Aging method for plasma display panel

a plasma display panel and aging method technology, applied in the manufacture of electrode systems, electric discharge tubes/lamps, tube/lamp factory adjustment, etc., can solve the problems of reducing the yield of products, changing the aging characteristic, and reducing the storage of charges, so as to prevent the variation of the aging characteristic and reduce the storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

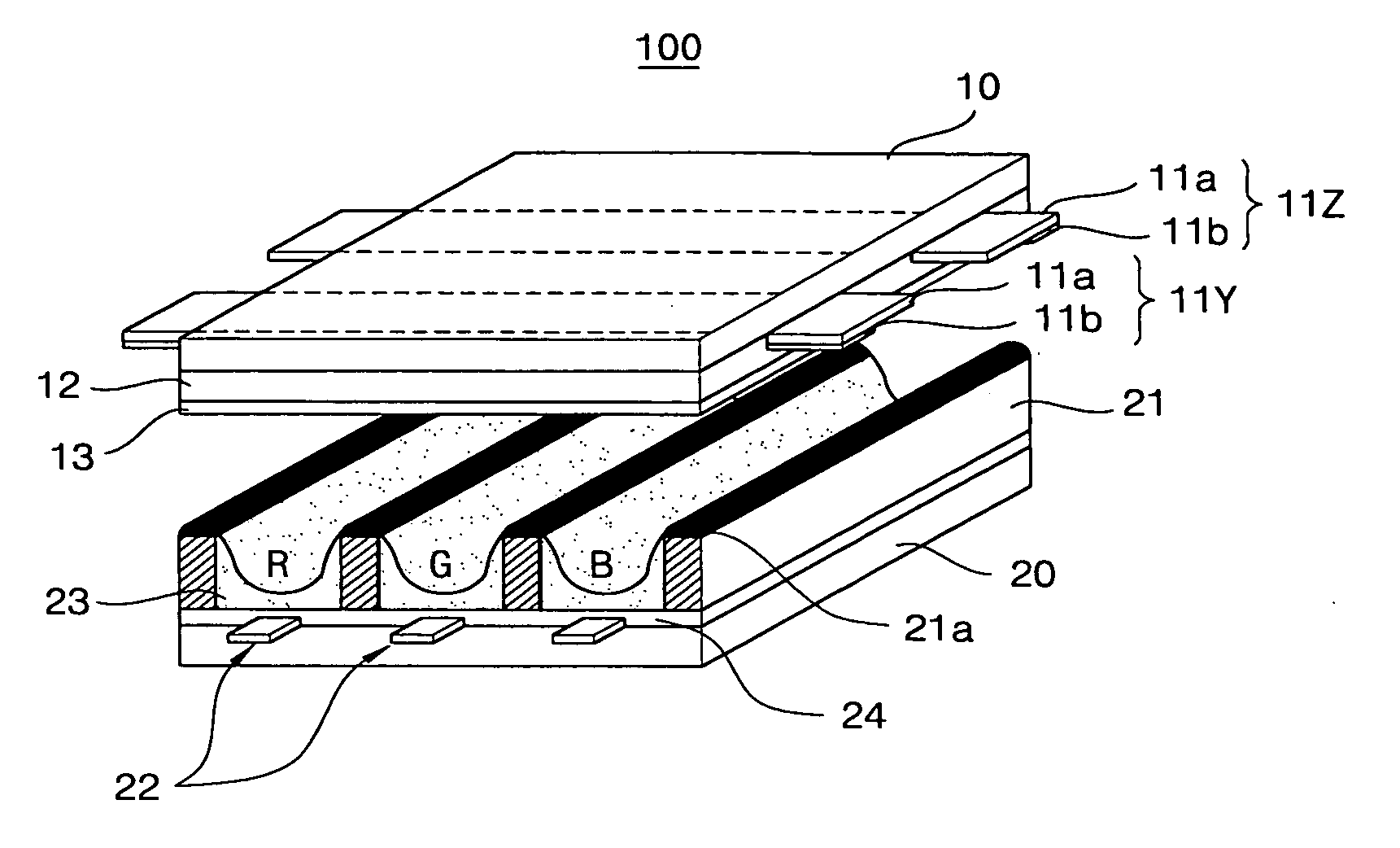

[0032] Preferred embodiments of the present invention will be described in a more detailed manner with reference to the drawings.

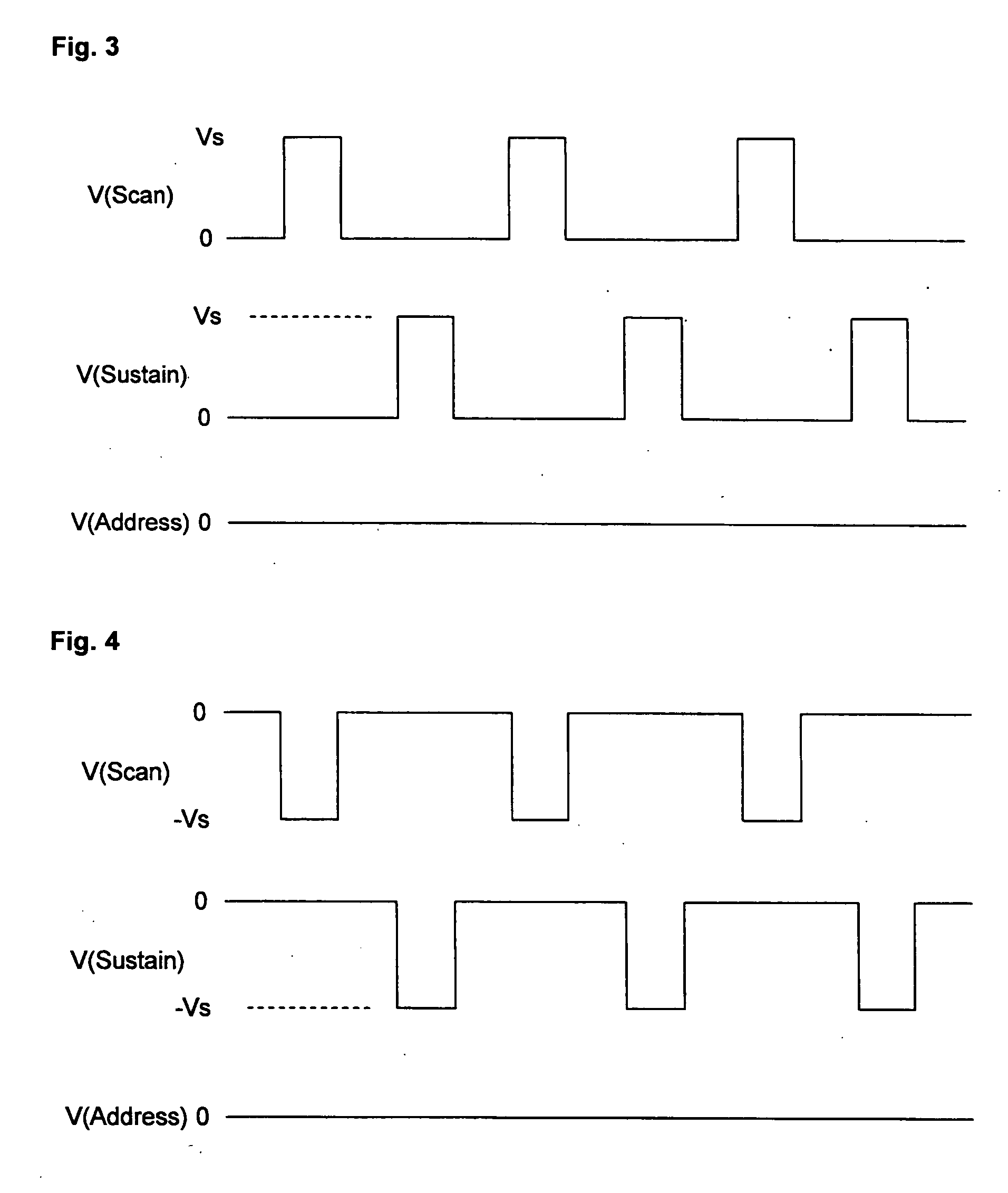

[0033]FIG. 4 is a waveform diagram illustrating a sustain discharge pulse applied in an aging method according to an embodiment of present invention.

[0034] As shown in FIG. 4, the alternating sustain discharge pulse is applied to a scan electrode and a sustain electrode. The sustain discharge pulse has a reference voltage of 0V, and has a discharge voltage of −Vs lower than the reference voltage. The same voltage as the reference voltage (0V) is continuously applied to the address electrode.

[0035] As the voltages are applied, positive ions move to a magnesium oxide (MgO) layer of a front panel due to the scan electrode and the sustain electrode having a lower voltage than the address electrode. Since the MgO layer of the front panel has a larger secondary electron emission coefficient than a phosphor layer of a rear panel, the front panel emits more sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com