Chemical supply system

a chemical supply and pump technology, applied in the direction of diaphragm valves, instruments, cleaning using liquids, etc., can solve the problems of increasing the difficulty of avoiding the increase of the scale and complexity of the whole apparatus, and the increase of the cleaning speed of the substrate cleaning apparatus, etc., to achieve easy and rapid compounding, reduce/simplification of the scale of the whole system, and move easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first example

A substrate cleaning apparatus of this example is in which wafers are loaded one by one and a cleaning liquid is supplied with rotating the wafer in a circumferential direction, and a single wafer spin cleaning apparatus capable of realizing wide-ranging functions in a wet cleaning process for semiconductor wafers or the like.

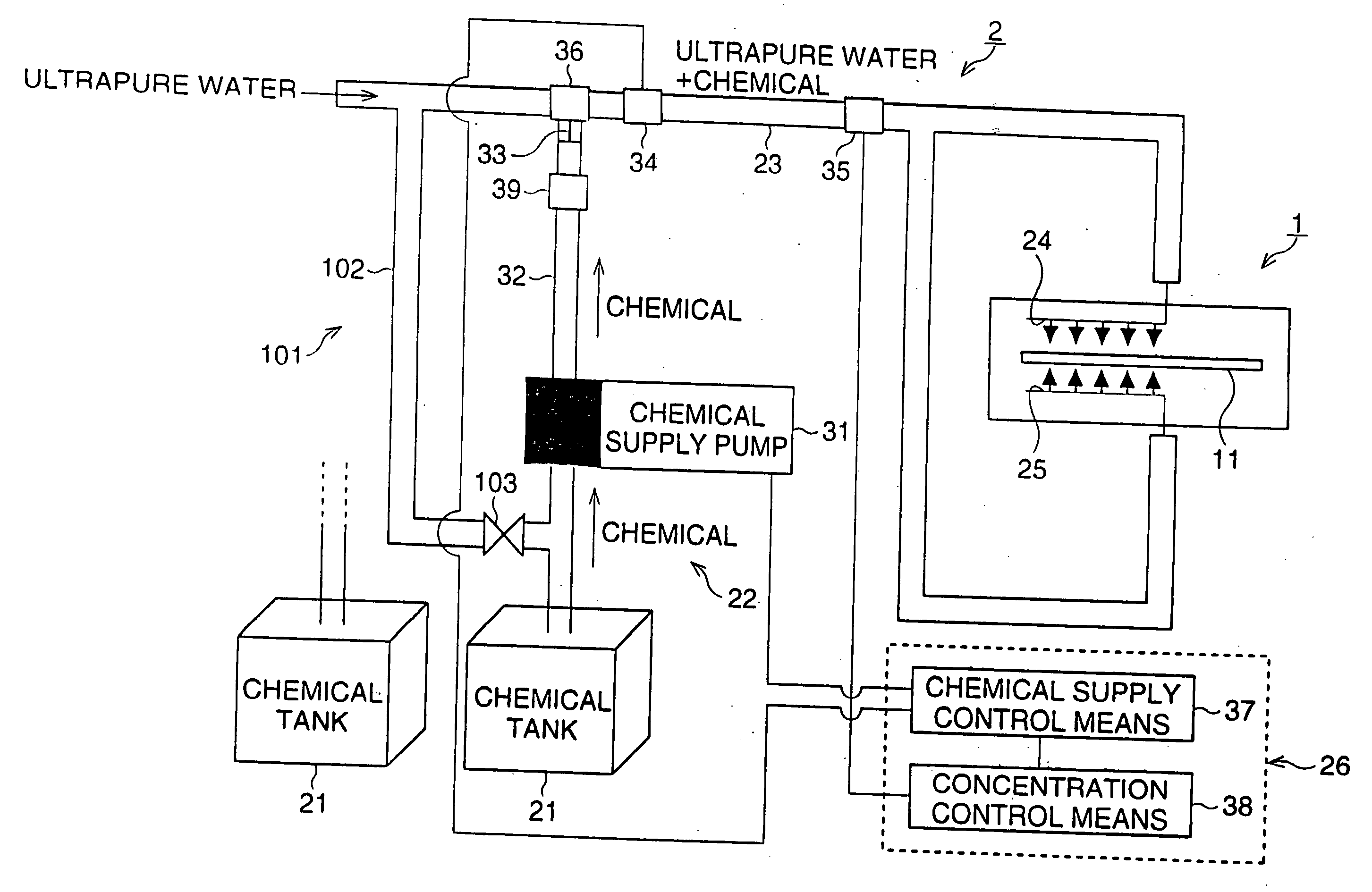

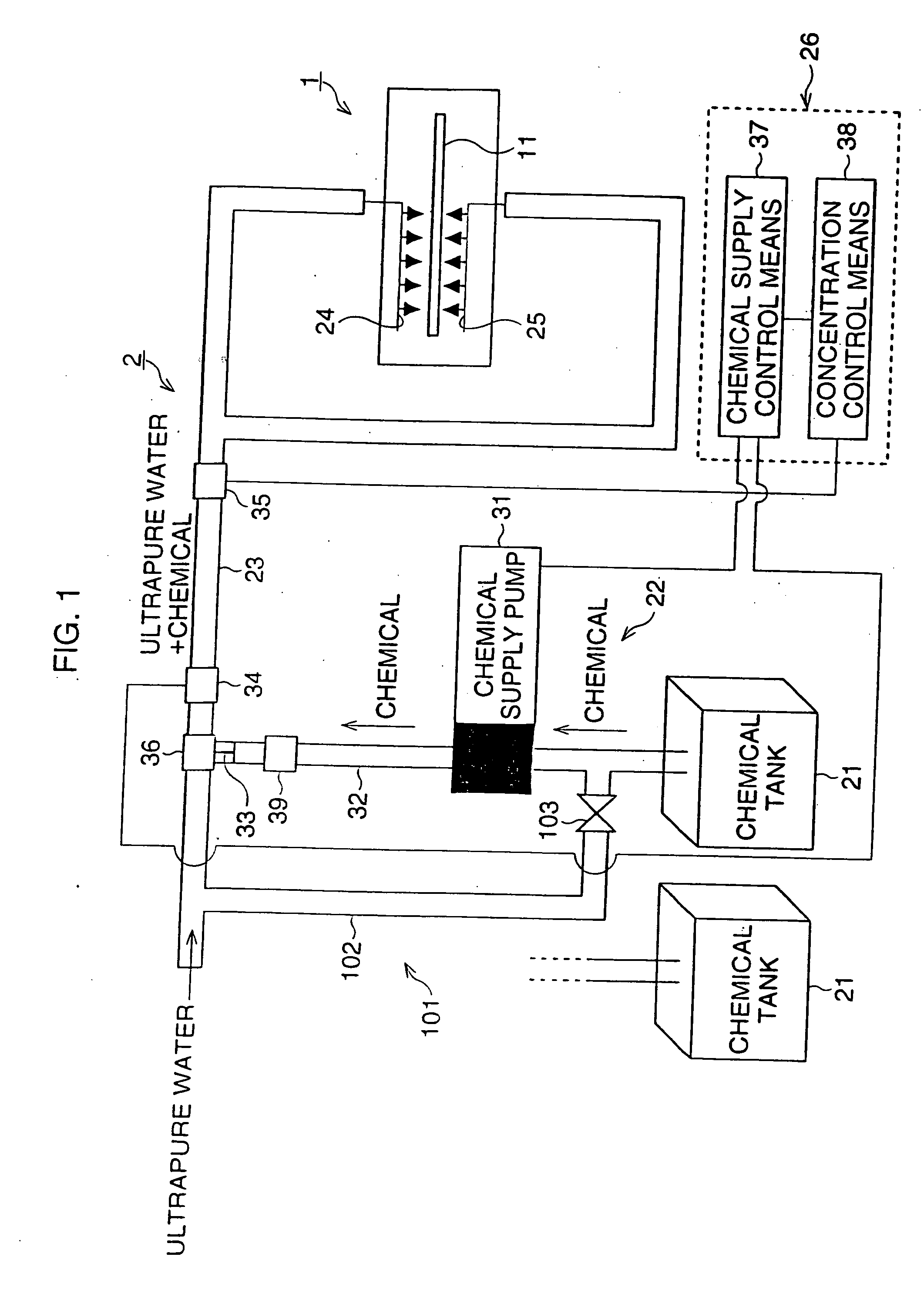

FIG. 1 is a schematic sectional view showing the whole construction of the substrate cleaning apparatus of this example.

This substrate cleaning apparatus is constructed by comprising a cleaning chamber 1 in which a substrate (wafer) 11 is set and cleaning is performed, and a chemical supply system 2 for producing and supplying a cleaning liquid at a desired chemical concentration.

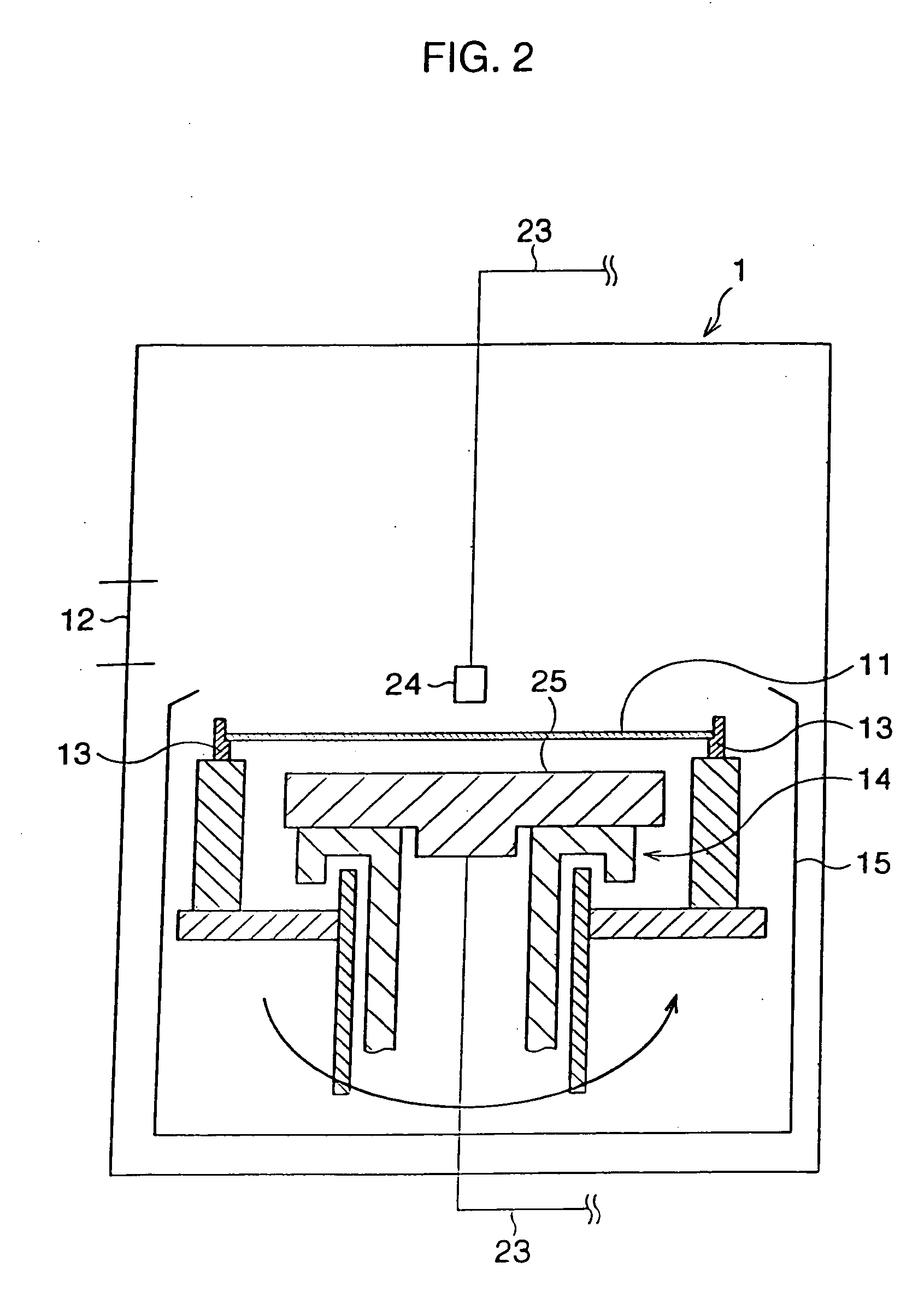

As shown in FIG. 2, the cleaning chamber 1 defines a closed space wherein the wafer 11 to be cleaned is received, and is provided with a gate valve 12 that is a taking in / out portion for the wafer 11. This cleaning chamber 1 is constructed by comprising a wafer set means 14 havin...

second example

Successively, the second example of the present invention will be described. In this example, like the first example, a substrate cleaning apparatus of single wafer spin cleaning type comprising a cleaning chamber and a chemical supply system, is disclosed, but it differs on the point that the construction of the chemical supply apparatus of the chemical supply system is different. The same components or the like as those of the substrate cleaning apparatus of the first example are denoted by the same references, and their explanations will be omitted.

FIG. 35 is a schematic sectional view showing the whole construction of the substrate cleaning apparatus of this example.

The substrate cleaning apparatus of this example is constructed by comprising a cleaning chamber 1 and a chemical supply system 2. Here, the chemical supply system 2 is constructed by comprising a chemical storage tank 21, a chemical supply apparatus 121 connected to the chemical storage tank 21 for positively pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com