Lubricant including water dispersible base

a technology of dispersible base and lubricant, which is applied in the field of lubricant oils, can solve the problems of cylinder wall and piston ring wear, and achieve the effects of reducing the cost of formulation, high temperature detergency, and improving the efficiency of marine cylinder lubrican

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0128] Water in oil emulsions containing .about.20% w / w KOH aqueous solution (35% KOH w / w) and .about.80% w / w oil formulation were prepared. The oil formulation contains 1-2% w / w emulsifying surfactants, .about.2% w / w dispersant, .about.3% w / w antioxidant, .about.1% w / w aliphatic solvent and 92-93% w / w SAE-50 oil.

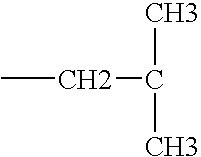

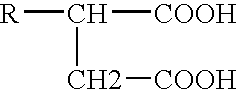

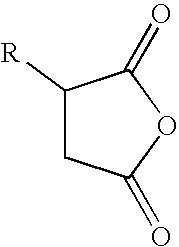

[0129] The emulsifiers play an important role in the emulsion preparation and storage stability. The first emulsifier of a blend of two emulsifiers used to prepare the examples was a PIBSA:EG:DMEA, polyisobutenyl succinic anhydride:ethylene glycol:dimethyl ethanol amine-2:1:2 (eq). This emulsifier has a high molecular weight polyisobutylene chain (.about.1500 MW) and a low HLB. Emulsifier two was a co-emulsifier. HDSA:DMEA, dodecahexylene succinic anhydride: dimethyl ethanol amine 1:1 (eq.) It has a low molecular weight and a high HLB. The structures of these two emulsifiers are presented below.

Emulsifiers Used in the Laboratory Manufacture of Water / Marine Lubricating Oil E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average particle size | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com