Radon mitigation heater pipe

a heater pipe and radon technology, applied in the field of radon mitigation heater pipes, can solve the problems of reducing the service life of the heater pipe, and reducing the risk so as to reduce the risk of radon entering and accumulating inside the structure, and the effect of reducing the risk of failur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following detailed description is of the best presently contemplated mode of carrying out the invention. The description is not intended in a limiting sense, and is made solely for the purpose of illustrating the general principles of the invention. The various features and advantages of the present invention may be more readily understood with reference to the following detailed description taken in conjunction with the accompanying drawings.

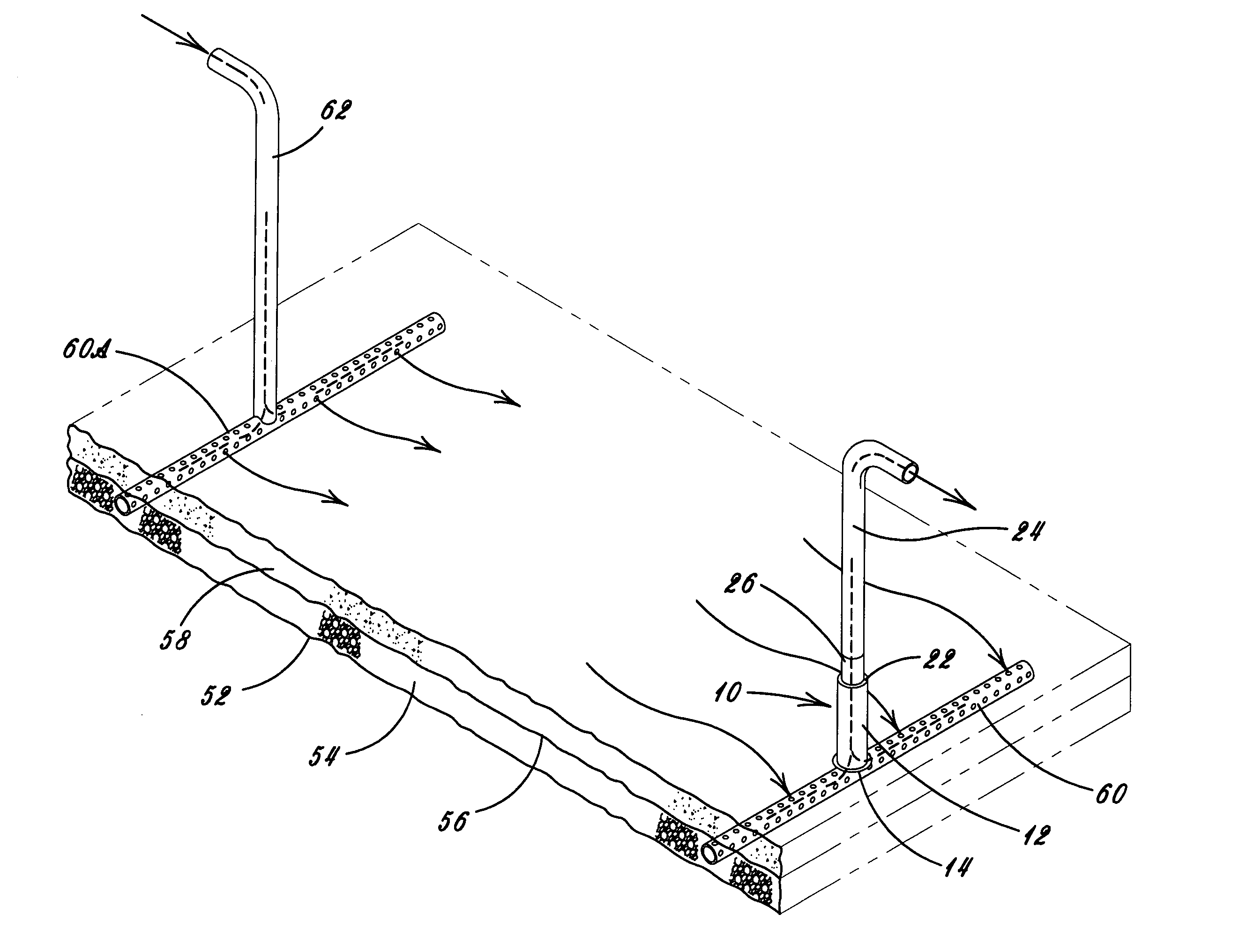

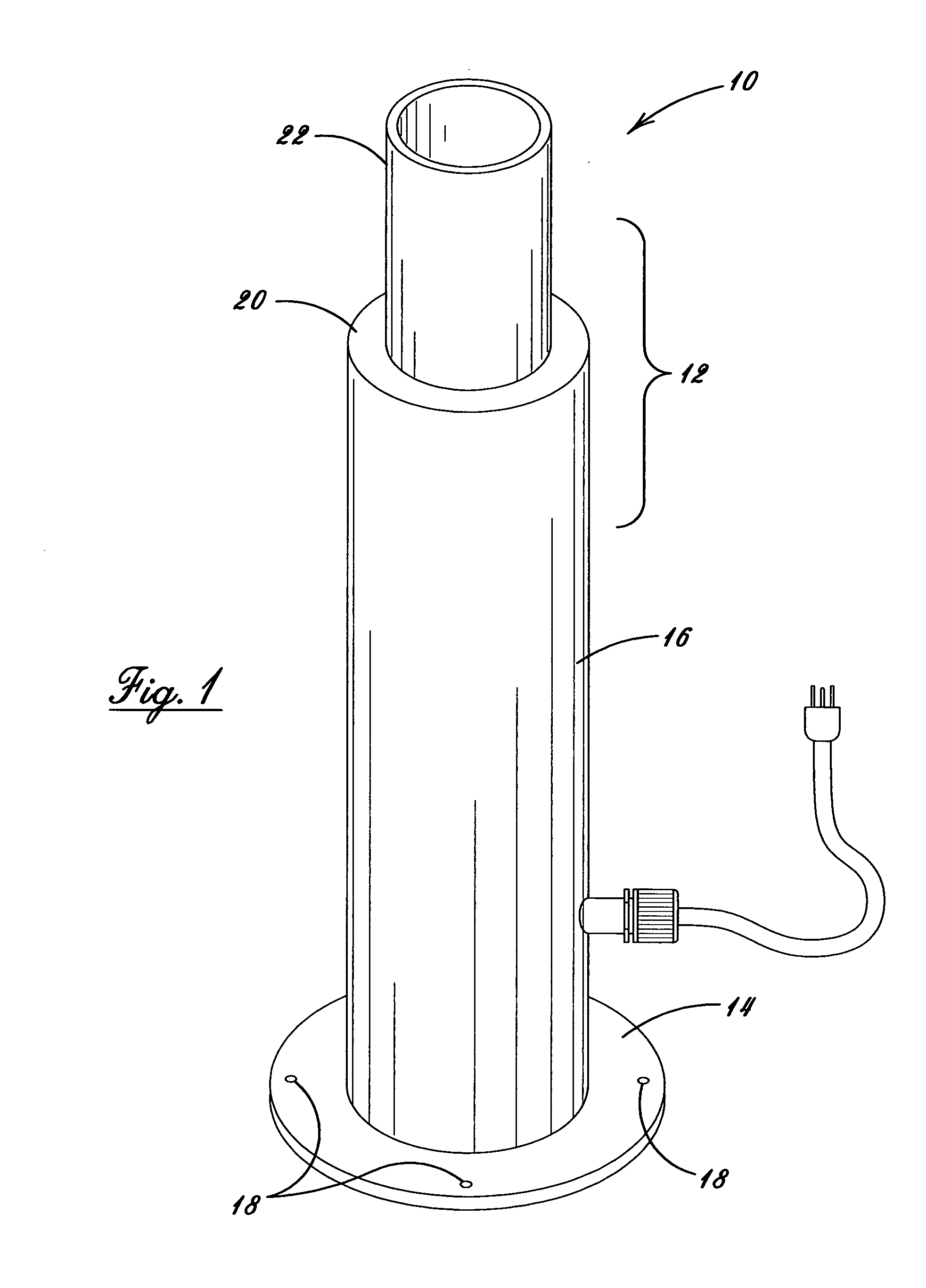

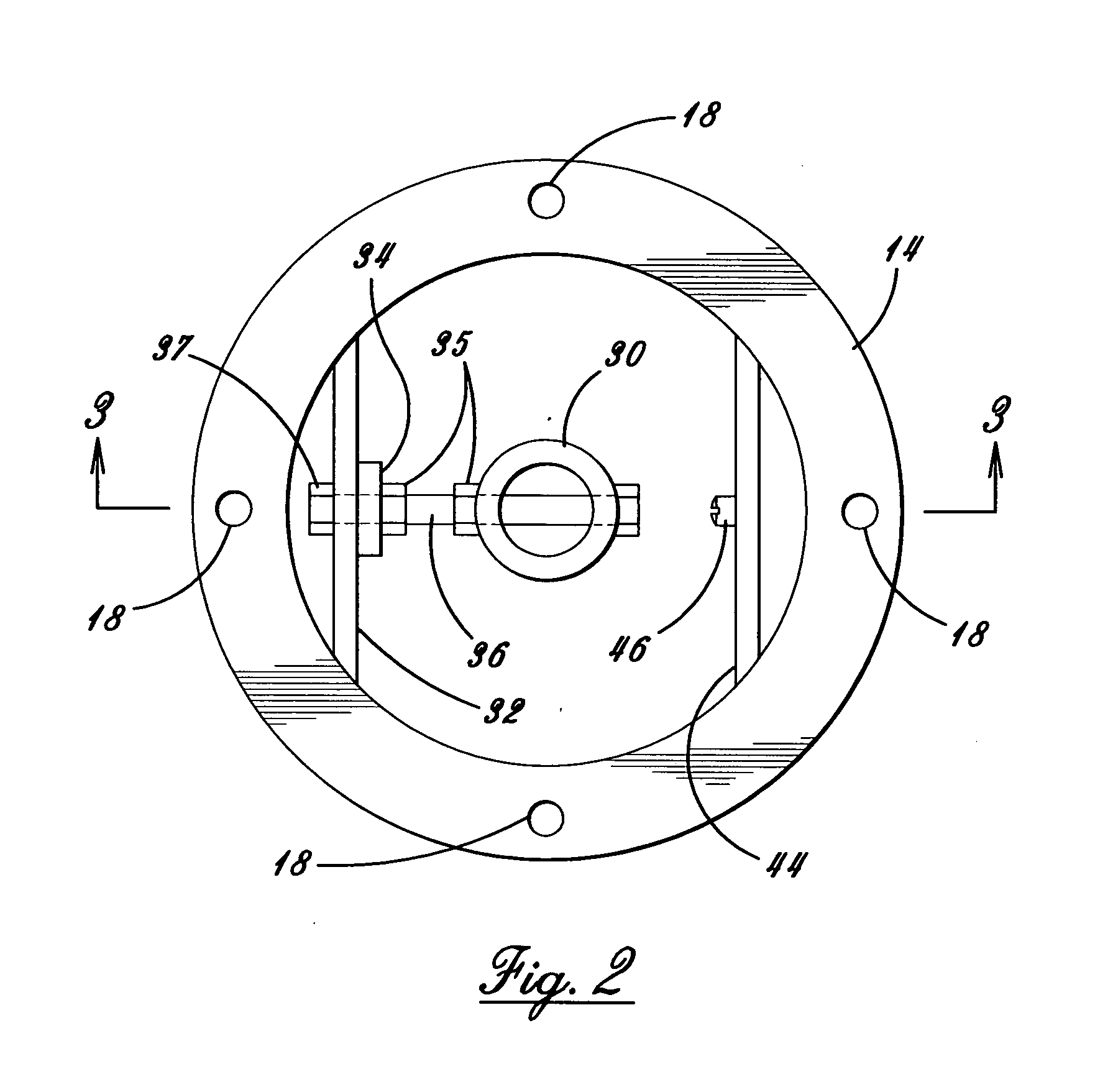

[0020] Referring now to the drawings in detail, where like numerals refer to like parts or elements, there is shown in FIG. 1 an exterior view of the radon mitigation device 10. The device is comprised of an external shell portion 12 and an internal heating portion 31.

[0021] The external shell portion 12 is fabricated by welding several components together; however a one-piece metal casting would be a preferable construction technique for a mass produced device. The base 14 is made from a round flat plate or flange having a central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com