Holding material for catalytic converter and method for producing the same

a technology of catalytic converter and holding material, which is applied in the direction of machines/engines, mechanical equipment, separation processes, etc., can solve the problems of alumina fiber mat, surface pressure is slightly reduced in comparison with other fiber mats in equal density, and the temperature of not less than 600.degree. c of ceramic fiber ma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Into water, 97 parts by weight of alumina fiber of low crystallinity containing 96% by weight of Al.sub.2O.sub.3 (and SiO.sub.2 as a residual component) and having a fiber size of about 4 .mu.m and a fiber length of about 3 mm, and 5 parts by weight of an organic binder (acrylic emulsion) were dispersed to prepare an alumina fiber-containing aqueous slurry. On the other hand, 97 parts by weight of mullite fiber of low crystallinity containing 80% by weight of Al.sub.2O.sub.3 (and SiO.sub.2 as a residual component) and having a fiber size of about 4 .mu.m and a fiber length of about 3 mm, and 3 parts by weight of an organic binder (acrylic emulsion) were dispersed into water to prepare a mullite fiber-containing aqueous slurry.

[0037] First, the alumina fiber-containing aqueous slurry was molded by suction dehydration and dried to produce an alumina fiber mat having grammage (areal density) of 400 g / m.sup.2. Then, the mullite fiber-containing aqueous slurry was applied on one s...

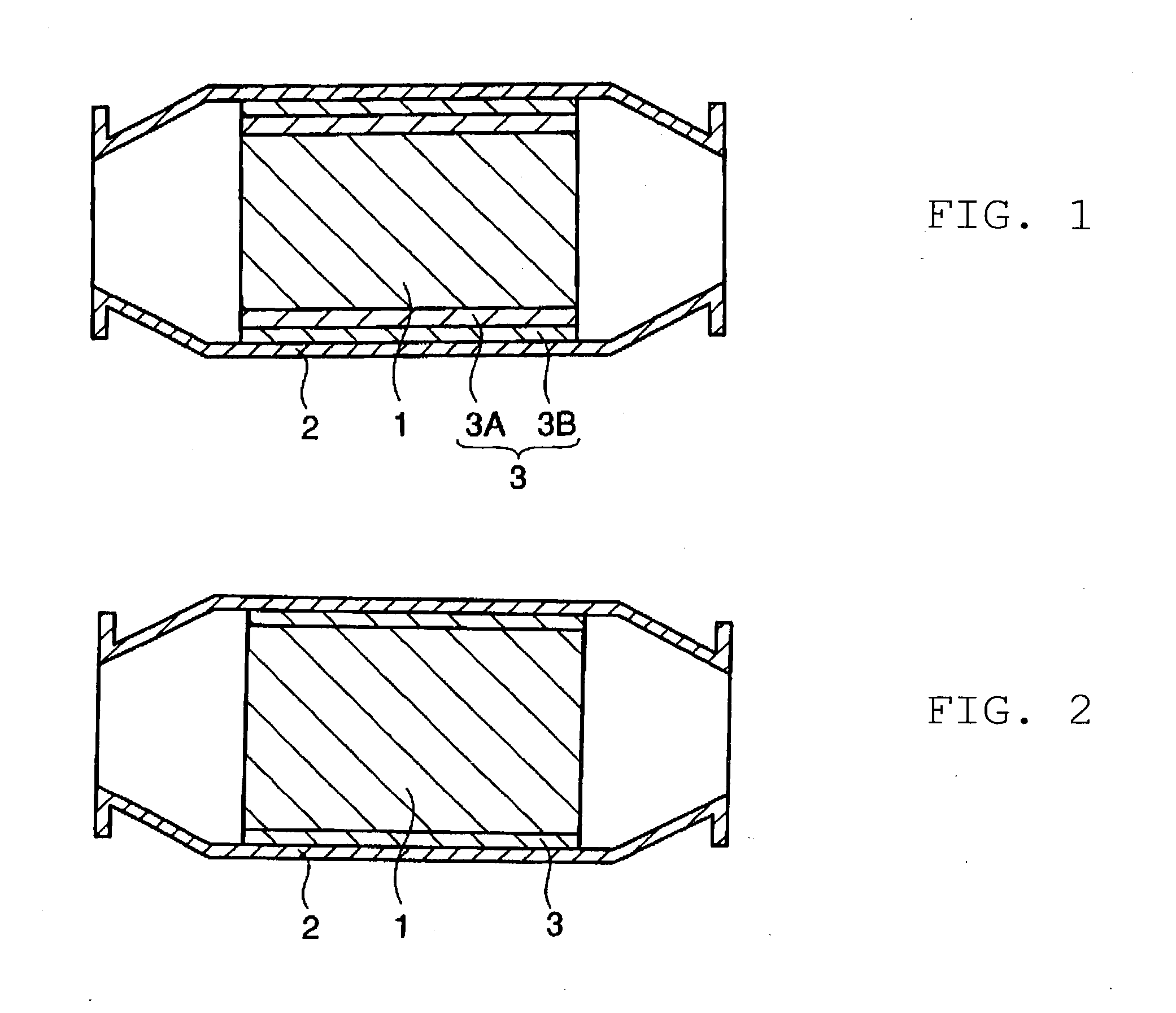

second embodiment

[0045] Second Embodiment

[0046] FIG. 2 is a sectional view schematically showing a catalytic converter provided with a holding material according to a second embodiment of the invention. The configuration of the catalytic converter is the same as that of a related-art catalytic converter except that the holding material 3 according to the invention is constituted by a mixture of alumina fiber and mullite fiber.

[0047] The holding material 3 can be shaped like a flat mat. When the holding material 3 is molded into a shape according to the contour shape (e.g., cylindrical shape in FIG. 2) of a catalyst carrier 1, the holding material 3 can be directly mounted on the catalyst carrier 1 to facilitate production of the catalytic converter.

[0048] Materials suitably selected from known materials heretofore used in a holding material can be used as the alumina fiber and the mullite fiber. The material preferably used as the alumina fiber is fiber containing 90% by weight or more of Al.sub.2O....

example of second embodiment

[0061] The invention will be described below more specifically in connection with the following Examples and Comparative Examples but the invention is not limited thereto at all.

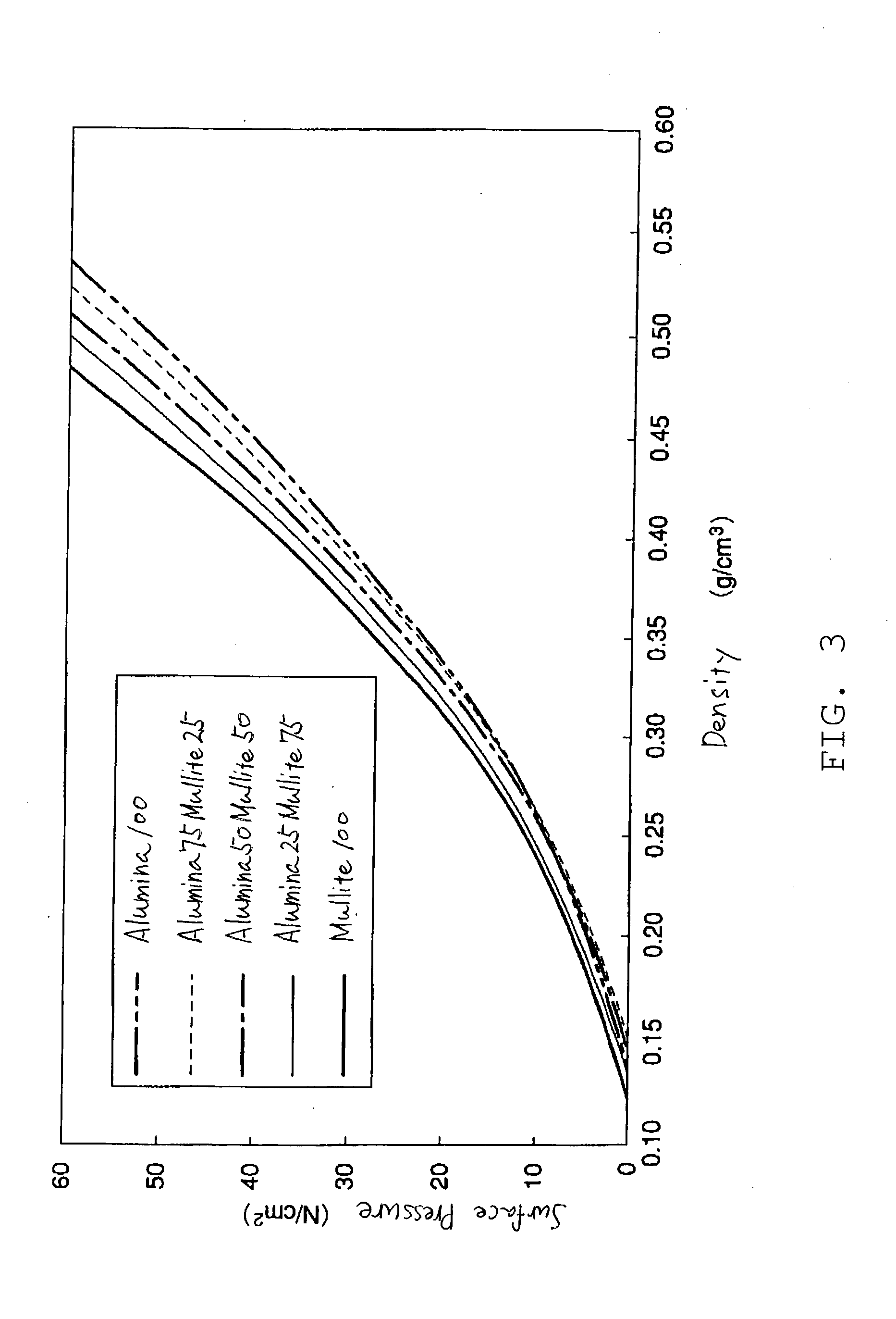

[0062] Alumina fiber of low crystallinity containing 96% by weight of Al.sub.2O.sub.3 (and SiO.sub.2 as a residual component) and having a mean fiber size of about 3 .mu.m and a wet volume of 800 cc / 5 g was mixed with mullite fiber of low crystallinity containing 80% by weight of Al.sub.2O.sub.3 (and SiO.sub.2 as a residual component) and having a mean fiber size of about 4 .mu.m and a wet volume of 800 cc / 5 g while the mixture ratio (weight ratio) of alumina fiber to mullite fiber was changed variously to (1) 100% of alumina fiber, (2) 75% of alumina fiber and 25% of mullite fiber, (3) 50% of alumina fiber and 50% of mullite fiber, (4) 25% of alumina fiber and 75% of mullite fiber, and (5) 100% of mullite fiber. With respect to 100 parts by weight of each of the thus obtained mixtures, 8 parts, by weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Surface pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com