Plasma processing apparatus

a processing apparatus and plasma technology, applied in the direction of electrical apparatus, plasma technique, electric discharge tubes, etc., can solve the problems of non-uniform circumferential (azimuthal) direction of reaction on the wafer surface, non-uniform circumferential direction of plasma, etc., to facilitate the determination process, enhance plasma processing performance and controllability of the apparatus as a whole, and facilitate the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

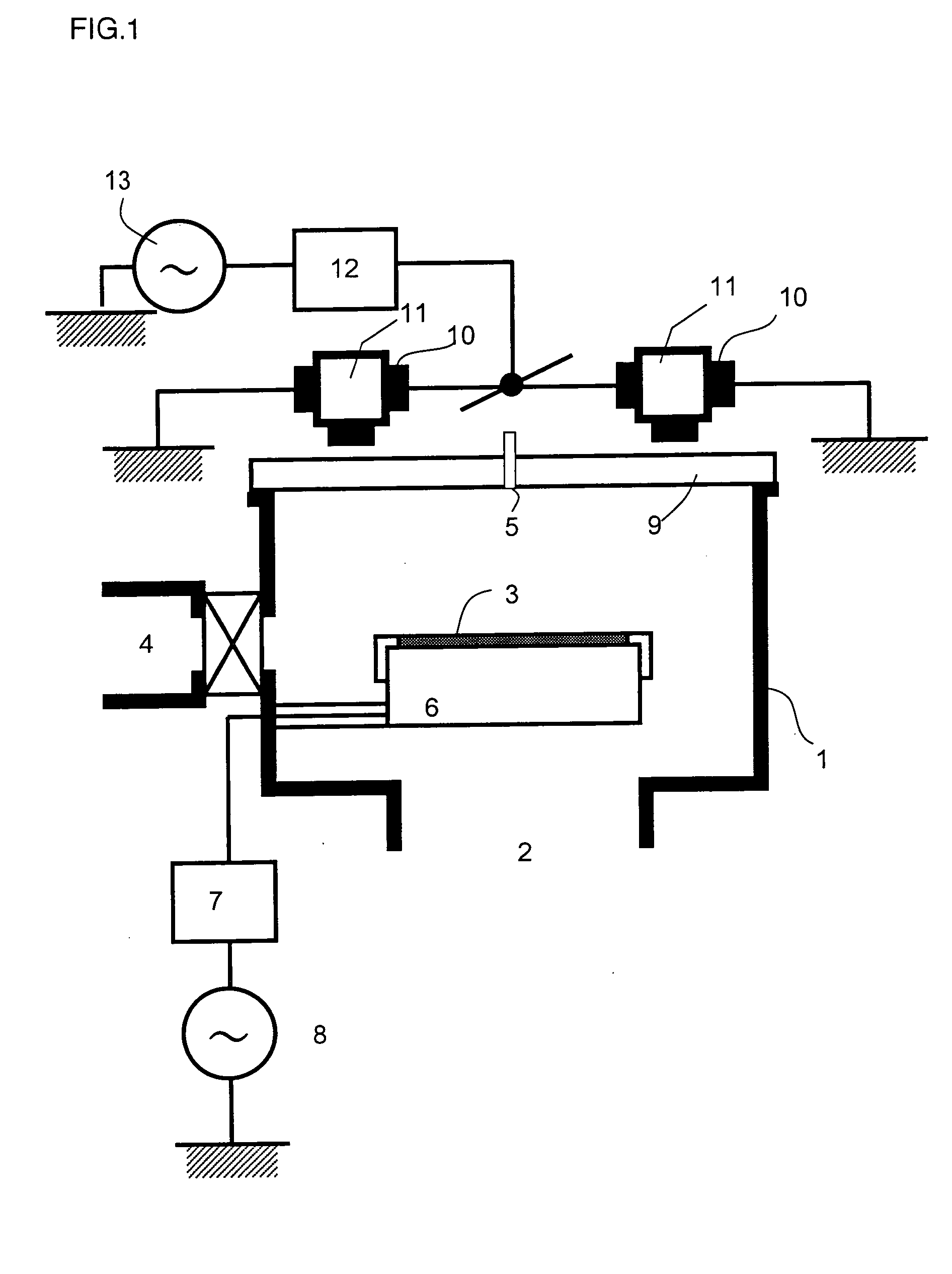

[0049] With reference to FIG. 1, an arrangement corresponding to a plasma processing apparatus according to the present invention will be described. An RF inductively coupled plasma processing apparatus comprises a processing chamber 1 maintained in vacuum, an evacuation means 2 connected to a vacuum pump for example for maintaining the interior of the processing chamber in vacuum, a wafer-transfer system 4 for carrying a semiconductor wafer 3 or object to be processed into and out of the vacuum processing chamber, an inlet 5 for introducing processing gas, an electrode 6 on which the semiconductor wafer 3 is placed (sample stage for mounting the object to be processed), a matching network 7, an RF power supply 8, an insulator 9 functioning as the ceiling of the processing chamber and through which the electric field created by radio frequency is introduced to the processing chamber, an RF induction coil 10 having an arrangement unique to the present invention, an annular insulating...

embodiment 3

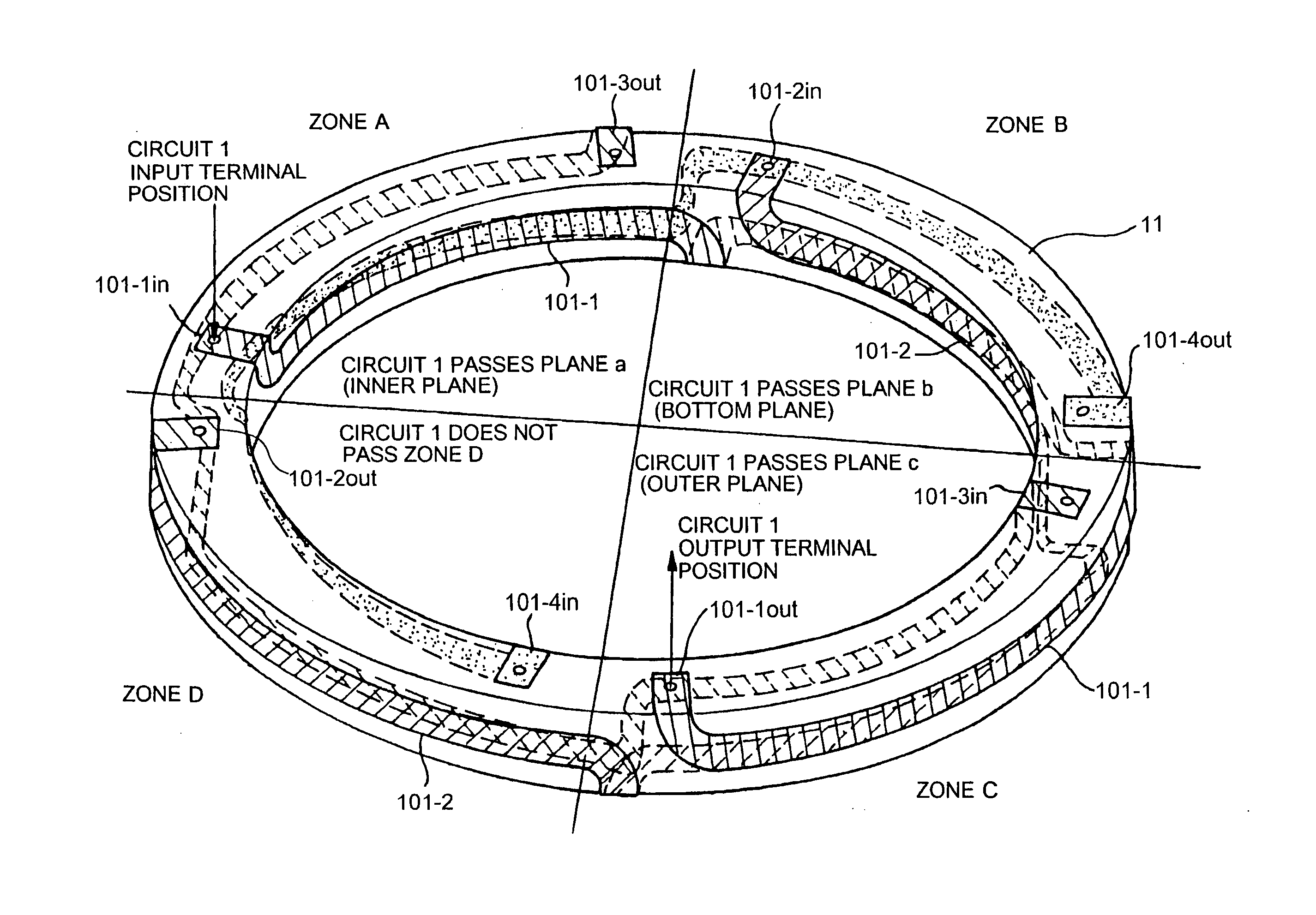

[0059] In this example, four circuits of ¾-turn coil elements are used, totaling in three turns. FIG. 6 is a perspective view showing the actual coil formed in this manner (embodiment 3). Unlike the example shown in FIG. 4 where the coil elements are disposed flatly, the present embodiment utilizes space advantageously and successfully creates a compact induction coil 10. By adopting this induction coil to the plasma processing apparatus illustrated in FIG. 1, it is possible to provide a plasma processing apparatus having advantageous circumferential plasma uniformity.

[0060] In the example of Table 1, each coil element is passed via adjacent planes, from plane a to plane b to plane c, but it is also possible to have the coil pass via plane a to plane c and then to plane b, as shown in Table 2. It may seem irrational to pass the coil from plane a directly to plane c, but since these planes are in confronting relations, the coil can be passed through a bore pierced through the insulat...

embodiment 7

[0064] In order to increase the number of turns, it may be possible to use an insulating ring 11 having a polygonal cross-section with more than four sides. This embodiment 7 will be illustrated with reference to FIG. 10 and table 6. The present embodiment uses an insulating ring 11 with an octagonal cross-section. The surfaces are denoted as planes a through h as illustrated, and through use of seven planes excluding the upper plane, plane h, coil loops are arranged in a manner similar to the embodiment of FIG. 5, wherein the coil element of circuit 1 is first disposed on plane a in zone A and extended via planes b, c, d, e, f and g transiting planes every 90°, and the coil element of circuit 2 is first disposed on plane a in zone B and extended via planes b, c, d, e, f and g transiting planes every 90°, thereby forming loops. A single coil element circuit constitutes 7 / 4 turns, so by disposing four circuits, the induction coil totals in seven turns.

TABLE 6Planes used: 7, 7 / 4-turn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radio frequency | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com