Gel having biosubstance fixed thereto and microarray utilizing the gel

a biosubstance and gel technology, applied in the field of biosubstance-immobilized gel and biological substance-immobilized gel microarray, can solve the problems of lower fluorescence intensity in the center region and higher in the outer region of the compartment, and achieve the effect of high hybridization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(1) Production of Polymethylmethacrylate (PMMA) Hollow Fibers

[0057] An acrylic resin with a mass molecular weight of about 90,000, which was composed of methyl methacrylate (MMA) and methyl acrylate (MA) in a monomer ratio of 82:18, was used as a source material and melt-extruded using an extruder through a spinning nozzle having a circular outlet, thereby obtaining hollow fibers with an outer diameter of 0.3 mm, an inner diameter of 0.2 mm and a length of 600 mm.

(2) Production of a Hollow Fiber Alignment

[0058] Two perforated plates of 0.1 mm thickness were placed one upon another, each of which had 9 holes (diameter: 0.32 mm; center-to-center distance: 0.42 mm) arranged in a 3 by 3 array, and 9 hollow fibers prepared above were then threaded through the respective holes in these perforated plates. The space between these two perforated plates was set to 50 mm and the hollow fibers were fixed under tension at two points, 50 mm and 100 mm from one end.

[0059] A resin raw materia...

example 2

[0085] The same procedure as used in Example 1 was repeated to prepare slices, except that monomer solution A and capture probe A were replaced by monomer solution D and capture probe B (SEQ ID NO: 5), respectively. Capture probe B was constructed to have a terminal methacrylate group by introducing an amino group at the 5′-terminus and then reacting the same with glycidyl methacrylate.

[Monomer Solution D]

[0086] Dimethylacrylamide (0.27 g) and methylenebisacrylamide (0.03 g) were dissolved in a 50 / 50 (by mass) mixture of glycerine and pure water to give a total volume of 10 ml.

[Capture probe B (SEQ ID NO: 5)]aaatacgcct gcaggcggag atcttccagg cccgcctcaagggctggttc gagccaatag tggaagacat

[0087] Hybridization and washing were performed as follows.

(1) Hybridization

[0088] A hybridization solution was prepared, which was supplemented with 1 pmol / ml oligonucleotide E (SEQ ID NO: 6) including, as a part thereof, a complementary sequence to the nucleotide sequence of capture probe B (nucl...

example 3

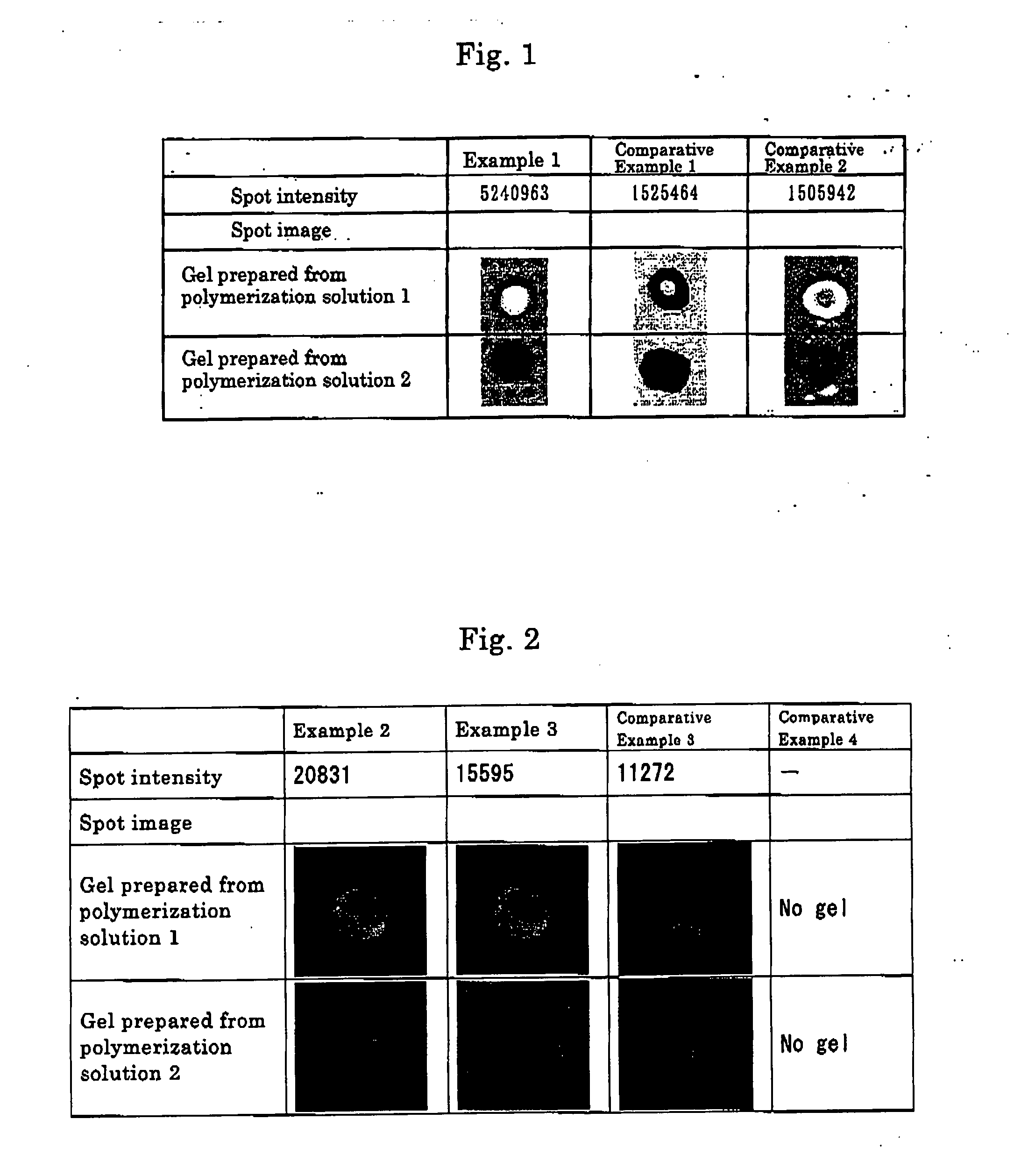

[0096] The same procedure as used in Example 2 was repeated, except that monomer solution D was replaced by monomer solution A. FIG. 2 shows the fluorescence intensity per compartment, along with an image of the washed hollow fiber and its surrounding area. The center of each compartment was determined as appropriate. As a result, the distribution of fluorescence intensity in the hybridized compartments was uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com