Method and machine for treating textile materials by ammonia or other liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

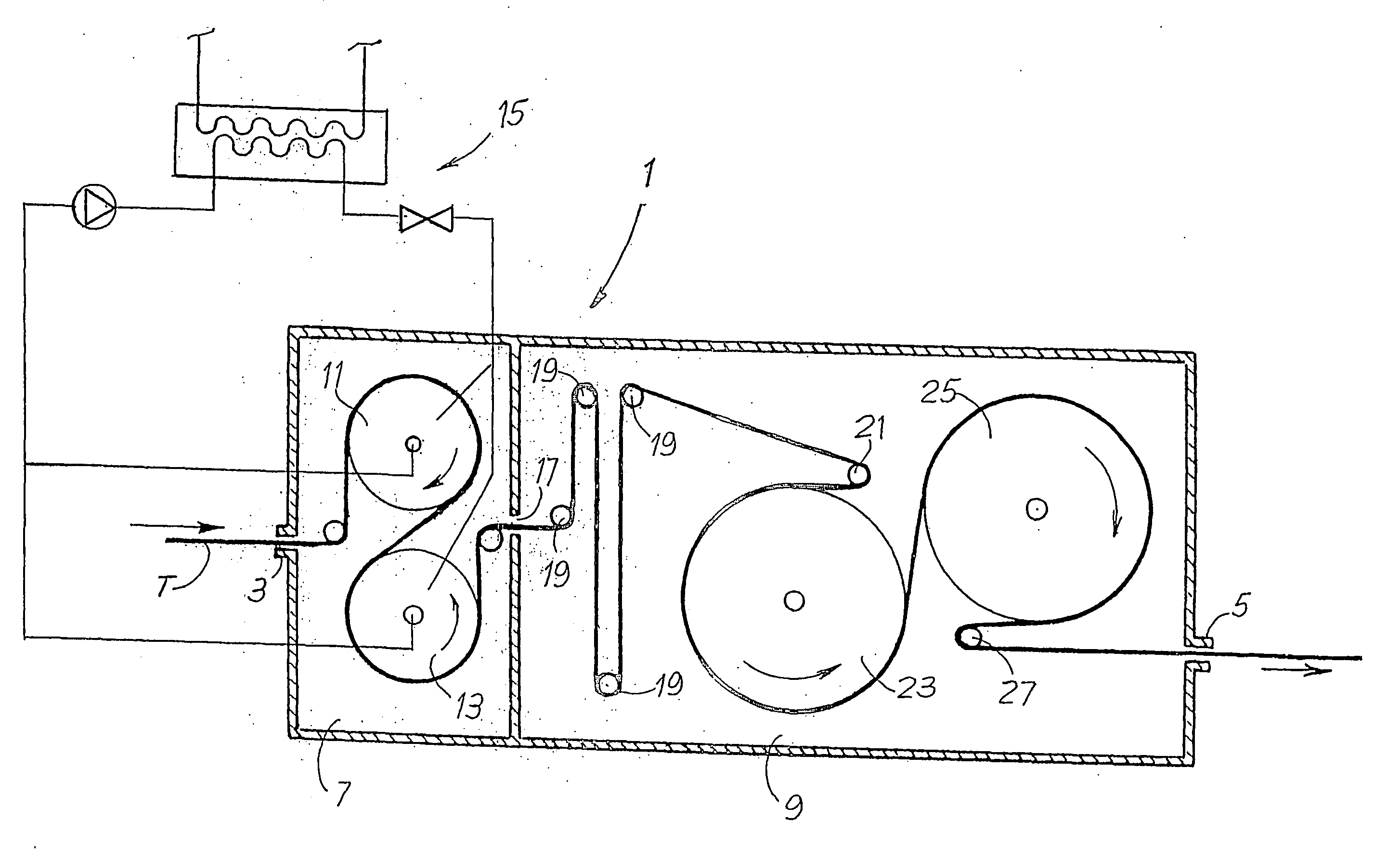

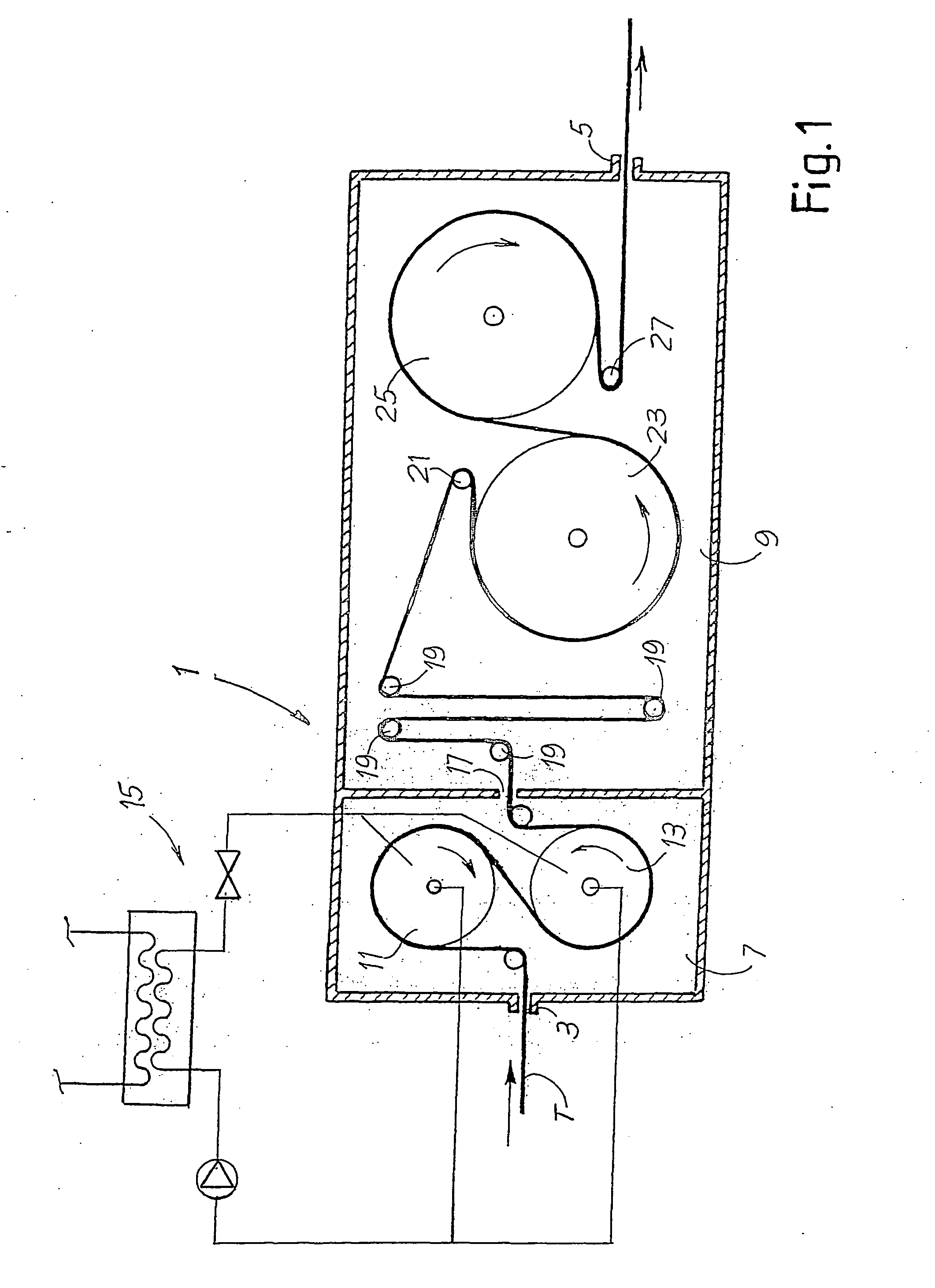

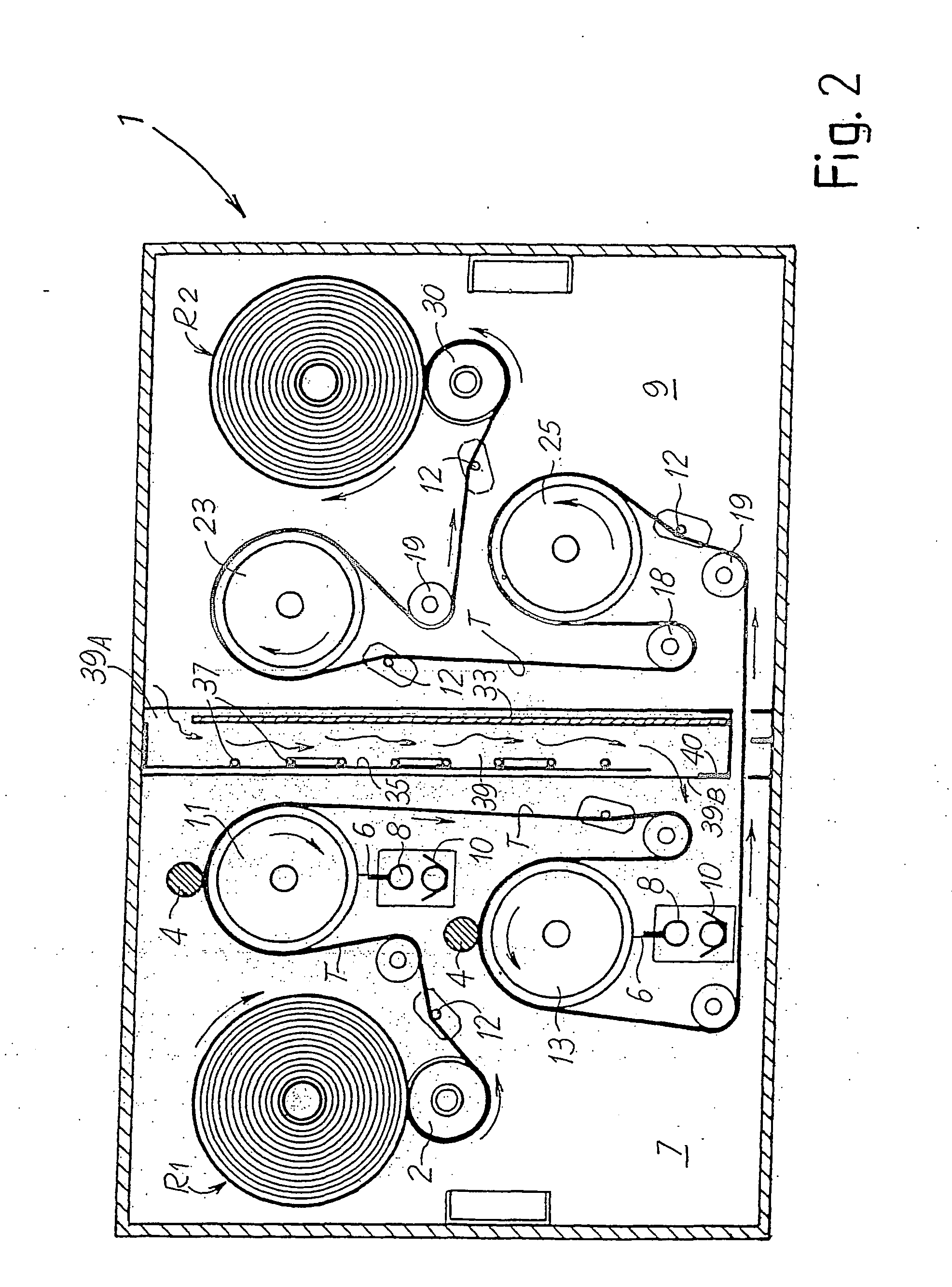

[0038] In the diagram in FIG. 1 the machine, indicated as a whole with 1, is of the continuous type and has an inlet 3 and an outlet 5 for the textile article, which in this example of embodiment is a fabric indicated with T. However, the treatment may also be performed on a yarn or on another type of textile article the fibers of which must undergo mercerization using ammonia. Means, of a per se known type (not shown), may be associated with the inlet 3 and the outlet 5, to prevent the gases present inside the machine from escaping.

[0039] Schematically the machine is provided with a first condensation or impregnation chamber, that is for the actual treatment, indicated with 7, communicating with a second drying chamber 9. The path of the fabric T to be treated extends and travels through the two chambers.

[0040] Two rollers 11, 13 are disposed in the impregnation chamber 7 and rotate in opposite directions according to the arrows in the drawing. The rollers may be motorized to fac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com