High efficiency combination direct/indirect water heater

a water heater and high efficiency technology, applied in the direction of water heaters, stationary conduit assemblies, steam generation using hot heat carriers, etc., can solve the problems of low heating efficiency of indirect heating systems, time-consuming and therefore costly, and high cost of the former, so as to facilitate unhindered gas venting and prevent back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention provides a high efficiency combination direct / indirect heater that facilitates both direct and indirect heat transfer to a liquid. For the sake of simplicity, it will be assumed throughout this specification that the liquid being heated is water. A salient feature of the invention is the immersion of a heat transfer surface, such as a combustion gas manifold, in already heated water, thereby enhancing efficiencies.

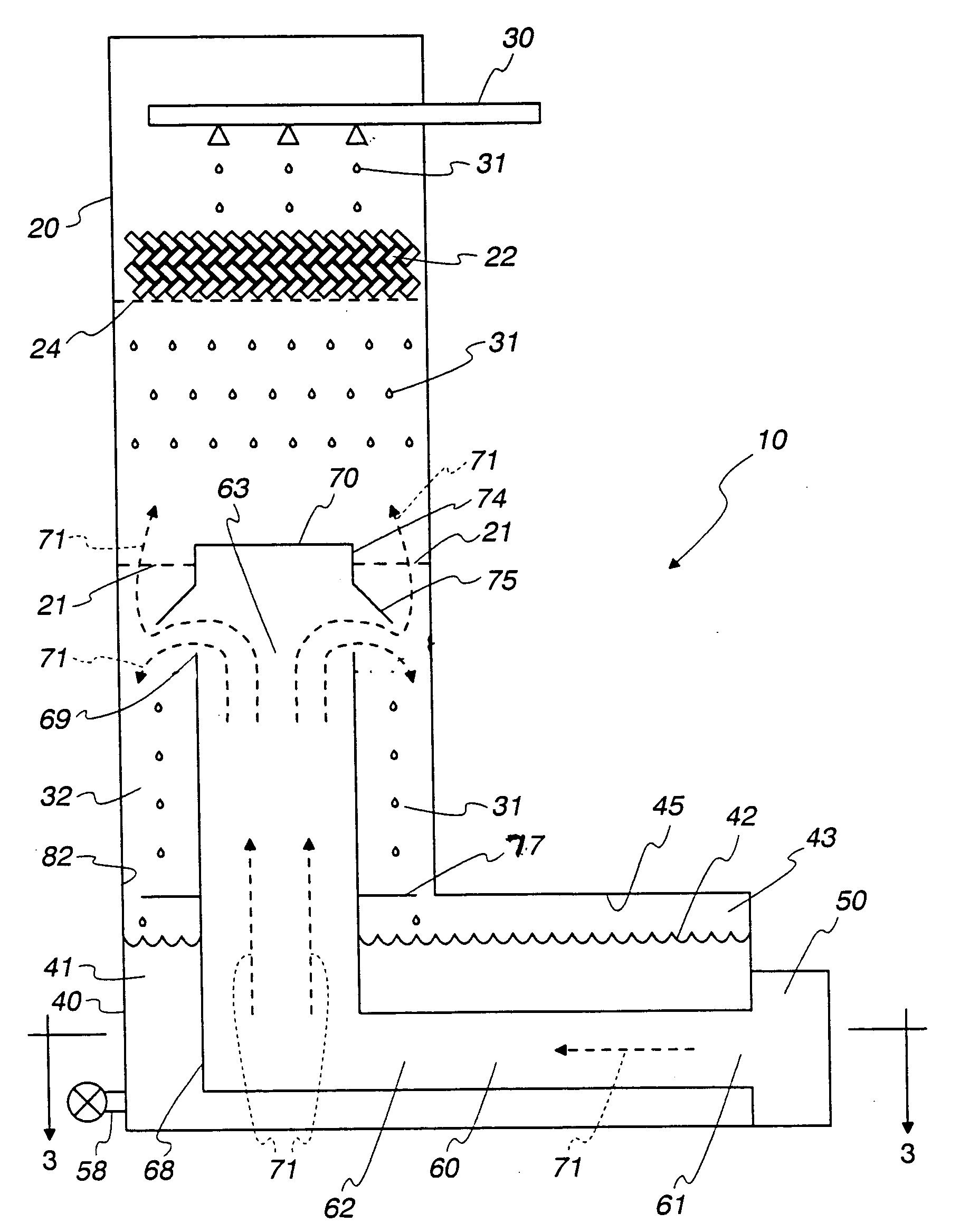

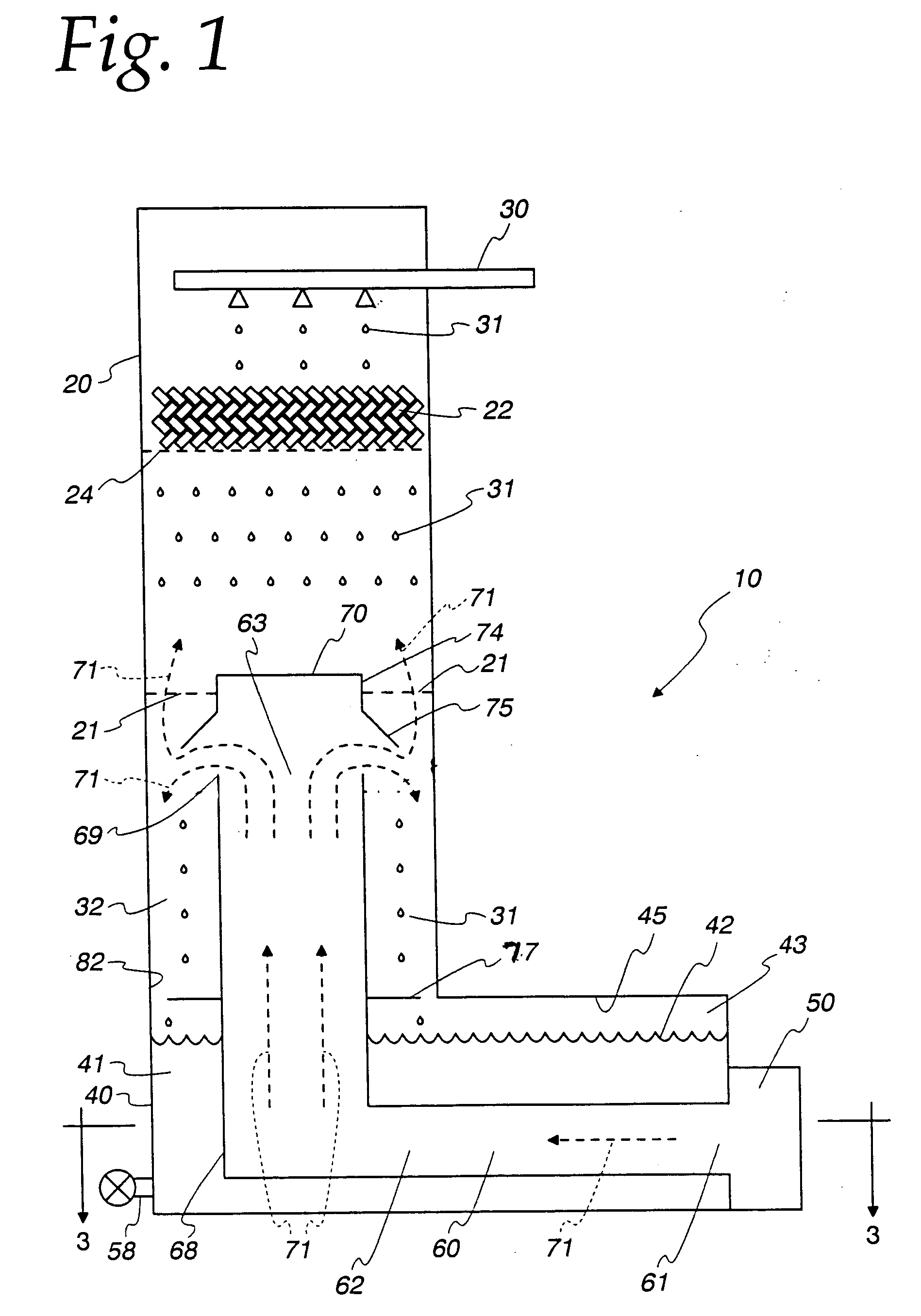

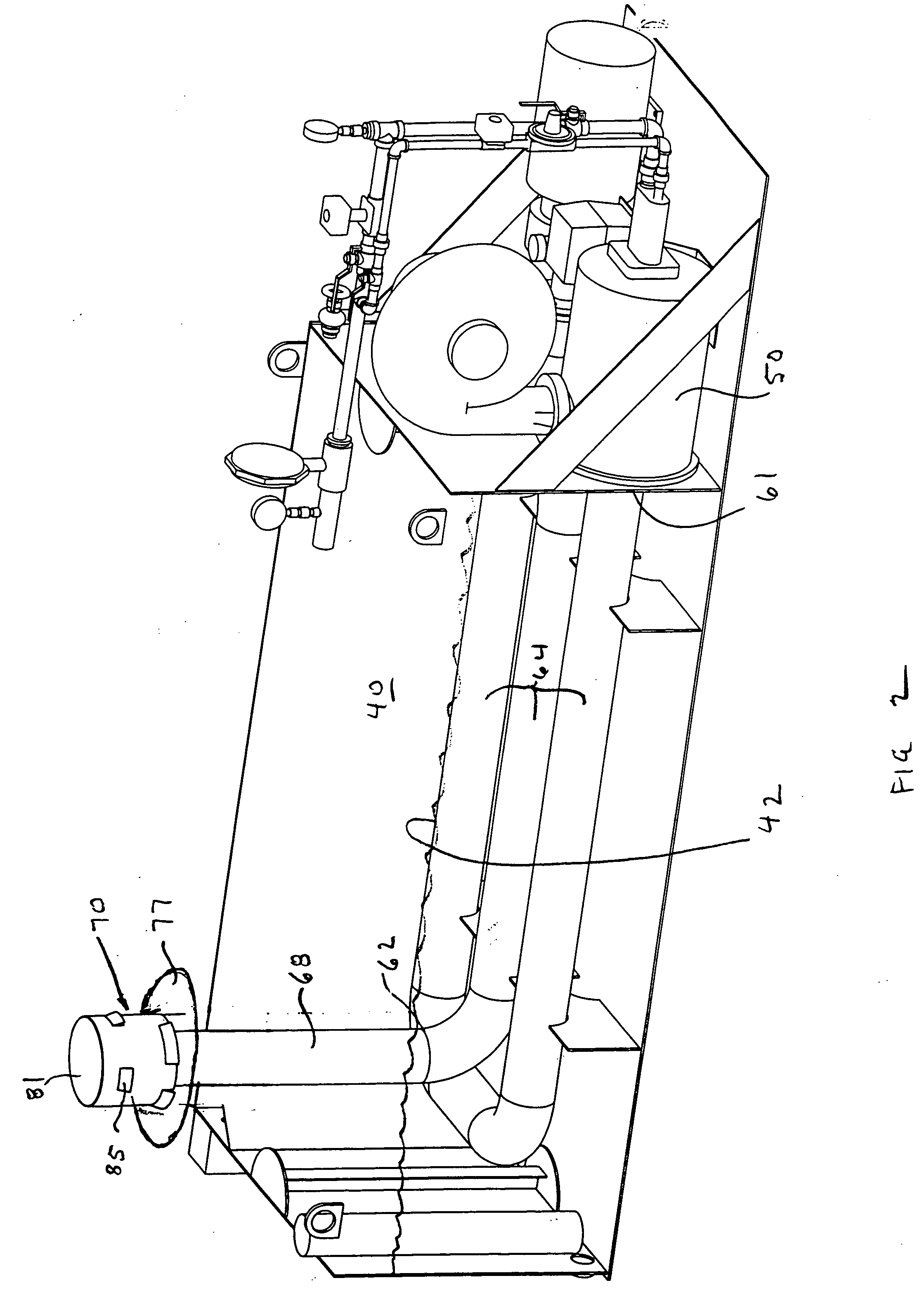

[0030] As shown in FIG. 1, the combination direct / indirect water heater, generally designated as numeral 10 is comprised of five main components: a vertical riser 20 (often called “tower”), a cold water supply inlet 30, a hot water reservoir 40, a fuel burner 50, a hot gas inlet conduit or manifold 60 that is nearly fully submerged in the reservoir 40, and a means for water egress 58. FIG. 2 is a perspective view of the invented combination direct / indirect water heater, without the tower.

[0031] A water supply and distribution means 30 distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com