Method for ignition of an oil burner and electronic ignition circuitry for oil burners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

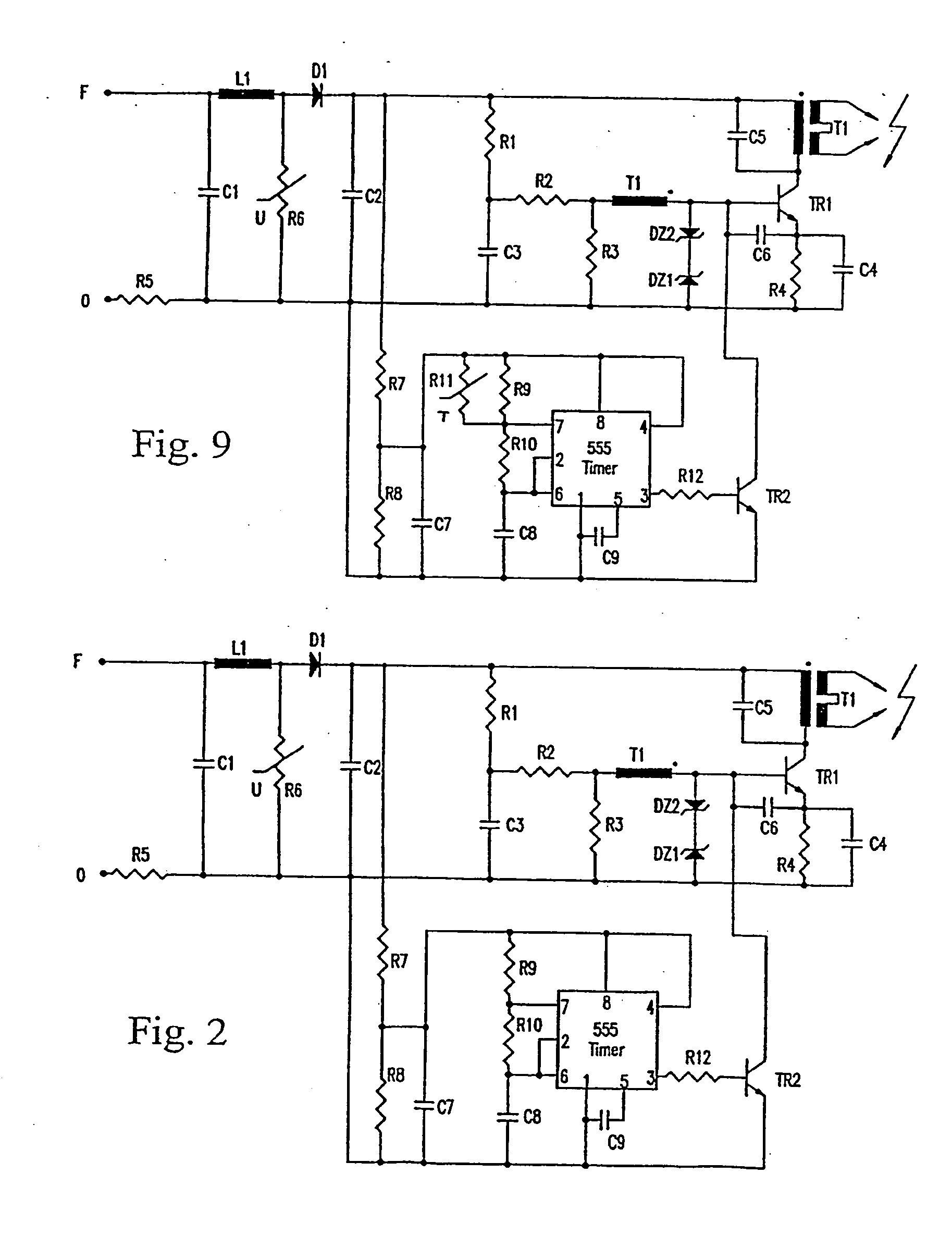

[0062] In a first embodiment, illustrated in FIG. 2, this is achieved by incorporating an on / off timer operating at a given duty cycle in the oscillator circuit.

[0063] The on / off timer is an astable timing circuit based on an integrated circuit commonly known as a 555 timer allowing a square signal with a given period to be output to the base of the transistor TR2. When the square signal is high the transistor TR2 conducts, thereby short circuiting the base of the transistor T1 to zero. Consequently the transistor TR1 is rendered non-conducting and thereby disables the oscillator circuit.

[0064] The on / off timer is supplied via a voltage divider R7, R8 with a smoothing capacitor C7 ensuring the supply of the timer between the voltage pulses from D1.

[0065] The 555 timer has two comparator inputs 6 and 7. During the time when the 555 timer is on the capacitor C8 is charged through the resistors R9 and R10. When the voltage difference between the inputs 6 and 7 falls below a predeterm...

second embodiment

[0081] According to the invention, illustrated in FIG. 3, the above resulting burst sequences may also be realised by means of electronic ignition circuitry comprising a combination of an on / off timer and the prior art circuit of FIG. 1. The timer is arranged so as to enable or disable the supply to the prior art ignition circuit. By interrupting the supply appropriately, some of the current supply pulses to the oscillator will be omitted and corresponding burst consequently not produced.

[0082] The timer could be replaced by a control box including a control circuit, which controls the overall operation of the burner system, where the control circuit enables and disables the supply to the prior art ignition circuit.

[0083] This has the advantage over the unit described above, that the prior art unit may still be used, and only supplemented with the timing circuit. The timing circuit may then have the same fixed values as described above, or it may be externally controllable to be sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com