Carburized and quenched member and method for production thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0047] As Example 1, results of experiments conducted to verify advantages of the present invention will be described.

[0048] Steels (Steel 11 to Steel 14) having chemical compositions shown in Table 1, after being melt-formed in an arc furnace, were hot-rolled into round bars having a diameter of 150 mm and a diameter of 32 mm. The round bars were normalized by keeping them at 925° C. for an hour and then air-cooling them.

[0049] Steel 11 and Steel 12 are steel grades having new compositions developed in the example. Steel 13 and Steel 14 are steel grades corresponding to case hardening steels SCM420 and SNCM 815 according to JIS.

[0050] Firstly, for each steel grade, a hardenability J was determined by conducting a Jominy end quenching method according to JIS: G0561.

[0051] Results are shown in Table 1. This characteristic is a characteristic of a raw material irrelevant to the production method described below.

TABLE 1SteelComponent element (wt %)gradeCSiMnSNiCrMoBTiMbAlNHardena...

example 2

[0087] In this example, steels indicated in Table 6 (Steels 21 to 24 and Steels 31 to 38) were melted and formed into ingots, which were bloom-rolled and bar-rolled to produce round bars of 70 mm in diameter.

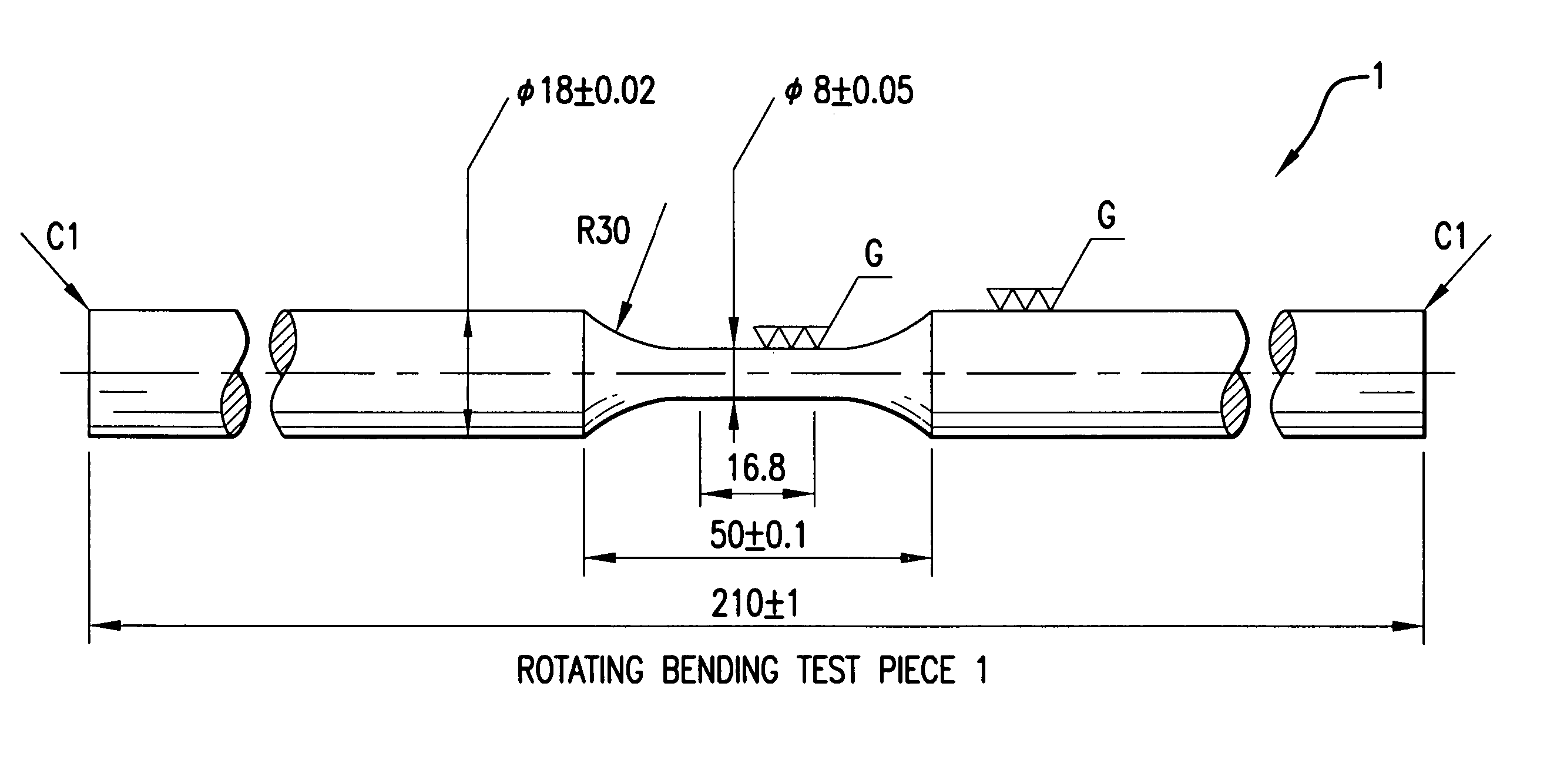

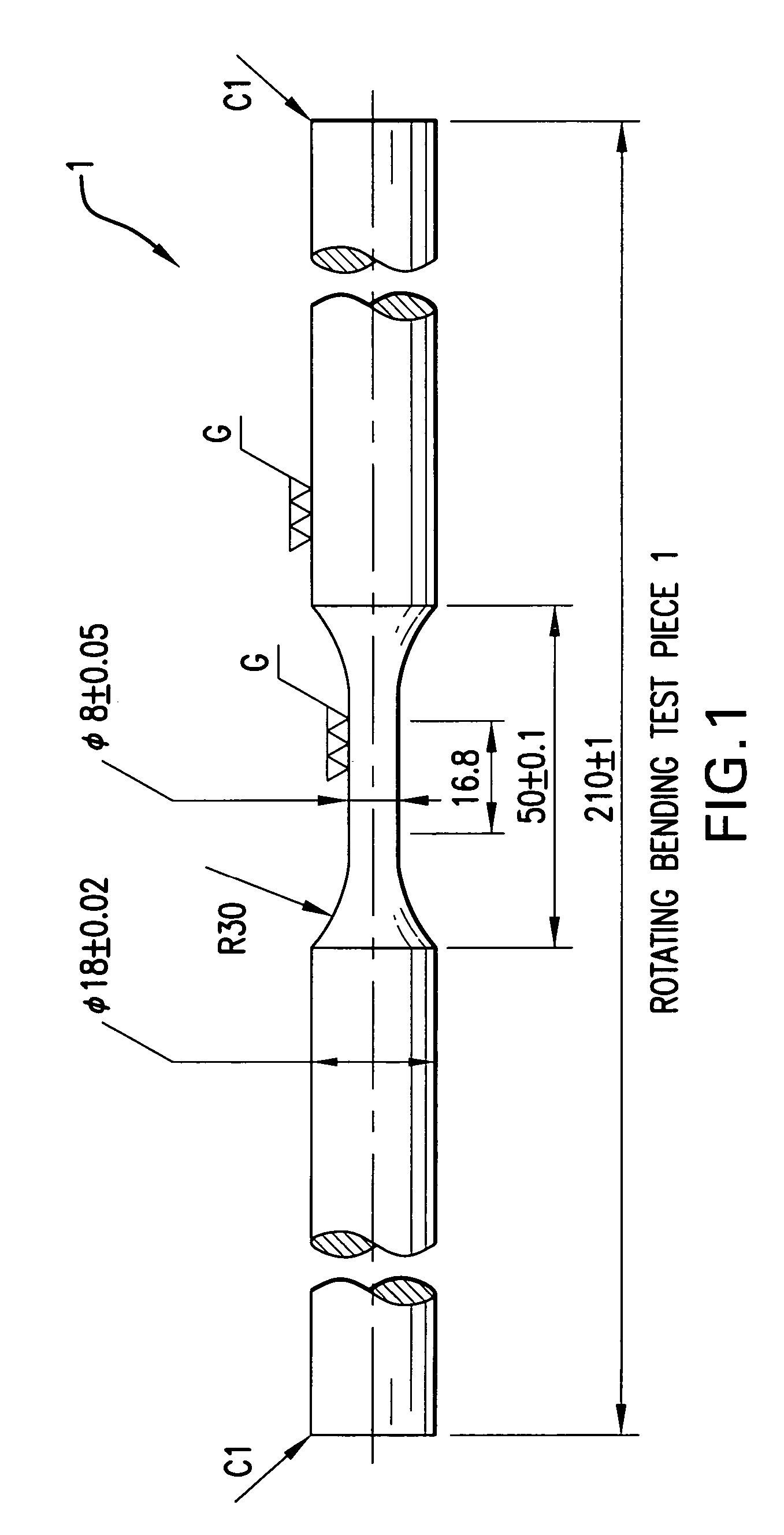

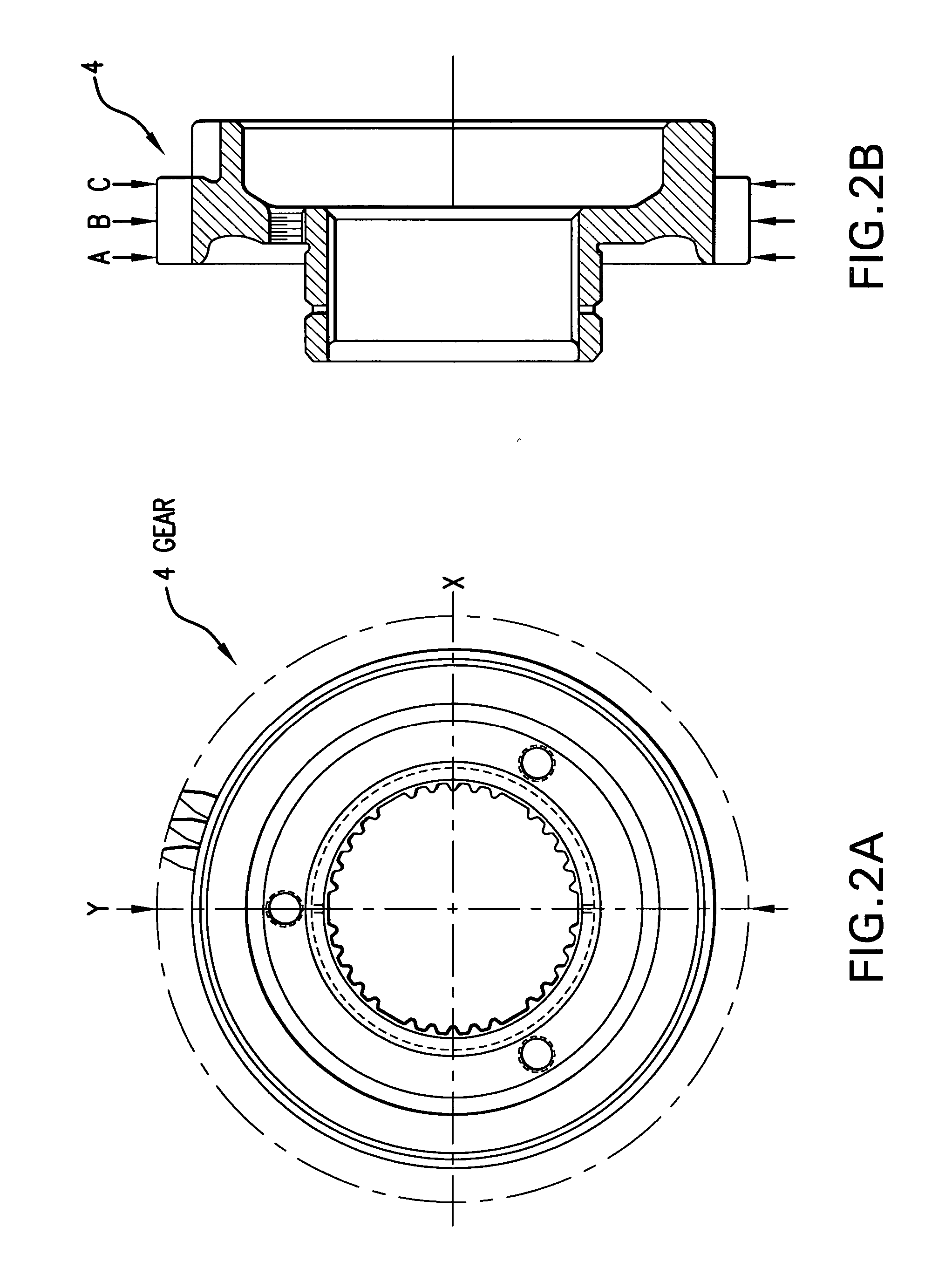

[0088] Subsequently, the round bars of 70 mmφ were stretched to 120 mmφ by hot forging. After being normalized at 925° C., the materials were formed into test pieces and toothed gears as in Example 1 (see FIGS. 1 and 2).

[0089] The test pieces and the gears were processed separately by three different production methods (Processes 3 to 5).

[0090]“Process 3” is characterized by gas carburization and oil quenching. In this process, steel is carburized and quenched and then tempered in a carburizing gas atmosphere in the manner of heating at 930° C. for 5 hours→diffusion at 850° C. for 1 hour→oil-quenching at 130° C.→tempering at 180° C. for 1 hour. The severity of quenching H in this case is 0.15 (cm−1).

[0091]“Process 4” is characterized by vacuum carburization and gas cooling. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com