Inorganic compound-coated pigments and cosmetics using the same

a technology of compound coating and pigment, applied in the direction of material nanotechnology, chemistry apparatus and processes, make-up, etc., can solve the problems of cosmetics not being able to cover human skin with adequate stability for a long time, the ability of masking to be lower, and the cosmetics not being able to achieve adequate stability in us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0041] Embodiment 1

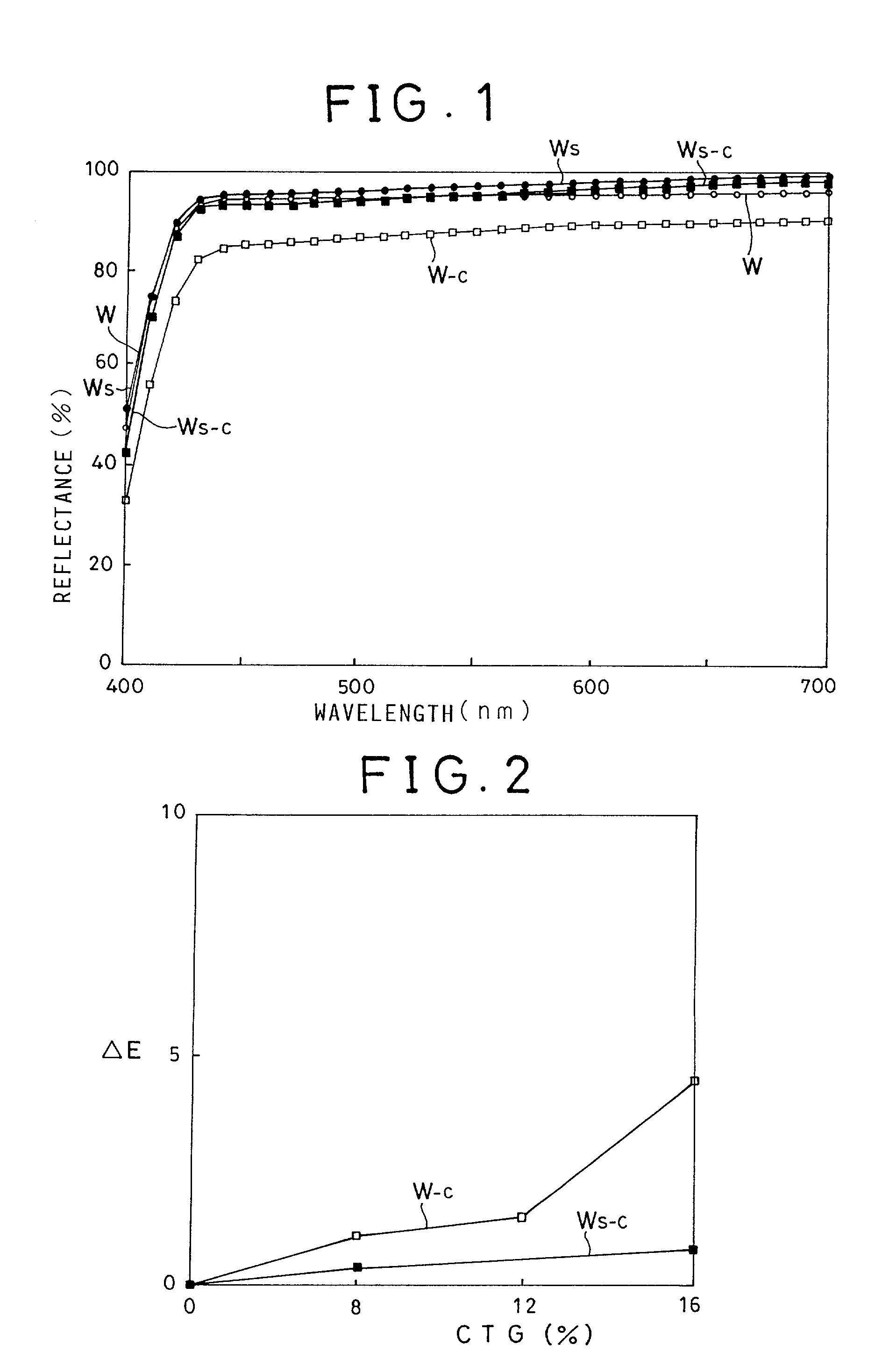

[0042] 90 g white pigments (W) made of titanium oxide and having an average particle diameter of 250 nm was mixed in one litter of ethanol to prepare a dispersion. This dispersion was heated to 45.degree. C. and 28% aqueous annomia was added to adjust pH to 9.5 or more, and then tetraethoxysilane with the weight equivalent to 10 g of SiO.sub.2 and 110 g of 28% aqueous ammonia was added to the dispersion while preserving the conditions described above. After addition of the compounds described above, the dispersion was further agitated for additional two hours, and then filtered, washed, and dried under the temperature of 110.degree. C., and further sintered under the temperature of 600.degree. C., and silica-coated titanium oxide white pigments (Ws) were obtained. The white pigments were observed with an electronic microscope, and it was found that the particles were not aggregated and the particle shapes and diameters before and after coating with silica were sub...

embodiment 2

[0050] Embodiment 2

[0051] Indian red pigments coated with silica (Rs) was obtained by the same method as that described above excluding only the point that Indian redpigments (R) made from needle-shaped particles each having an average length of 500 nm and an average diameter of 100 nm was used in place of the titanium oxide used in Embodiment 1. Observation of the red pigments with an electronic microscope showed that the particles had not be aggregated and particles shapes and diameters before and after coating with silica were substantially identical.

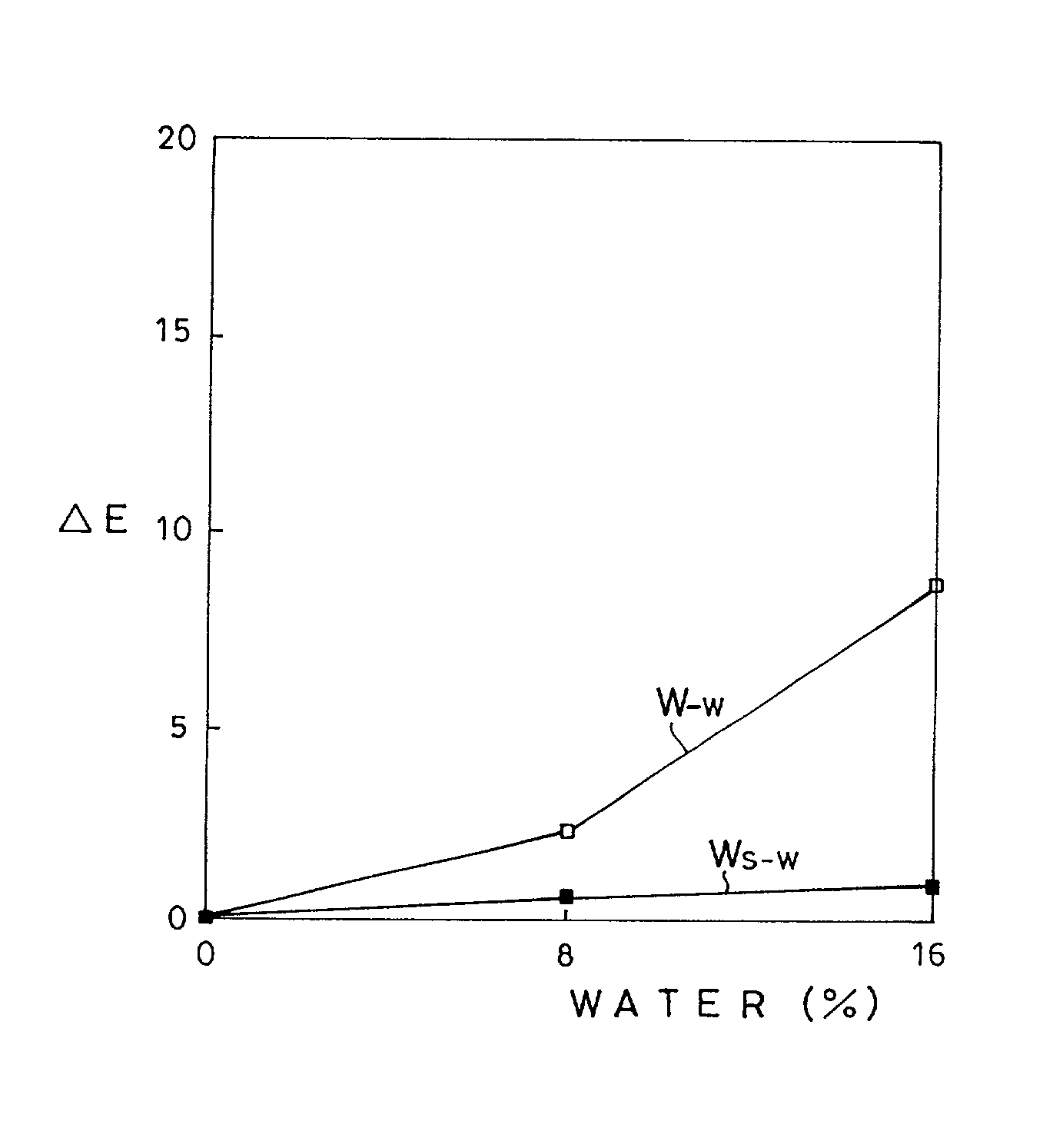

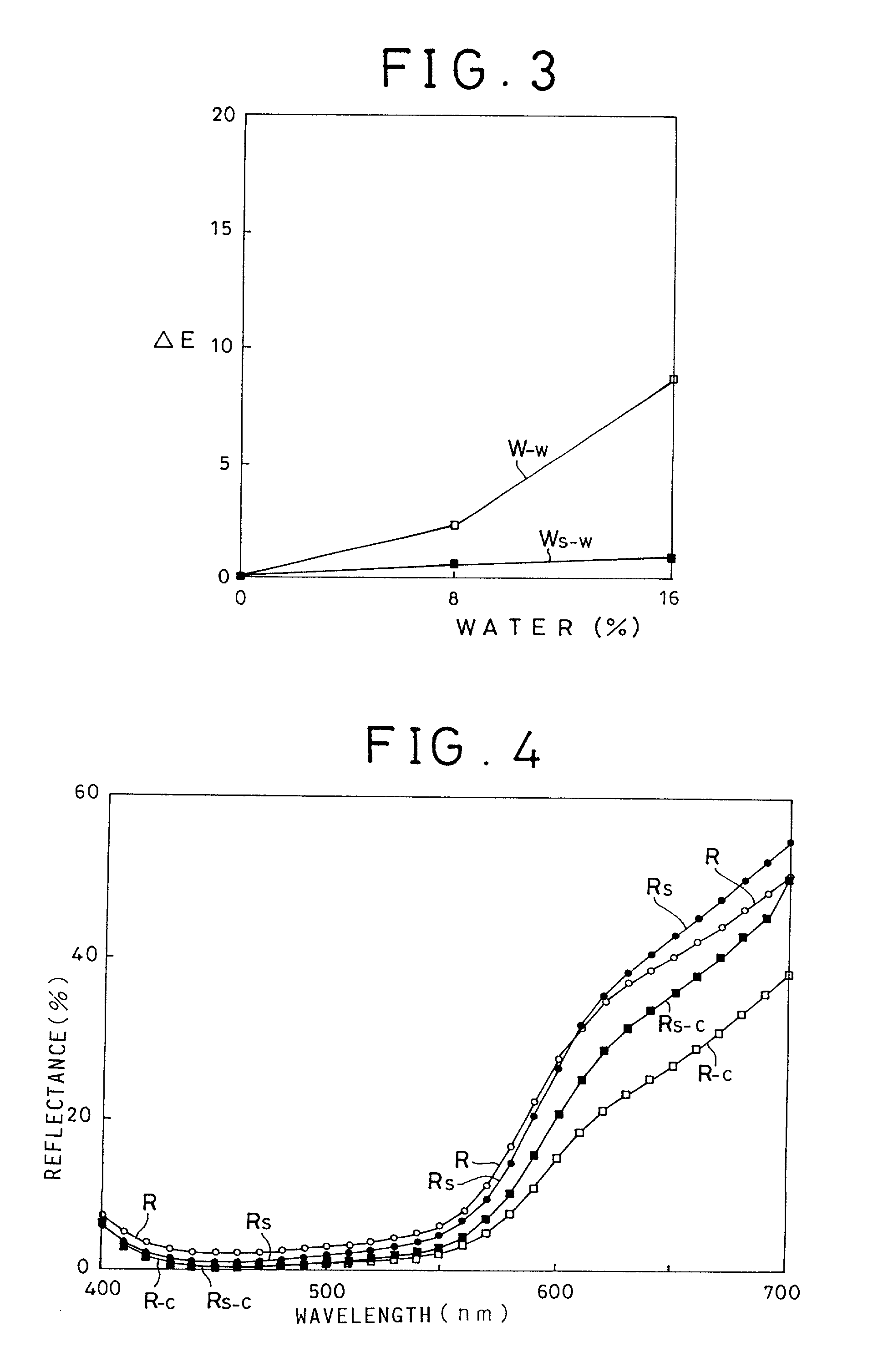

[0052] Changes of a color tone for the resultant red pigments coated with silica (Rs) and red pigments non-coated with silica (R) were measured like in Embodiment 1. A result of the measurement is shown in FIG. 4 to FIG. 6 and in Table 2.

2 TABLE 2 Color difference (.DELTA.E) CTG 16 wt % Water 16 wt % Non-coated red pigments (R): 11 11 Silica-coated red pigments (Rs): 4.9 3.3 Decrease rate (%) of .DELTA.E: 55 70

[0053] Like in a case o...

embodiment 3

[0054] Embodiment 3

[0055] Yellow iron oxide pigments coated with silica (Ys) was obtained by the same method as that described above excluding only the point that yellow iron oxide pigments (Y) made from needle-shaped particles each having an average length of 500 nm and an average diameter of 100 nm was used in place of the titanium oxide used in Embodiment 1. Observation of the yellow pigments with an electronic microscope showed that the particles had not be aggregated and particles shapes and diameters before and after coating with silica were substantially identical.

[0056] Changes in a color tone of the resultant yellow pigments coated with silica (Ys) and yellow pigments non-coated with silica (Y) were measured like in Embodiment 1. A result of the measurement is shown in FIG. 7 to FIG. 9 and in Table 3.

3 TABLE 3 Color difference (.DELTA.E) CTG 16 wt % Water 16 wt % Non-coated yellow pigments (Y): 17 15 Silica-coated yellow pigments (Ys): 4.1 4.4 Decrease rate (%) of .DELTA.E:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com