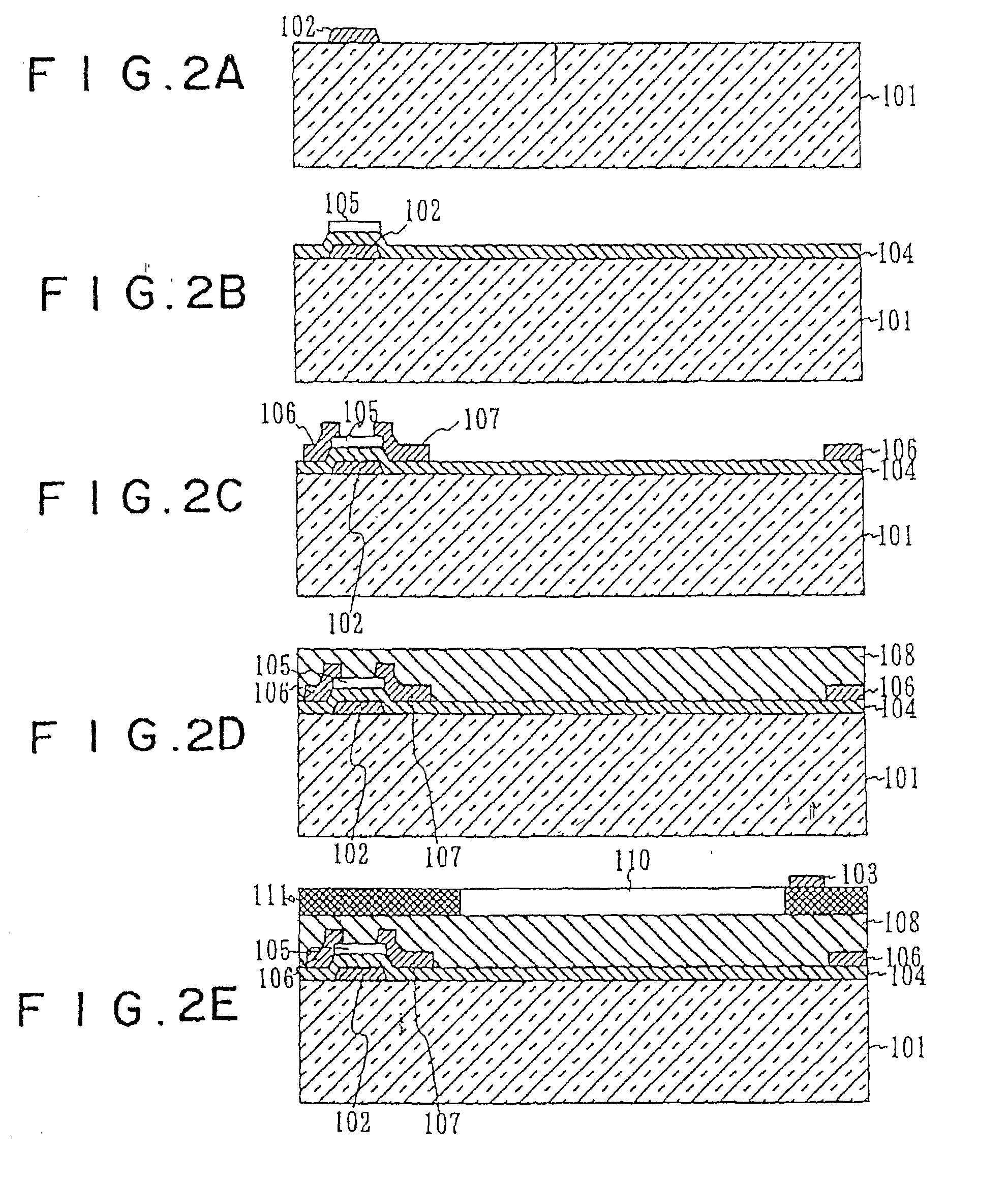

[0152] A substrate having an array of amorphous silicon thin film transistors (TFT) was formed on a glass substrate by repeating both of a film forming process and a lithography process. The TFT array comprises a gate--chrome layer, a silicon nitride--gate insulating layer, an amorphous silicon-semiconductor layer, a drain / source--molybdenum layer which were arranged from the substrate side in this order (see FIG. 2C). Thereafter, a protection film was formed of silicon nitride so as to cover the above layers.

[0153] Subsequently, for example a color filter layer of green was coated on the protection layer, heated and dried and formed by photolithography. The same process was repeated to form red, blue color filter layers, thereby forming a color filter layer. A light shielding portion was formed by using resin containing black pigment in the same manner. Thereafter, a common electrode was formed of chrome, and then an overcoat layer of acrylic resin was coat...

second embodiment

[0159] (Second Embodiment)

[0160] As in the case of the first embodiment, an array of amorphous silicon thin film transistors (TFT) was formed by repeating both the film forming process and the lithography process. TFT comprised a gate--chrome layer, a silicon nitride--gate insulating layer, a amorphous silicon--semiconductor layer and a drain / source--molybdenum layer which were arranged from the substrate side in this order as in the case of the first embodiment.

[0161] A protection film of silicon nitride was formed so as to cover the above layers, and red, blue and green color filter layers were formed in the same manner as the first embodiment. After a common electrode was formed of chrome, an overcoat layer of acrylic resin was coated and heated for one hour at 200.degree. C.

[0162] Subsequently, a through hole was formed so as to extend to the source electrode, and a pixel electrode is formed by using ITO SE1211 produced by Nissan Chemical Company was coated as a vertical orienta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| areas | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com