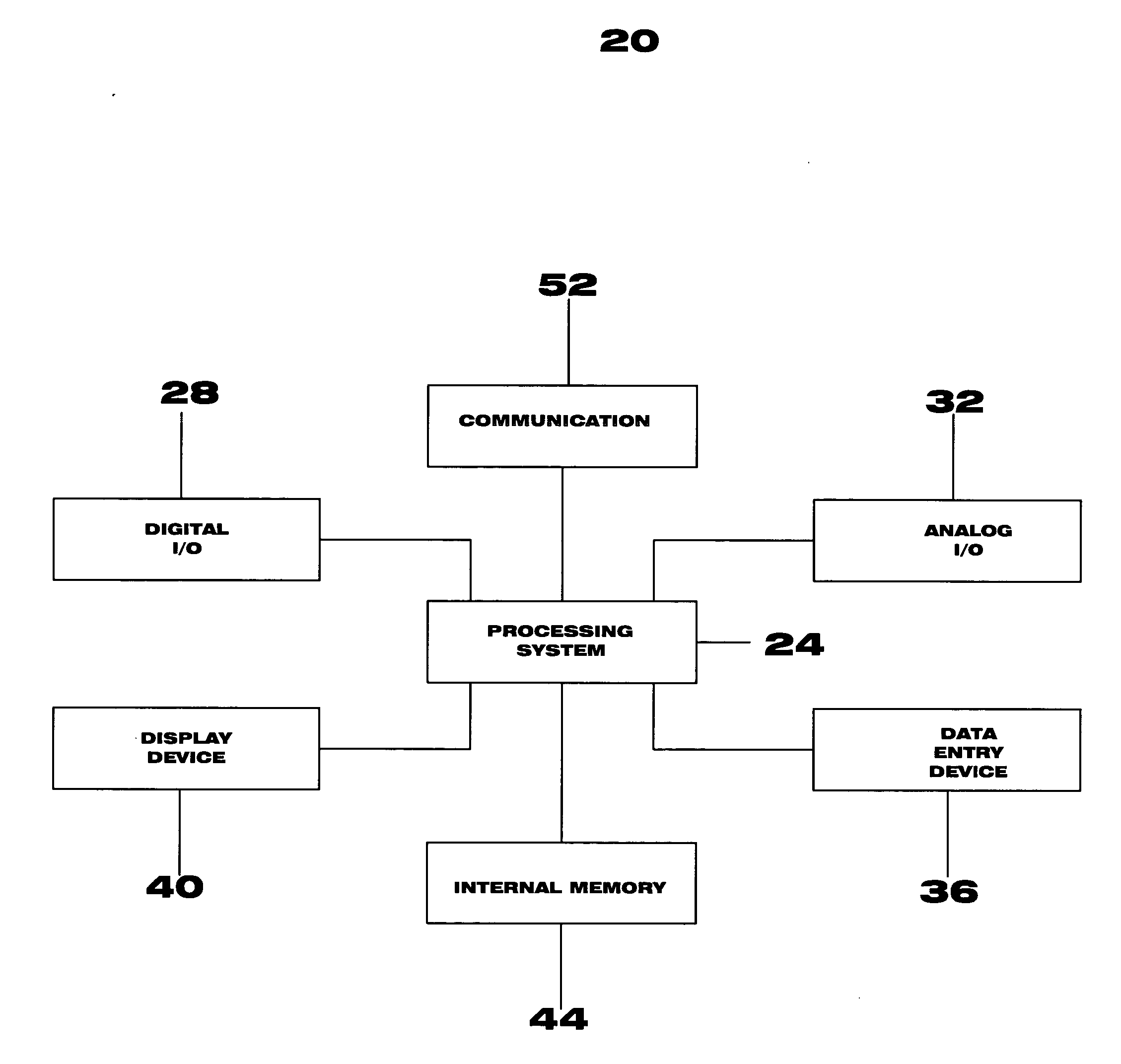

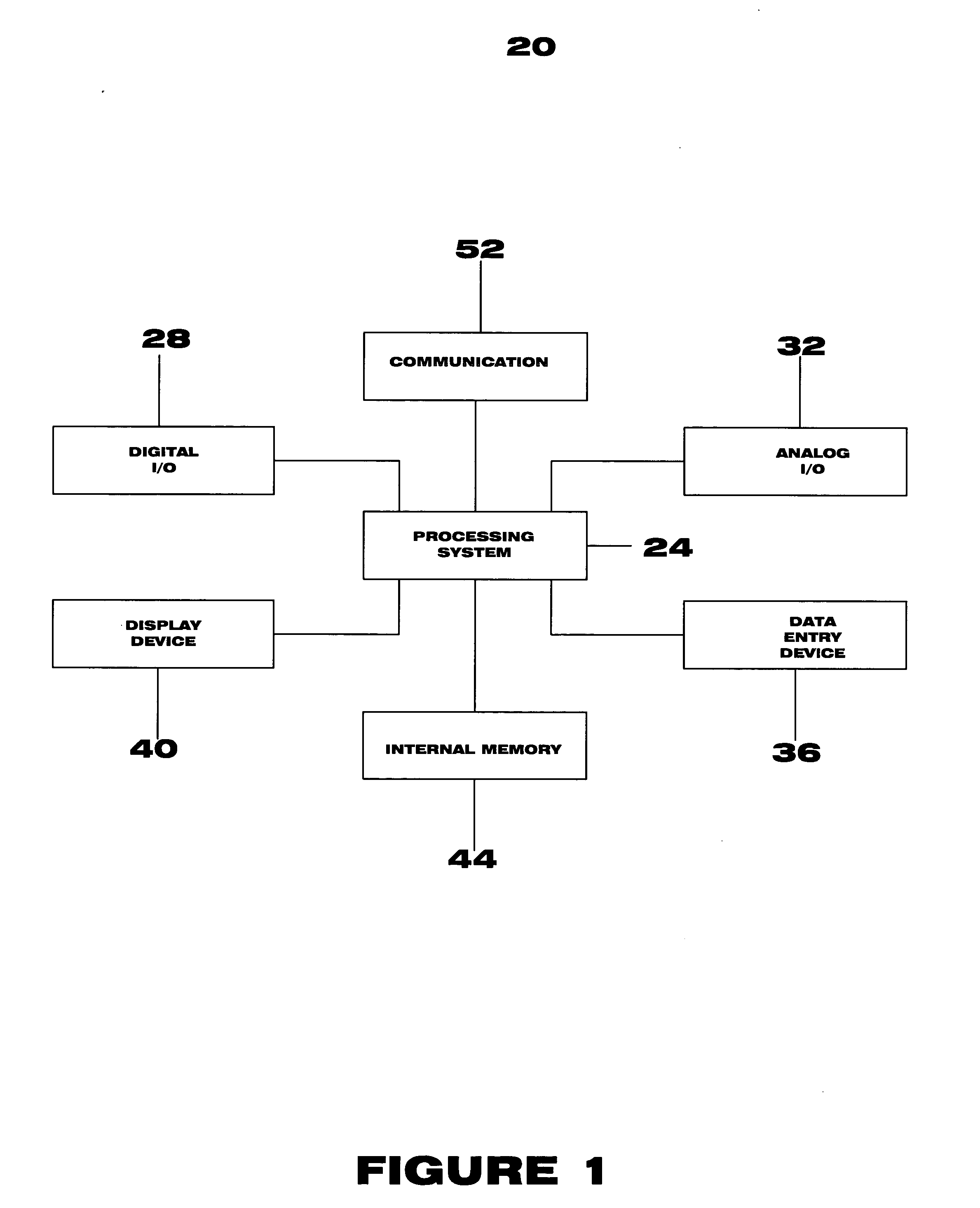

[0013] The

system and method for industrial

process control is a superior

system and method for controlling an industrial process. A

microcontroller is mounted atop a

printed circuit board optimally configured to minimize the system's

footprint to conserve space. The system further incorporates a plurality of inputs and outputs a compact

data entry device, a data viewing device, memory and communication capabilities and

modular software. The

software is modular in that the low level drivers that interface the hardware to the processor are written in

machine language whereas the interface between the process and the operator is written in a high level language, such as C++, to facilitate and expedite

reprogramming of the controller to revised parameters or even to a totally new application.

[0014] Industrial processes are becoming more complex requiring greater precision, regular quality improvements and less waste in order for the process owner to survive in the increasingly competitive global marketplace. Few industries can survive without automating their processes and minimizing the amount of human oversight because of the increasing portion of revenue that is consumed by personnel costs. Moreover, human oversight of

industrial systems generally cannot compare with the quality provided by automated systems.

[0016] Programmable logic controllers are many times the preferred choice for process control. Programmable logic controllers; however, frequently lack sufficient capabilities to control a robust process with sophisticated oversight requirements unless additional input / output (I / O) control hardware and feedback capabilities are purchased thereby increasing the cost of process

automation. Also, maintenance costs can increase substantially whenever a

programmable logic controller system malfunction occurs because not only must the controller be checked for component failures, but the supplemental I / O hardware, transducers and devices being controlled must be either thoroughly examined, thereby incurring additional maintenance and

downtime costs, or quickly replaced in order to bring the

production line back to full capacity, thereby drastically increasing hardware costs.

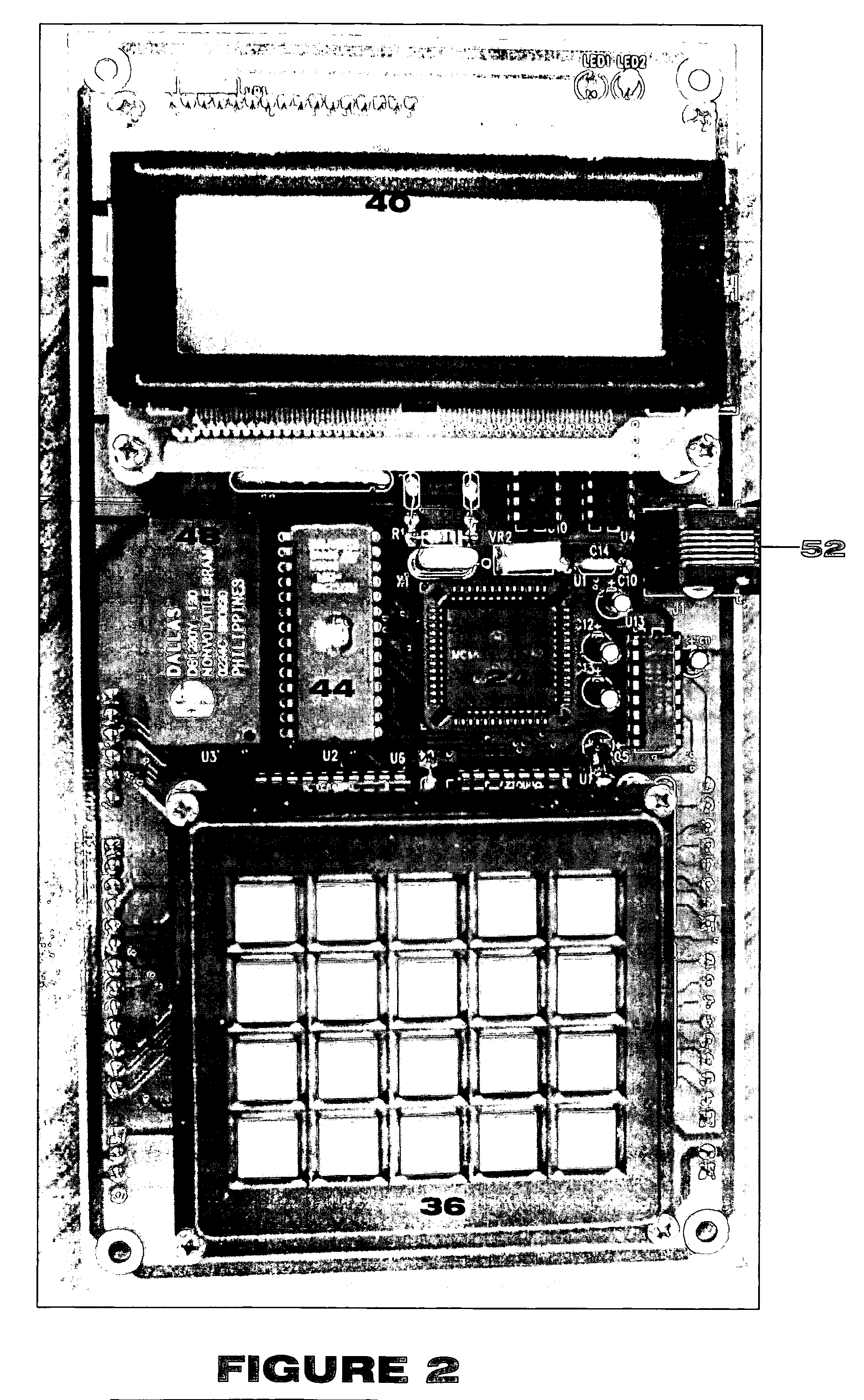

[0018] The process

control system of the present invention is compact and can readily be mounted in close proximity to the process being controlled and can also be mounted in a hardened

enclosure to protect the componentry. The close proximity of the controller to the process being controlled gives the process operator an

advantage when

reprogramming process parameters. The operator can enter data using the

data entry device such as a keypad and then view the data subsequent to entry to confirm its accuracy on the

display device such as an LCD screen. Once the data is entered and confirmed by the operator, the production process can be initiated and viewed by the operator in close proximity to the process to witness the updated operation and confirm

process operation is as desired.

[0019] The system and method for industrial process control utilizes modular

software wherein the low level drivers that interface the

system hardware to the processor are written in

machine language. The software controlling the interface between the application itself and the user, however, is written in a higher level

programming language. Additionally, the process

control system will have predefined software interfaces with the

display device and the

data entry device also jointly referred to as the

human machine interface. The predefined software interface is created with the development of a new status screen on the

data display device.

Display device screens are linked to predefined text and parameters that are to be displayed thereby greatly improving the functionality of the system in regards to updating process application parameters.

[0020] Process applications requiring robust

closed loop control capabilities such as the ability to control

servo motors will typically be unable to rely upon programmable logic controllers to accomplish the task without the addition of feedback capabilities that will increase the overall cost. A process controller relying upon a

microcontroller and possessing the functionality outlined herein will be critical to the success of such an application and the system and method for industrial process control outlined herein will further improve overall production capabilities.

Login to View More

Login to View More  Login to View More

Login to View More