Method of manufacturing a semiconductor device

a manufacturing method and semiconductor technology, applied in semiconductor devices, instruments, electrical devices, etc., can solve problems such as the variation of the taper angle of the resist pattern side wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

]

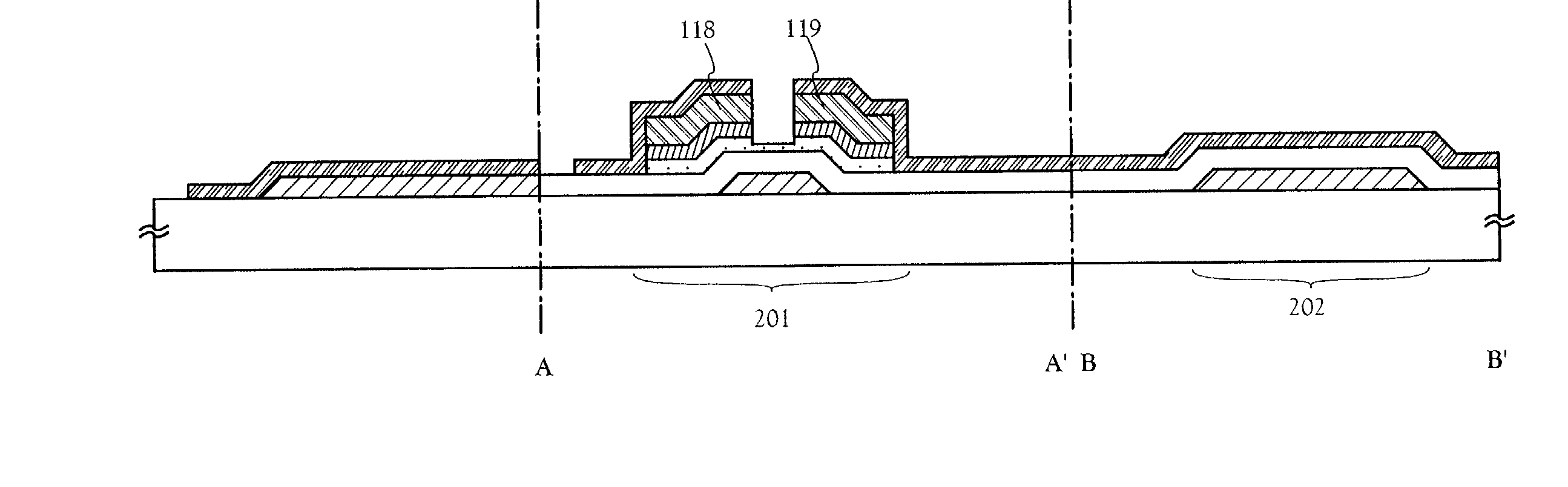

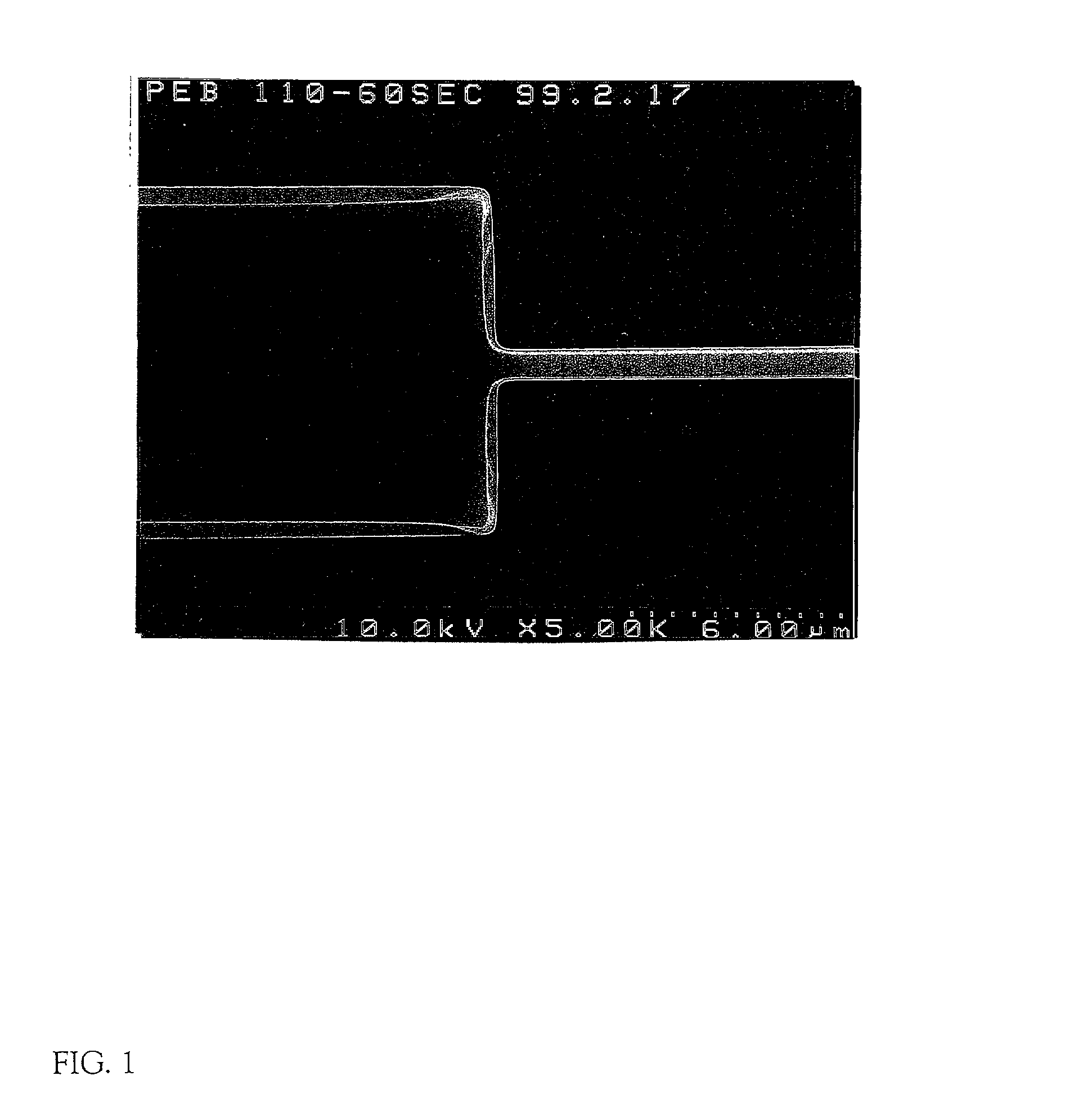

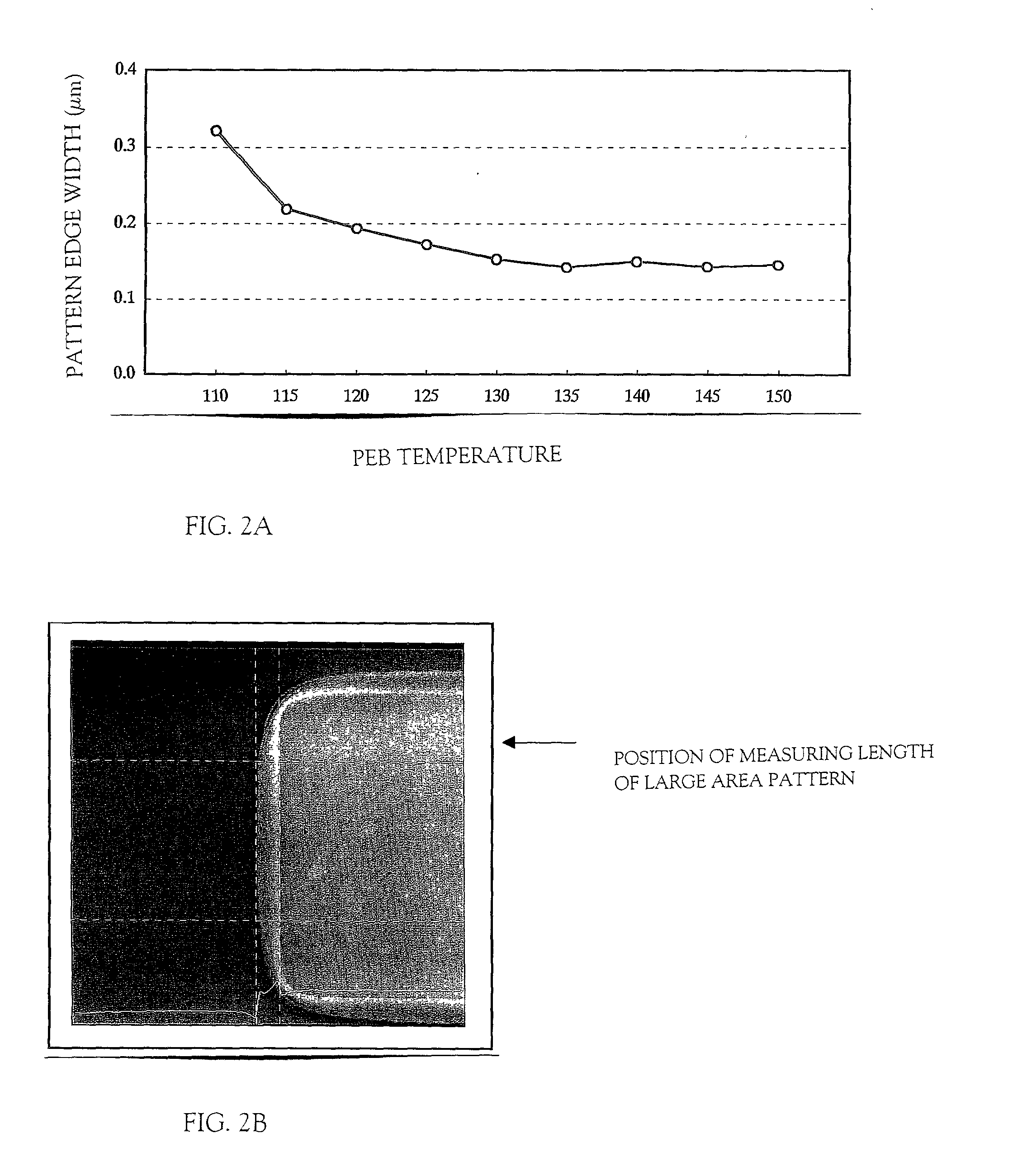

[0051] The present invention relates to a structure of an inverted stagger type TFT having a bottom gate structure and a method of manufacturing the same, characterized in that, by restricting a bake condition between a pre-bake temperature or PEB temperature and a post-bake temperature in a photolithography step, taper angles of various dimensions of resist patterns are accurately controlled, as a result, accurately controlling shapes of various dimensions of etching patterns. Specific embodiment mode of the structure of the inverted stagger type TFT and the method of manufacturing the same in accordance with the present invention are described below with reference to FIGS. 4A-4D, FIGS. 5A-5B and FIG. 6.

[0052] It is to be noted that FIGS. 4A-4D and FIGS. 5A-5B are cross-sectional views illustrating a manufacturing steps of an active matrix liquid crystal display device, and FIG. 6 is a top view illustrating configuration of a pixel region in the active matrix liquid crystal displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com