Apparatus and method for plasma enhanced monolayer processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

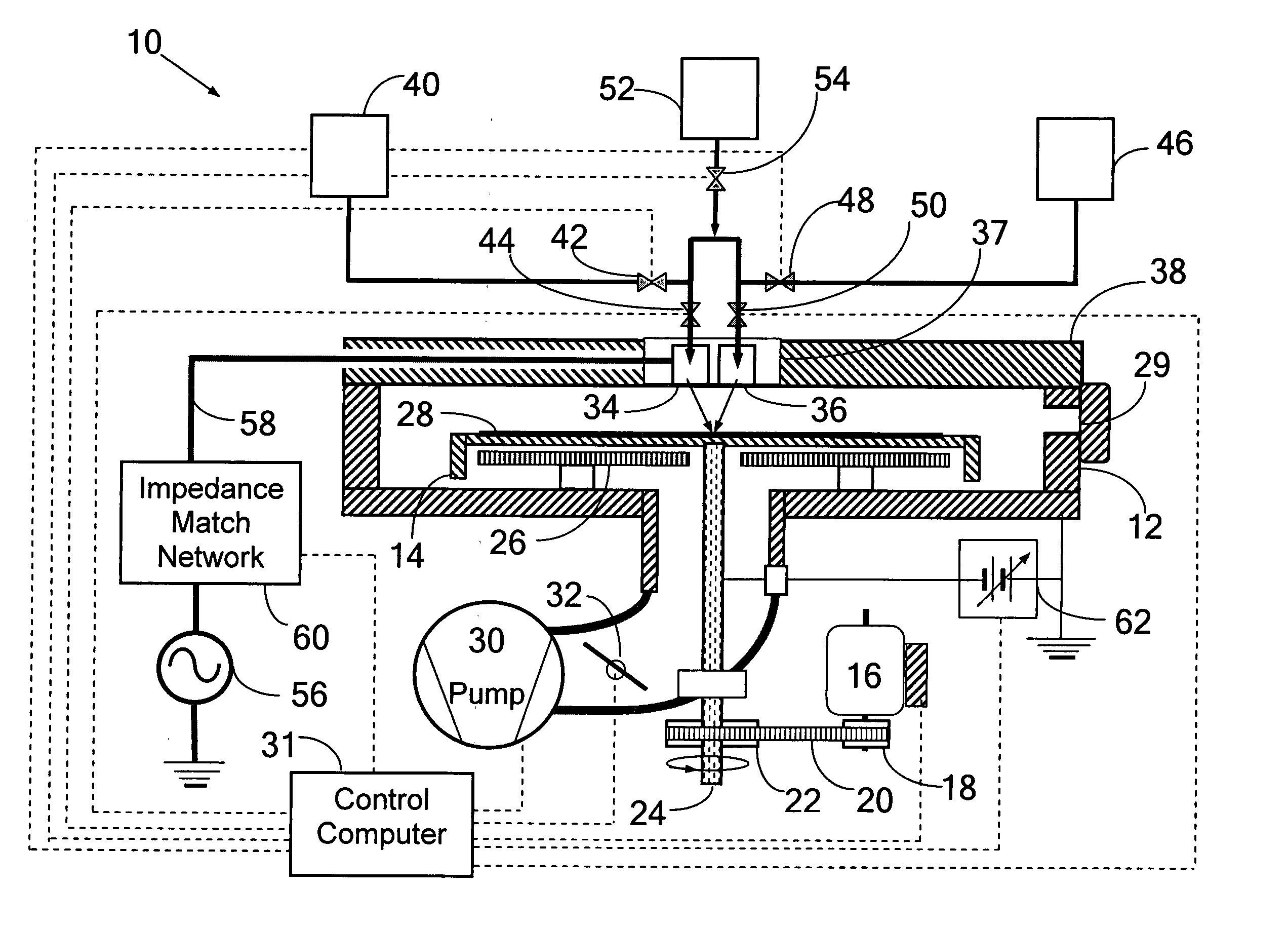

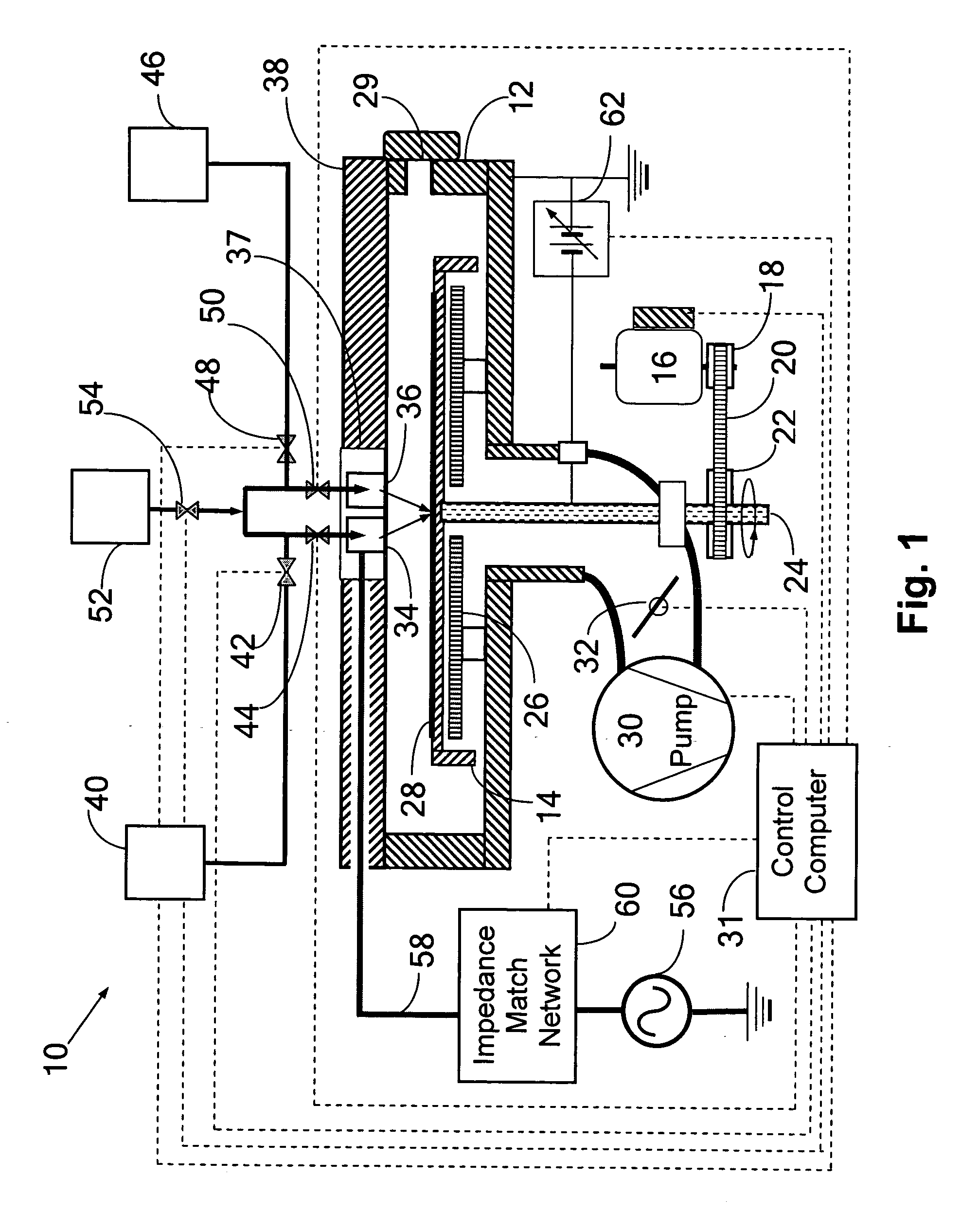

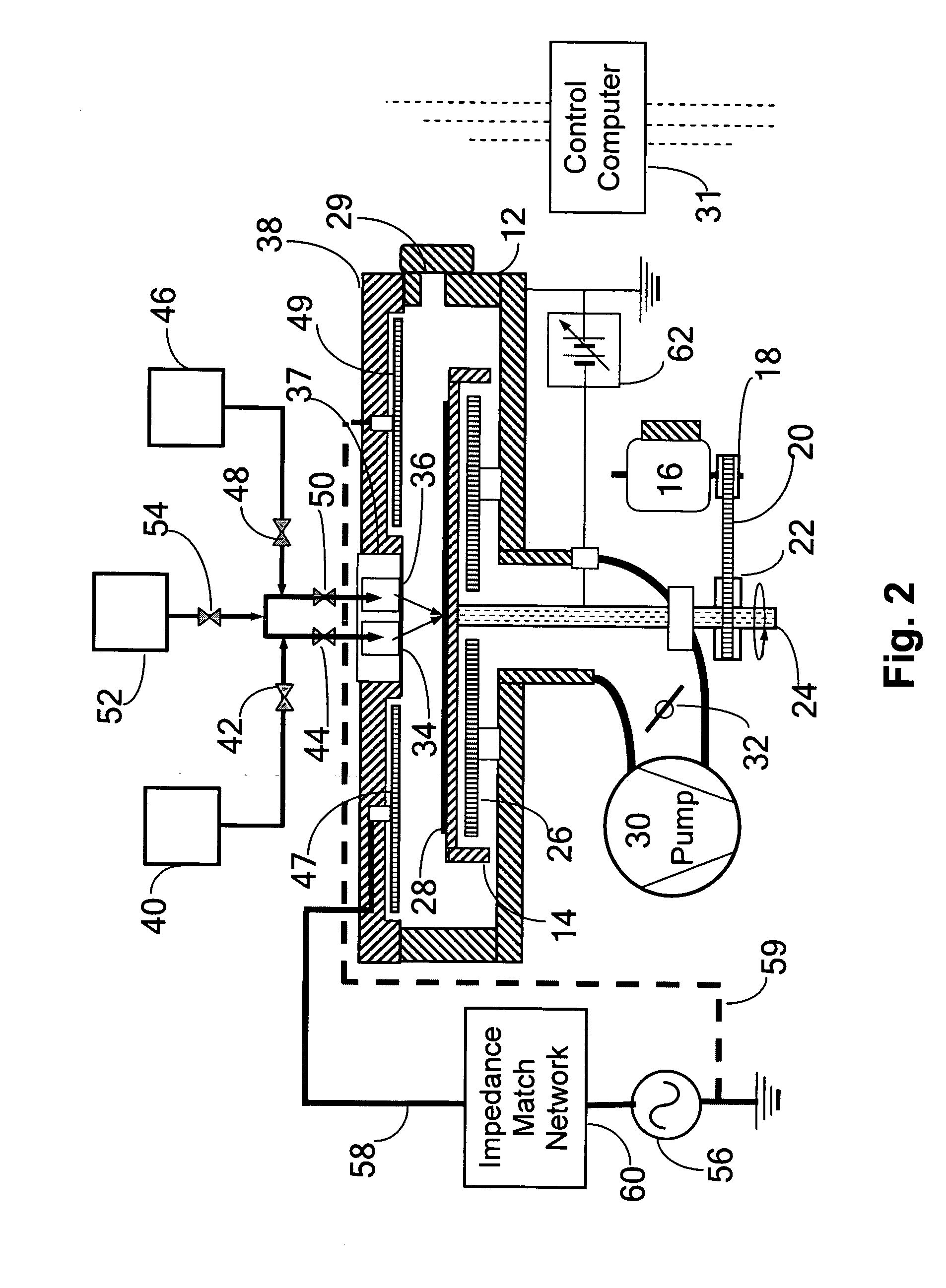

Image

Examples

example-- 2

EXAMPLE--2

[0078] Deposition of Metal Oxides: A variety of oxides of metals can be deposited by employing metal halides along with the plasma of hydrogen and oxygen mixture (alternatively water and hydrogen plasma) injected in combination with hydrogen, helium or argon as a non-condensable gas. Reaction of hydroxyl and associated reactive species in the plasma with metal halide monolayer generates metal oxides. The metal halide can be selected with a general formula MX.sub.n where, M: Al, Si, In, Sn, Pb, Ba, Sr, Ni, Ti, Ta, Zr, Nb, Hf, Mo, W, Fe, Co, Ni, Co, and Cu and other transition metals. Whereas, X=F, Cl, Br or 1.

example-- 3

EXAMPLE--3

[0079] Deposition of Metal Nitrides: A variety of oxides of corresponding metals can be deposited by employing metal halides through the first injector with hydrogen as a non-condensable gas and ammonia as the second chemical precursor. Alternately, NH.sub.x species can be conveniently generated by pulsing N.sub.2 in hydrogen plasma. The overall reaction can be described as:

[0080] MX.sub.n+Surface.fwdarw.MX.sub.n (adsorbed)

[0081] MX.sub.n (adsorbed)+NHx+H.fwdarw.MNx+n HX

[0082] Examples of M are, but not limited to, Al, Ti, Ta, Zr, Nb, Hf, Mo, W, Co, Ni, Cu and X is selected from F, Cl, Br or 1.

example-- 4

EXAMPLE--4

[0083] Deposition of Metal Carbides: Metal carbides are deposited by employing hydrogen as a non-condensable gas with methyl halide (CH.sub.3X, X=F, Cl, Br and 1) as a carbon precursor and metal halides as the metal precursor in hydrogen plasma. Some examples of metal halides are: SiCl.sub.4, TiCl.sub.4, WF.sub.6, MoF.sub.6, TaCl.sub.5, ZrCl.sub.5 etc. The mechanism of deposition of carbides can be described as:

[0084] MX.sub.n+surface.fwdarw.MX.sub.n (adsorbed)

[0085] MX.sub.n (adsorbed)+CH3X+H.fwdarw.MC.sub.y+n HX

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com