Electrolytic processing apparatus and method

a processing apparatus and electrolysis technology, applied in the direction of electrolysis process, electrolysis components, tanks, etc., can solve the problems of not being able to meet the requirements of plating solutions, the development of plating solutions is facing such a difficult technical problem, and the production cost is reduced, so as to achieve the effect of reducing production costs and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

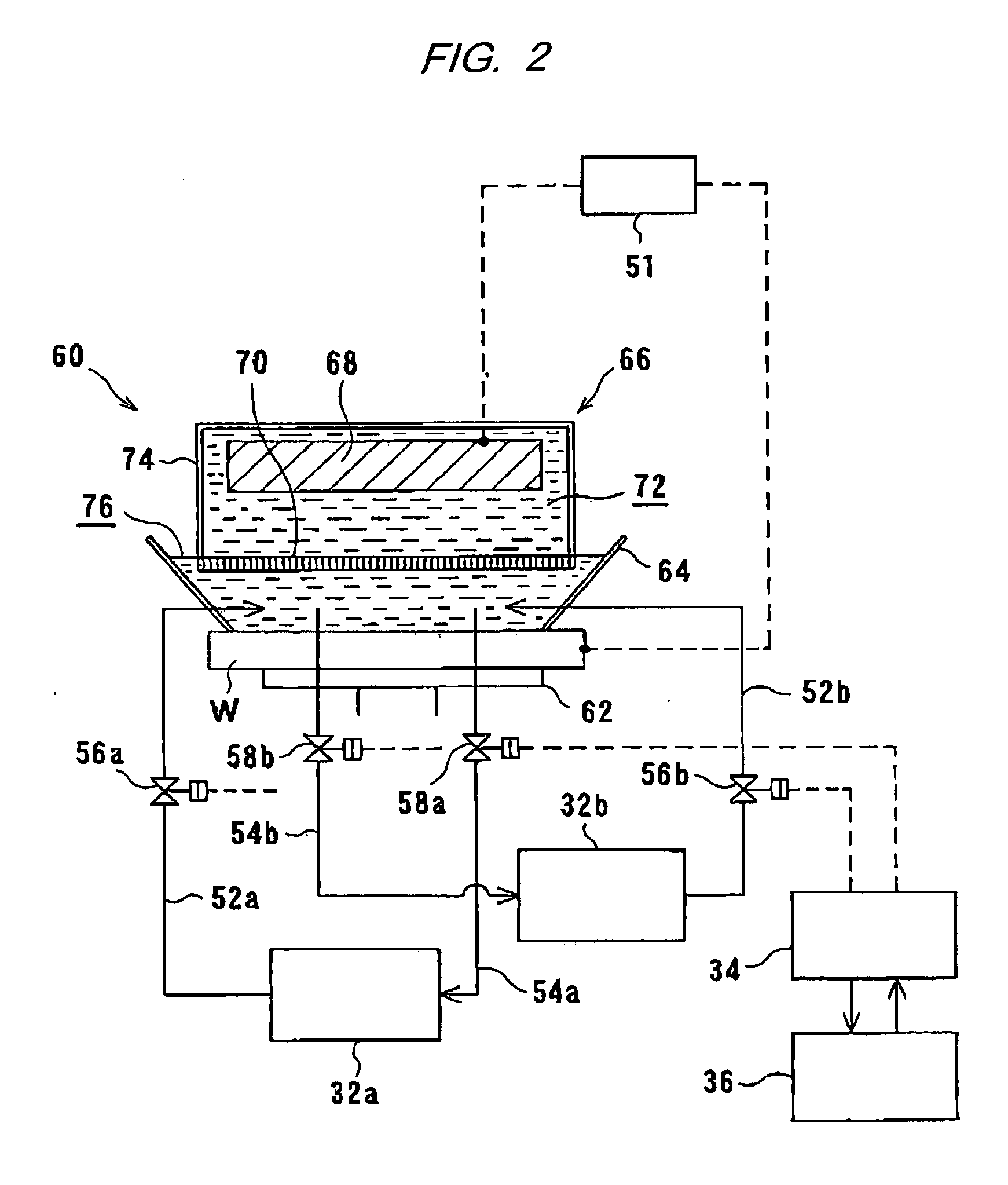

[0044] Preferred embodiments of the present invention will now be described with reference to the drawings. Though the following embodiments relate to application of the present invention to electroplating apparatuses, such apparatuses may of course be used as electrolytic etching apparatuses by applying a voltage, which allows an electric current to flow in a direction opposite to the direction of electric current in plating, between a substrate and a counter electrode plate while supplying an electrolysis solution (etching liquid) therebetween.

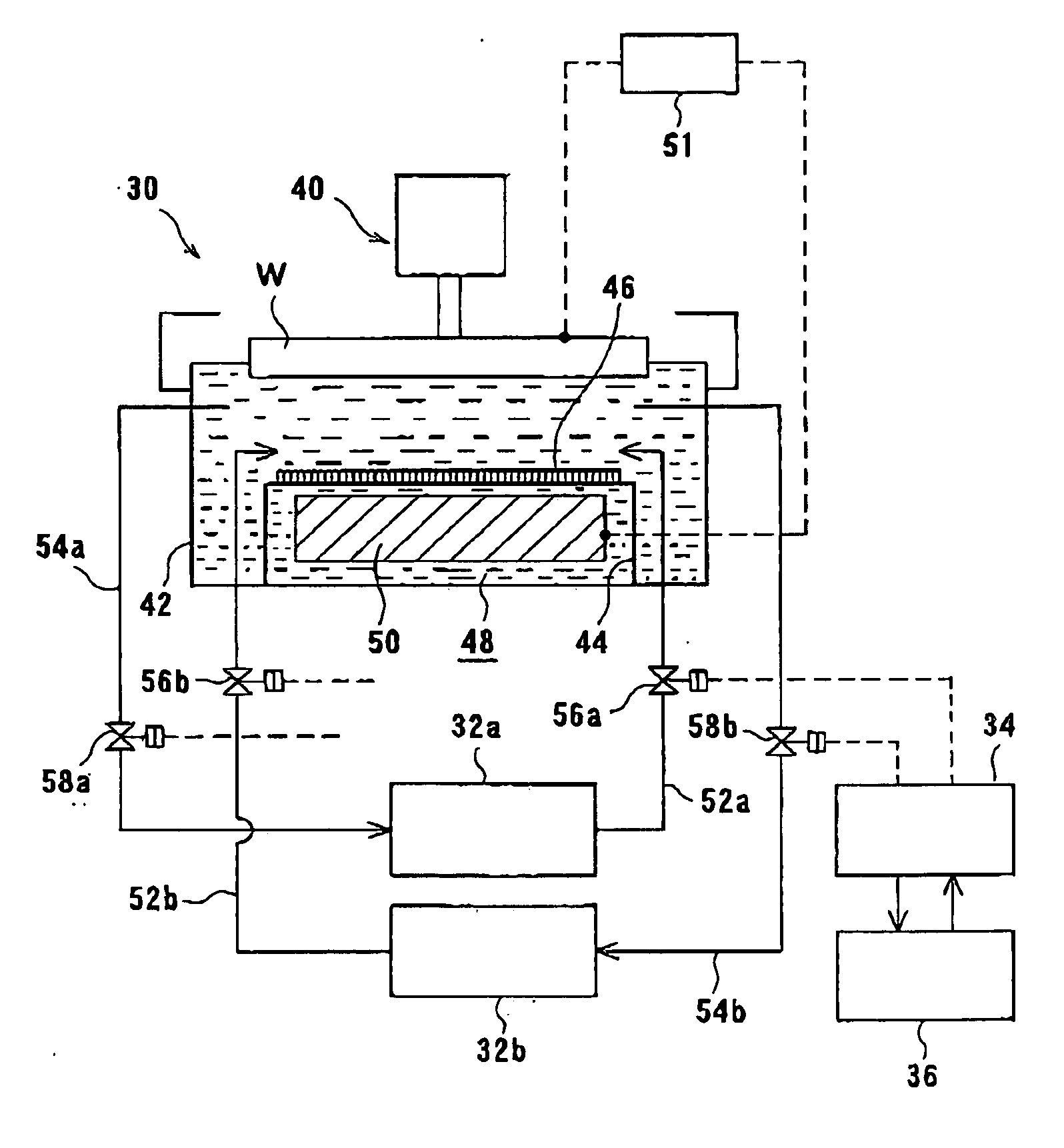

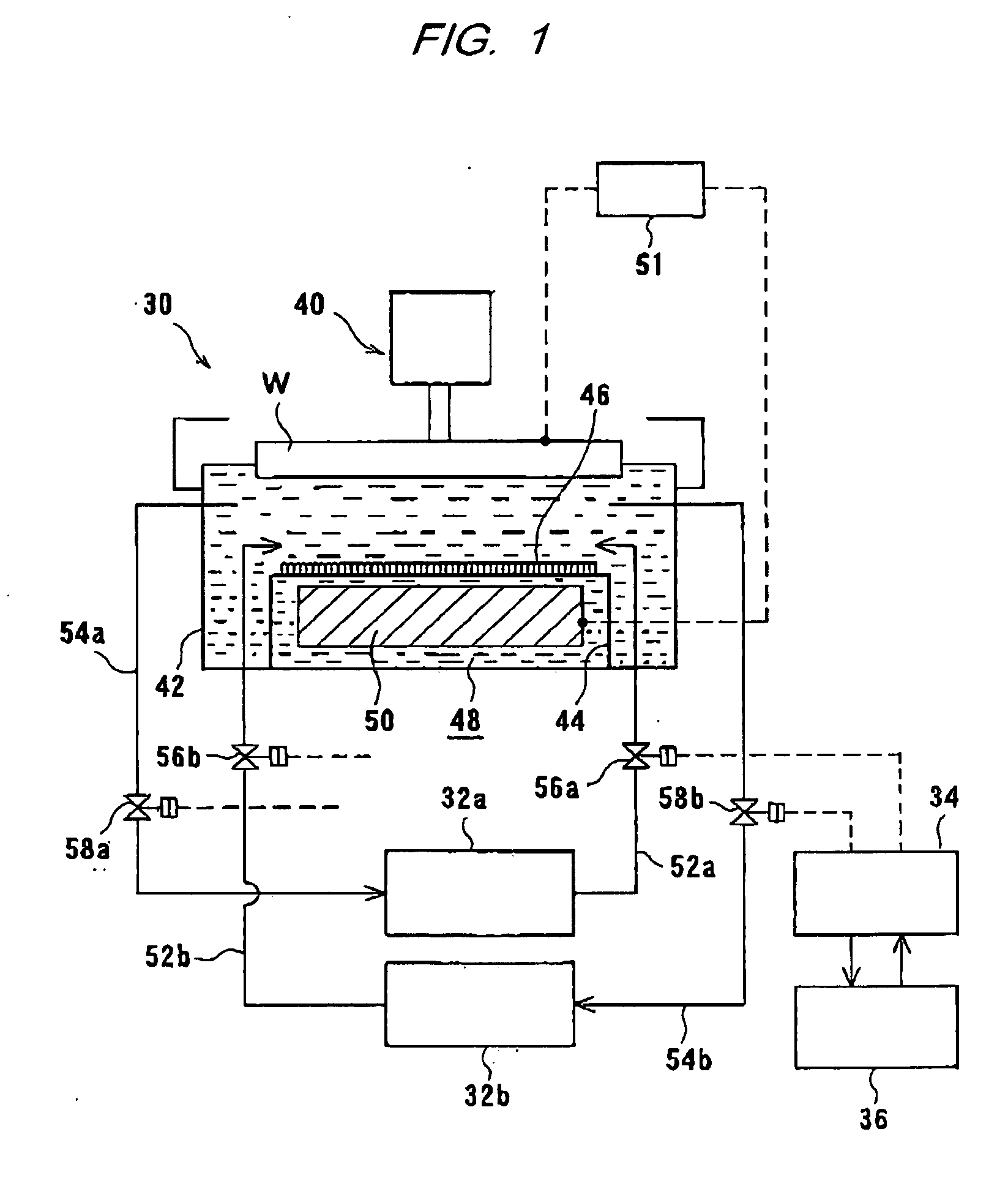

[0045]FIG. 1 is a schematic cross-sectional view of an electroplating apparatus (electrolytic processing apparatus) according to an embodiment of the present invention. As shown in FIG. 1, this electroplating apparatus includes an electroplating unit 30, two plating solution supply facilities (electrolysis solution supply facilities) 32a, 32b for supplying plating solutions as electrolysis solutions to the electroplating unit 30 and recover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| widths | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com