Oil recovery using non-cryogenically produced nitrogen and off-gas recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In this specification, the terms “oil well”, “formation”, and “reservoir” are used interchangeably to identify a natural underground source of liquid oil.

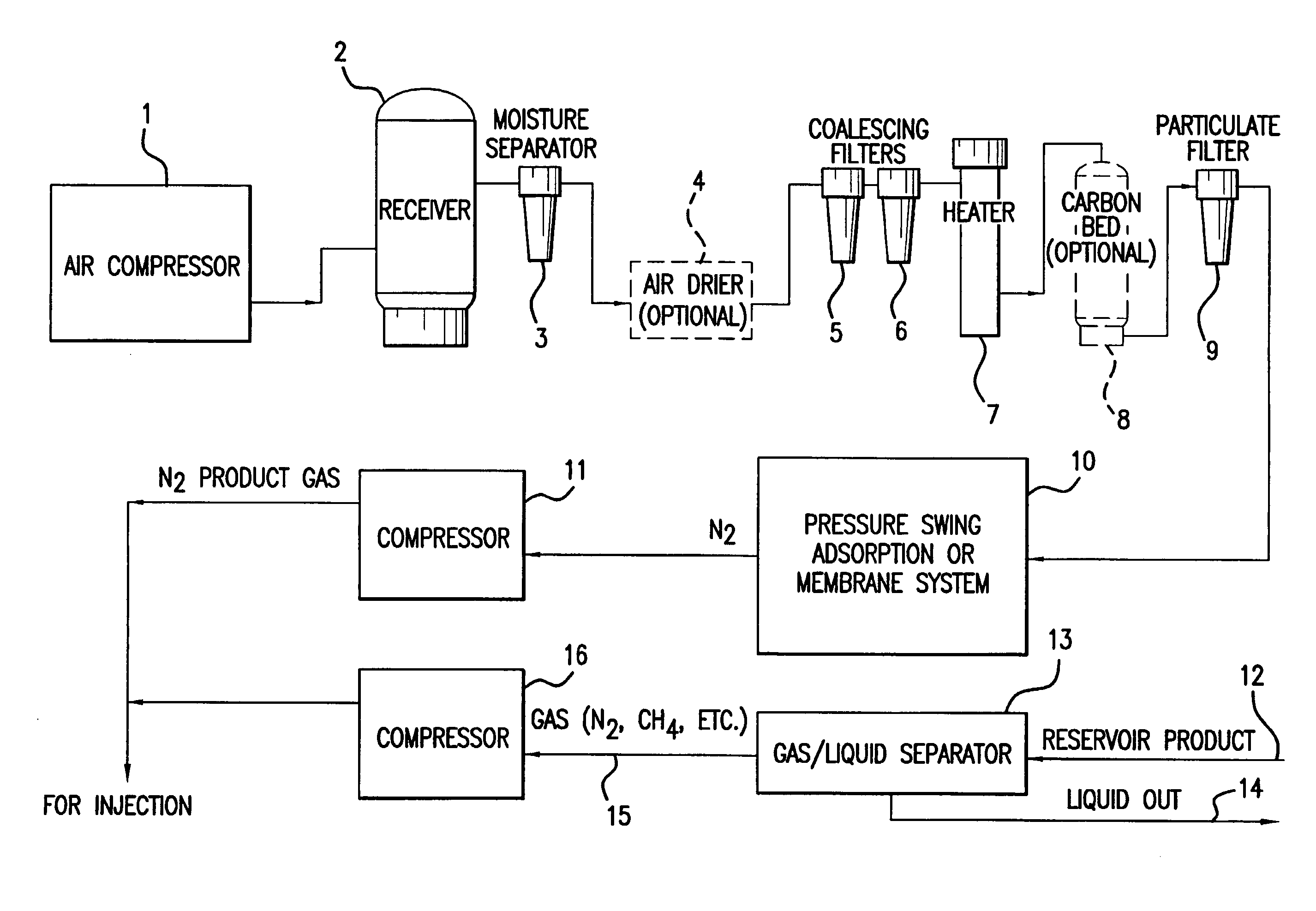

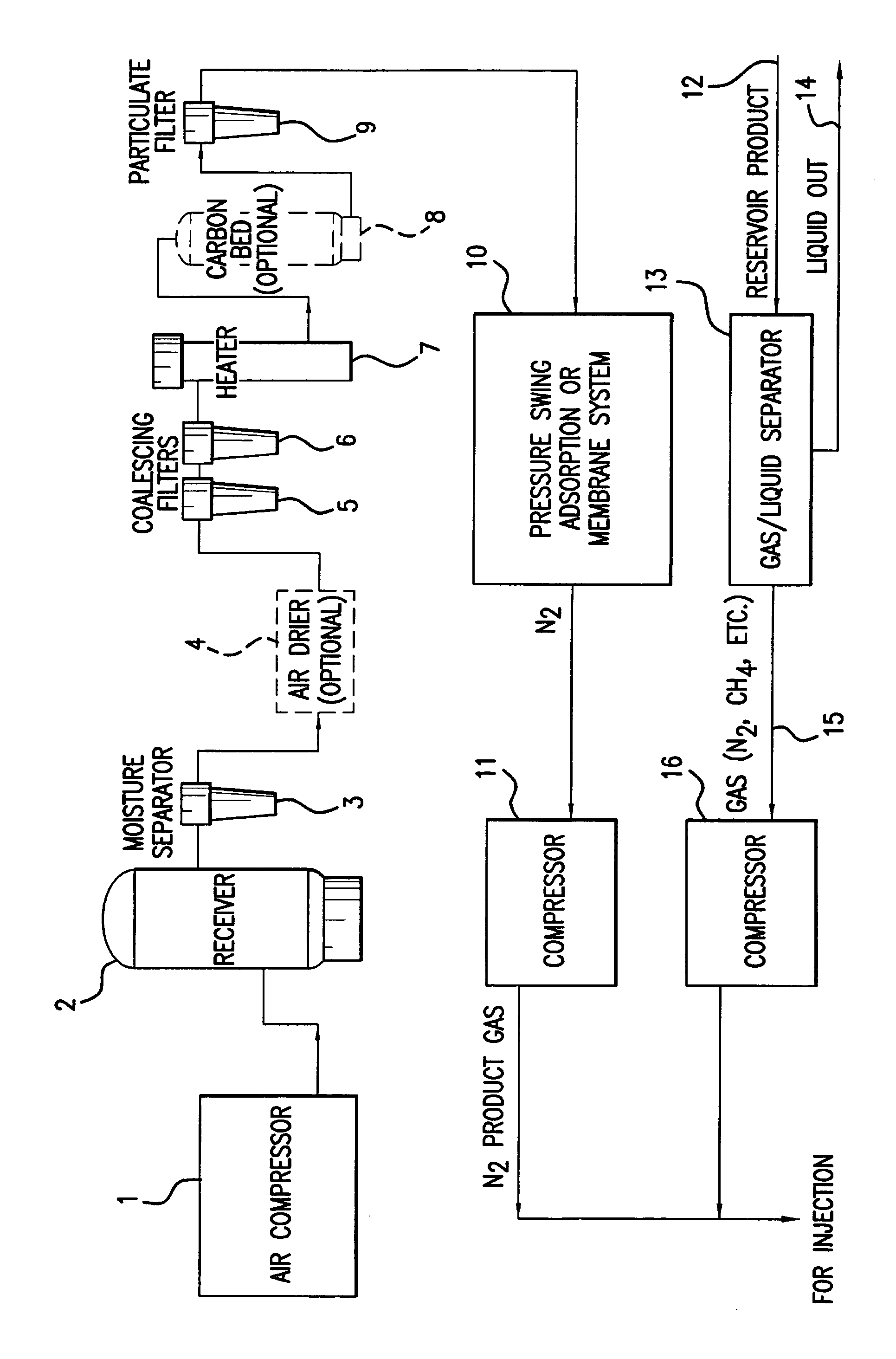

[0019] The FIGURE provides a schematic diagram of the components of a system used to practice the present invention. The system is preferably physically located at or near the site of an oil well.

[0020] Air compressor 1 takes ambient air and compresses it. The compressed air passes through receiver 2 and moisture separator 3. The air may then pass through an optional air dryer 4. The air passes through coalescing filters 5 and 6, and heater 7. Air leaving the heater may pass through an optional carbon bed 8, and then through particulate filter 9.

[0021] Air leaving the particulate filter enters air separator 10, which may be either a membrane system or a pressure swing adsorption (PSA) unit. The air separator converts the incoming air into two streams, one which is oxygen-enriched and the other which is oxygen-depleted (ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com