Coatings comprising carbon nanotubes and methods for forming same

a technology of carbon nanotubes and coatings, applied in the direction of conductive layers on insulating supports, non-metal conductors, conductors, etc., can solve the problems of poor productivity, complicated apparatus having vacuum systems, difficult to apply to continuous or big substrates such as photographic films or show windows, etc., to reduce manufacturing costs and increase product effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

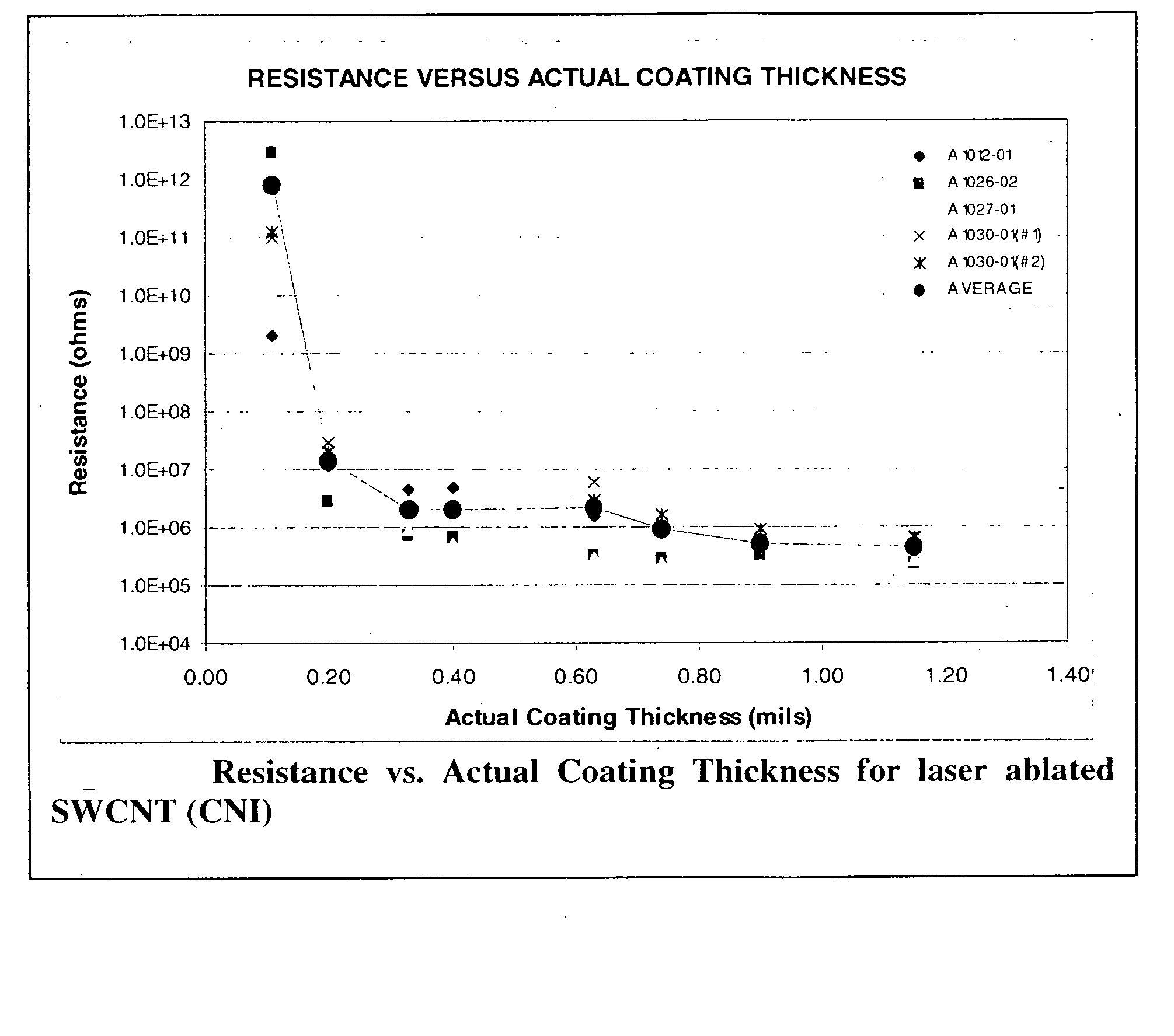

[0064] Comparison of Electrical Properties for MWNT (Hyperion and Carbolex) and SWNT (CNI (Laser Ablated and HiPCO))

[0065] The nanotubes in Table 1 were sonicated for eight minutes into Titanium SI-DETA (ceramer hybrid resin, this work has been repeated for other resin systems like epoxy and urethane) and then cast onto a glass or polycarbonate slide. A set of Hyperion MWNT was sonicated in toluene then rinsed in IPA and added to the Titanium SI-DETA were it was sonicated for another 4 minutes. The thickness of the cast films is 0.5 mils thick.

TABLE 1HyperionWt. %MWnT% TBuckyNanotubesHyperionTolueneTolueneUSACNIDry Wt.MWnT% TExtractedExtractedMWnT*% TSWnT% T0.042.2E+984.50.063.5E+773.50.083.5E+776.20.10>1.0E+1192>1.0E+1185.5>1.0E+1194.44.5E+780.20.20>1.0E+1188.1>1.0E+1177.4>1.0E+1194.21.0E+770.00.30>1.0E+1188.7>1.0E+1174.1>1.0E+1193.17.5E+659.410.40>1.0E+1185.7>1.0E+1192.51.7E+654.80.50>1.0E+1182.2>1.0E+1163.4>1.0E+11921.00>1.0E+1168.53.5E+937.5>1.0E+1184.72.00>1.0E+1146.96.0E+61...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com