Barrier compositions and articles made therefrom

a barrier composition and composition technology, applied in the field of barrier compositions and articles made therefrom, can solve the problems of difficult to fabricate commercial packaging solely out of barrier materials, product deterioration, and moisture problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0055] As an example of this invention, cast films consisting of MXD6 nylon and 250 ppm cobalt octoate were prepared in thicknesses from 5 to 35 mils and were tested for oxygen permeations against cast films of MXD6 nylon without cobalt octoate. The results shown below in Table 4 demonstrate the improved oxygen barrier characteristics of films of MXD6 nylon and cobalt octoate.

TABLE 4oxygen permeation(ccmil / m*2 day)(green castfilms at 0% RH)Variablesthickness (mils)36 (hrs)84180276324I. MXD6 film5171551112915139——19301212——32933813712II. MXD6 film +5 8310.30.5250 ppm Co11—00——192310——353900——

example 2

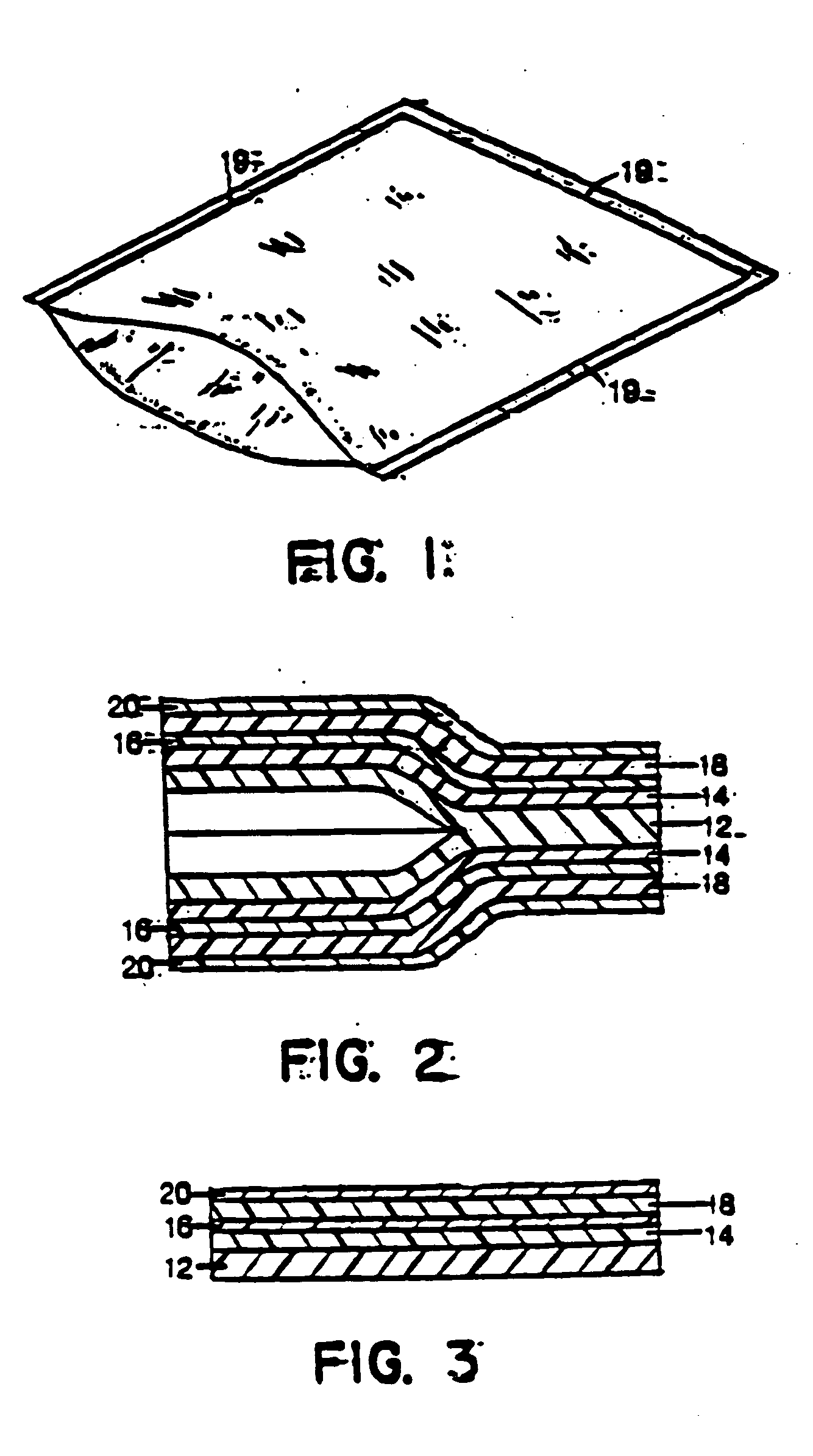

[0056] A three layer structure of the present invention having outer layers of PET and a core layer of MXD6 nylon / 100 ppm cobalt octoate blend (wherein the core layer comprised 10% of the structure) was used to produce bottles on a Nissei stretch blow molding machine. Other bottles were produced by the same means and from similar material except the core layer did not contain cobalt. After the bottles were aged for three months at 0% relative humidity, they were tested for oxygen permeation. The results are shown below in table 5.

TABLE 5thicknessoxygen permeationVariables(mils)(ccmil / m* 2 day)(1) PET / MXD6 / PET2742(2) PET / MXD6 + 100 ppm Co / PET28 9

*Oxygen barrier is normalized by total thickness, not by barrier thickness

example 3

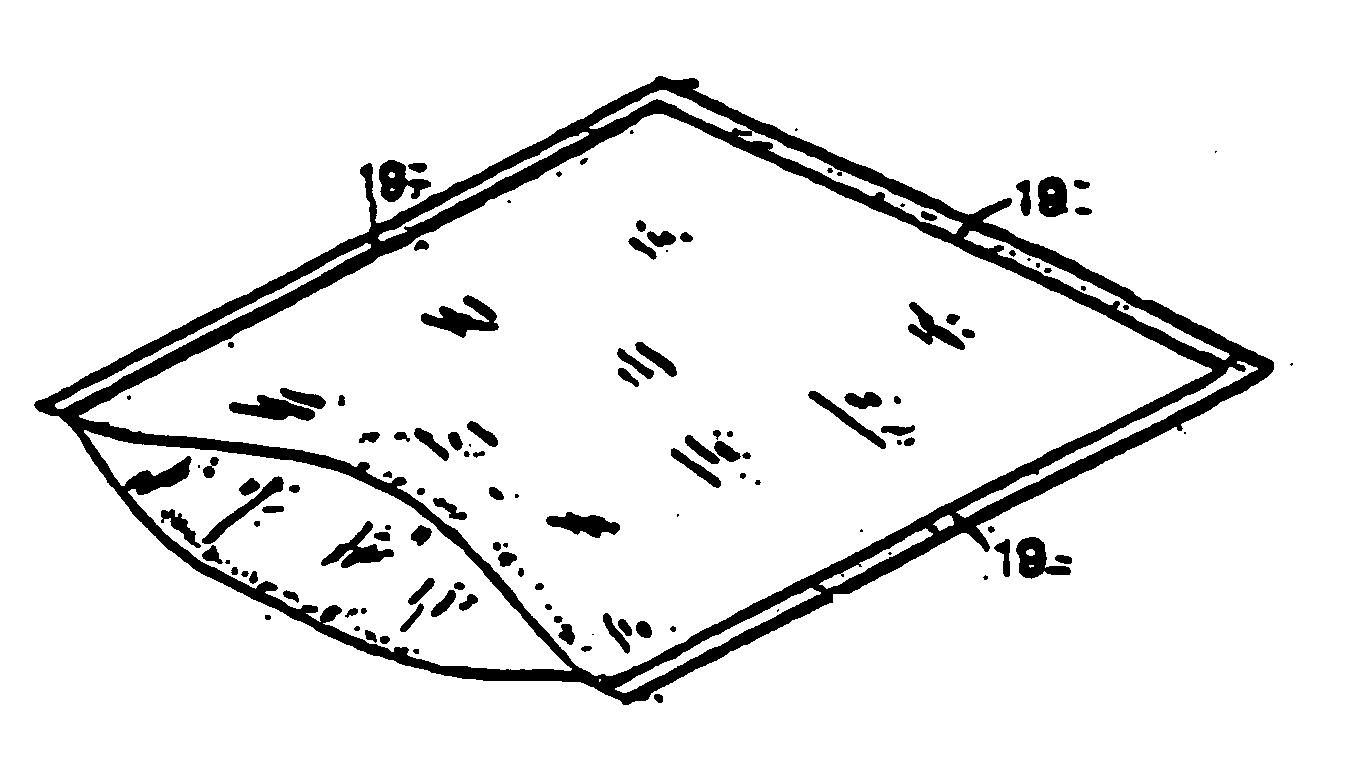

[0057] Flexible lidstock or pouches can be formed from coextruded film structures in accordance with the present invention having a core layer of a blend of MXD6 nylon and cobalt octoate disposed between two layers of nylon 6. The film was tested before and after retort for oxygen permeation at test conditions of 100% oxygen, 0% relative humidity (RH) and at 100% oxygen, 100% RH. The results are

TABLE 6(TEST CONDITIONS: 100% OXYGEN; 0% RH; UNAGED SAMPLE)TOTALSTEADY STATETHICKNESSPERMEATIONSAMPLE(MILS)RATE*POST RETORT NYLON 6 / 1 MIL MXD6 + 120 PPM Co / NYLON 63.536.2PRE RETORT NYLON 6 / 2 MIL MXD6 + 120 PPM Co / NYLON 64.440.1POST RETORT NYLON 6 / 2 MIL MXD6 + 120 PPM Co / NYLON 64.740.1PRE RETORT NYLON 6 / 1 MIL MXD6 + 250 PPM Co / NYLON 63.310.6POST RETORT NYLON 6 / 1 MIL MXD6 + 250 PPM Co / NYLON 63.383.2PRE RETORT NYLON 6 / 2 MIL MXD6 + 250 PPM Co / NYLON 64.500.0POST RETORT NYLON 6 / 2 MIL MXD6 + 250 PPM Co / NYLON 64.840.0PRE RETORT NYLON 63.1448.0POST RETORT NYLON 62.8839.4

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| RH | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com