Gallium-containing light-emitting semiconductor device and method of fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

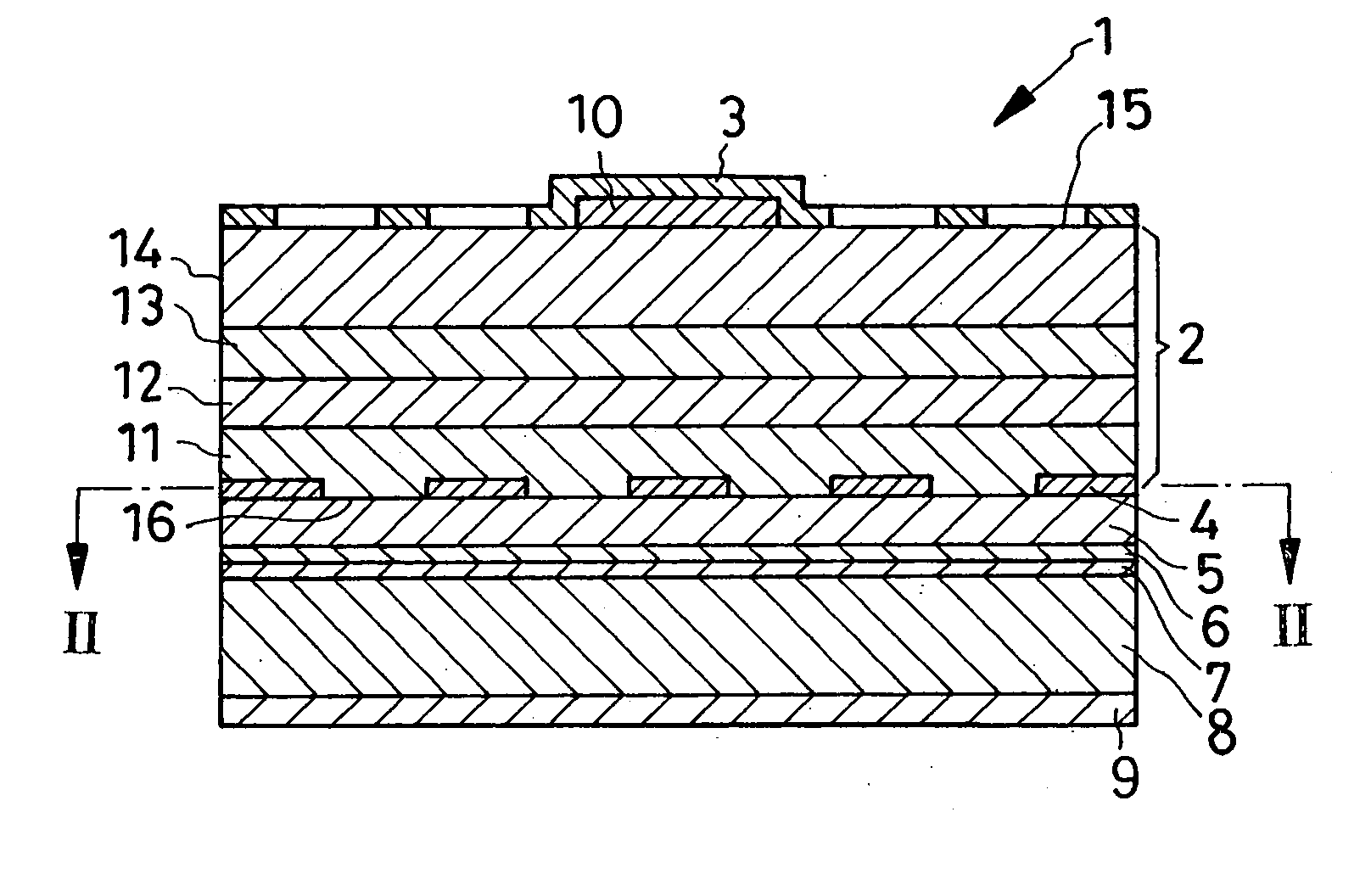

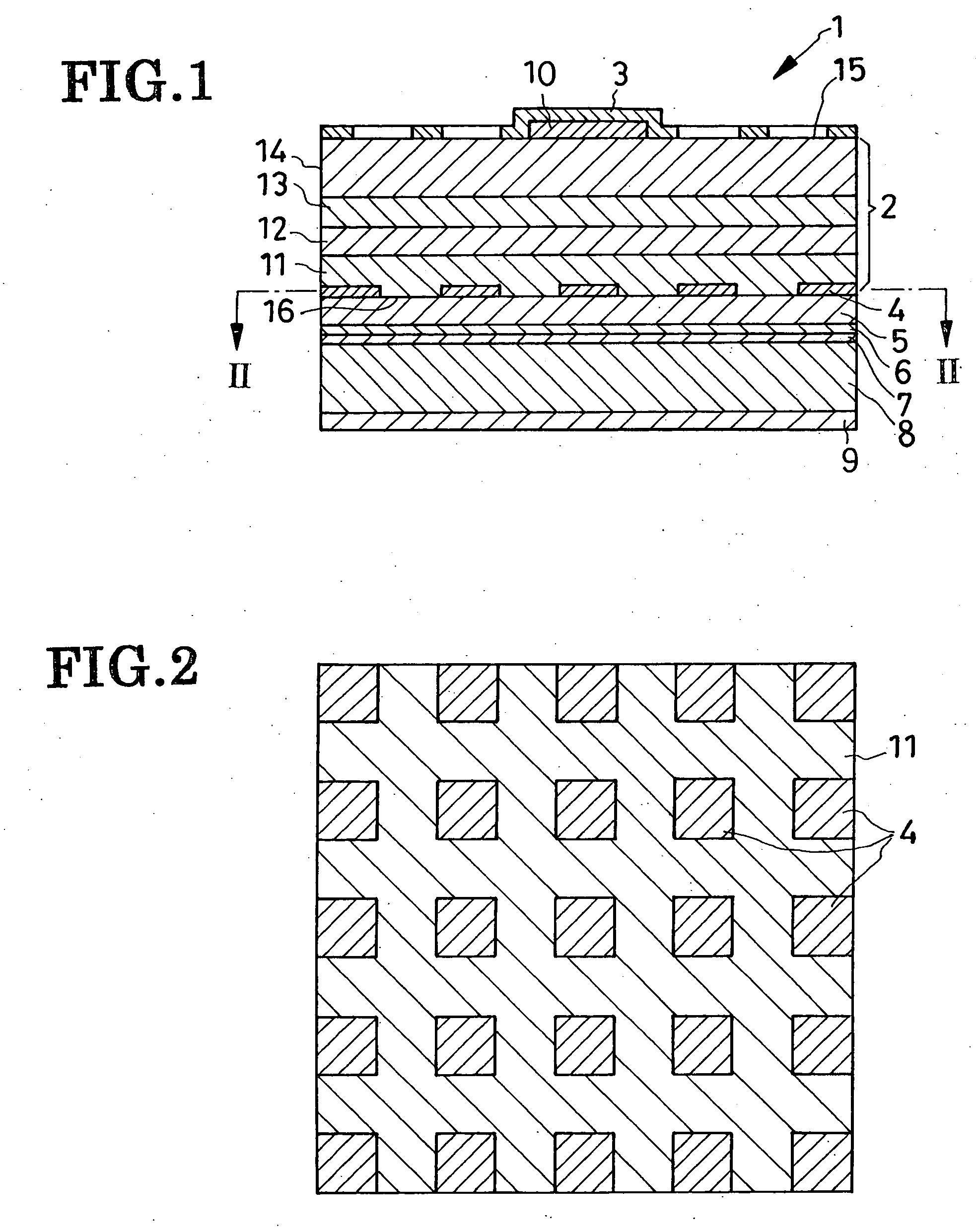

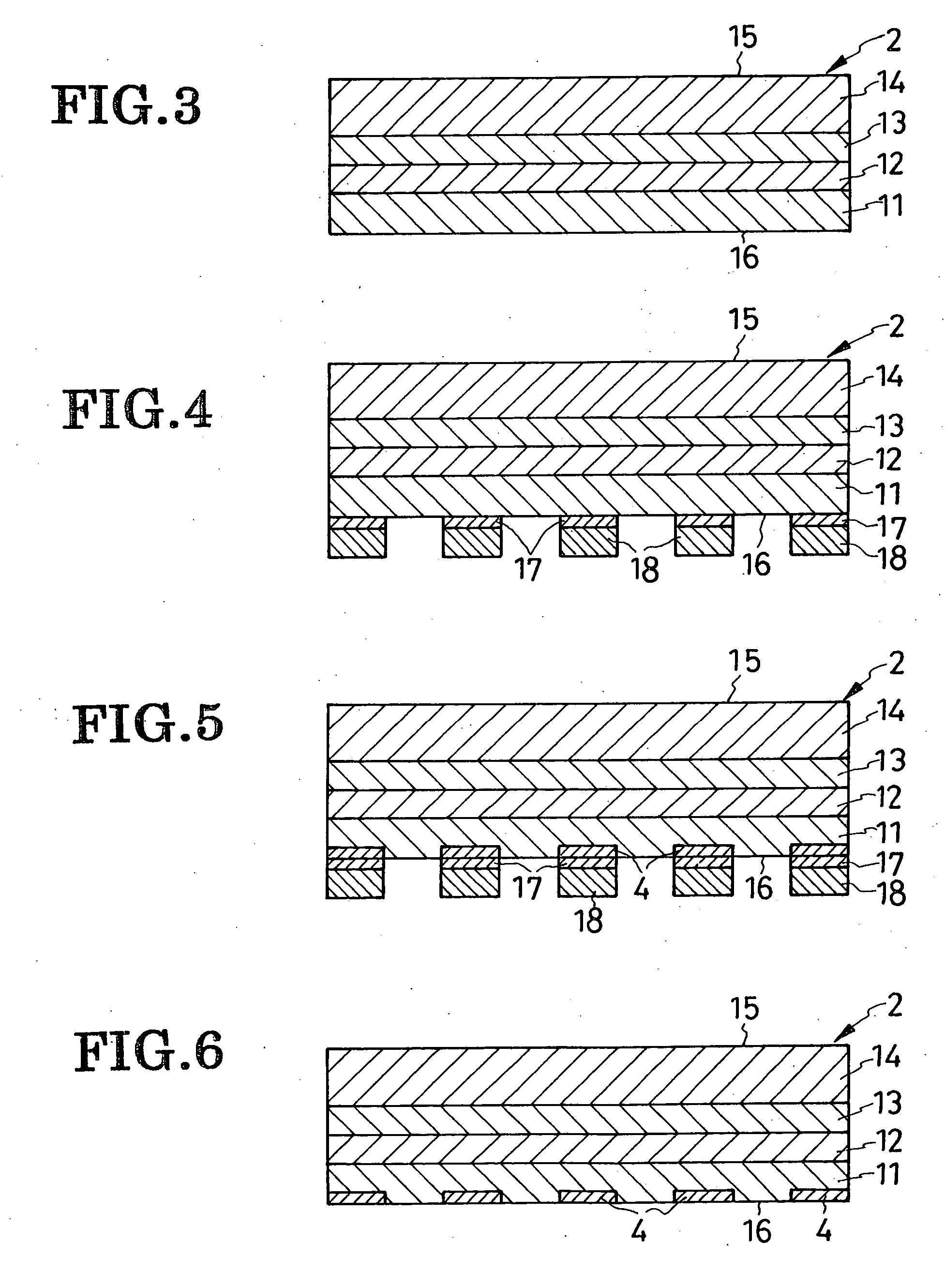

Image

Examples

embodiment

of FIG. 10

[0082] Another preferred form of LED 1a shown in FIG. 1 has an integral ohmic contact region 4a covering the entire bottom surface 16 of the lower cladding 11. A relatively high efficiency is nevertheless obtainable because the total reflectivity of the ohmic contact region 4a and reflective layer 5 is as high as 60 percent. As the ohmic contact region 4a is larger than all the isolated ohmic contact regions 4 of FIGS. 1 and 2 combined, so much is reduced the resistance to forward current flow, with a corresponding diminution of power loss.

[0083] Another feature of the alternative LED 1a resides in a metal-made baseplate 8a which is affixed to the reflective layer 5 under heat and pressure in place of the silicon baseplate 8 of the previous embodiment. No dedicated cathode is provided as the baseplate 8a serves as both mechanical support and cathode.

[0084] The alternative LED 1a is akin to the first disclosed LED 1 in all the other details of construction. The integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com