Brittle material fine particles with internal strain for use in aerosol deposition method

a technology of brittle material and fine particles, which is applied in the direction of transportation and packaging, coatings, chemistry apparatuses and processes, etc., can solve problems such as weak impact resistance, and achieve the effect of increasing the effect and removing the cohesion factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

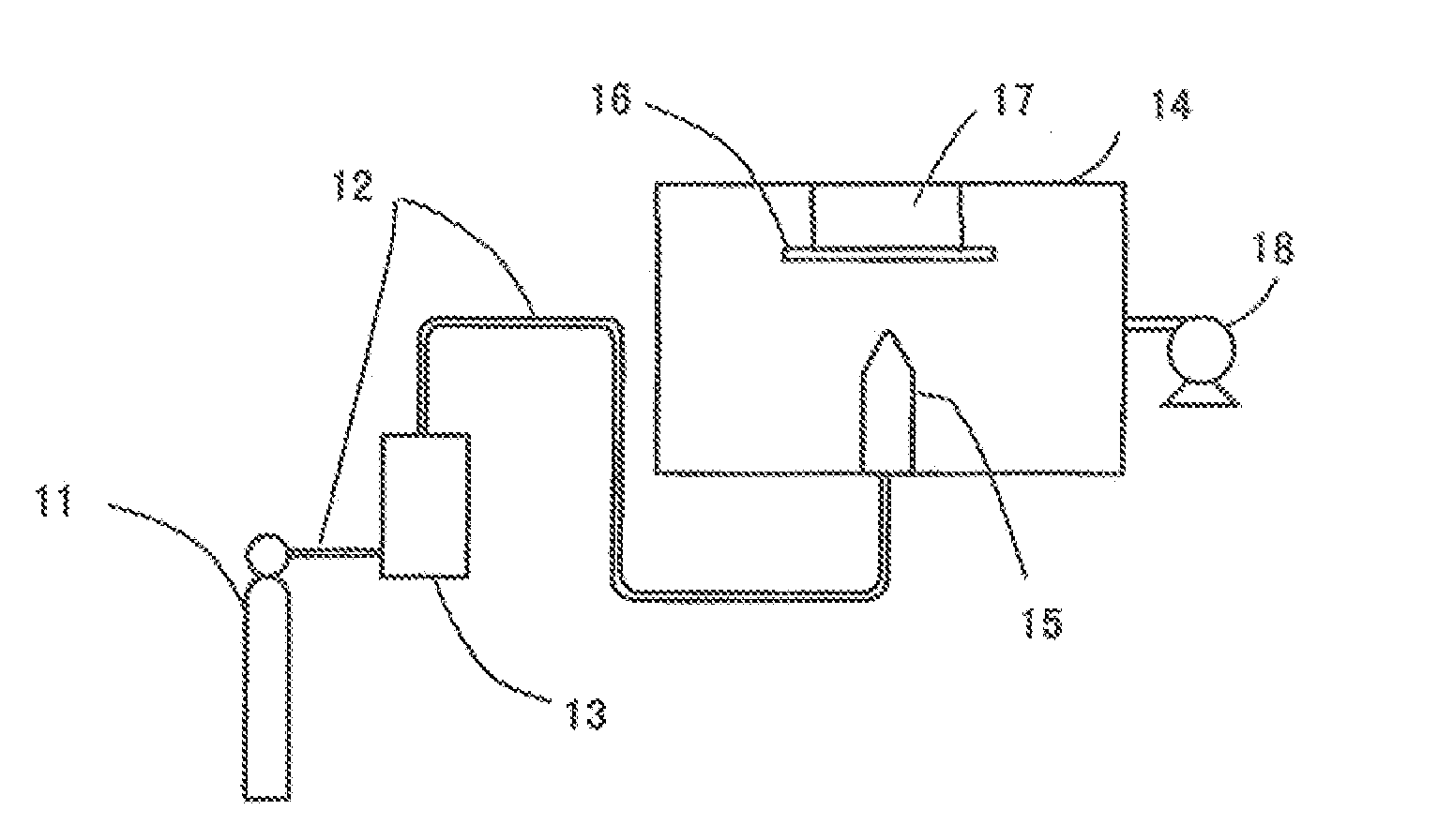

[0109]FIG. 1 is a view showing a first embodiment of a composite structure forming apparatus. A helium gas cylinder 11 is connected to an aerosol generator 13 through a carrier pipe 12 and a nozzle 15 with a rectangular opening of 5 mm×0.5 mm is disposed within a structure-forming chamber 14 through the carrier pipe. A tabular substrate 16 made of metal aluminum (Al) is mounted facing the nozzle on a substrate holder 17 which is controllable by a computer vertically (Z) and longitudinally and laterally (XY) 10 mm from the nozzle 15. The structure-forming chamber 14 is connected to an exhaust pump 18.

[0110] In the present invention, since raw fine particles with internal strain are used, a planetary grinder or a mill serving as pre-treatment equipment for imparting the internal strain to the raw fine particles is arranged next to the aerosol generator 13 or the like. However, it is also possible to convey the raw fine particles that have been pre-treated in a different location to b...

second embodiment

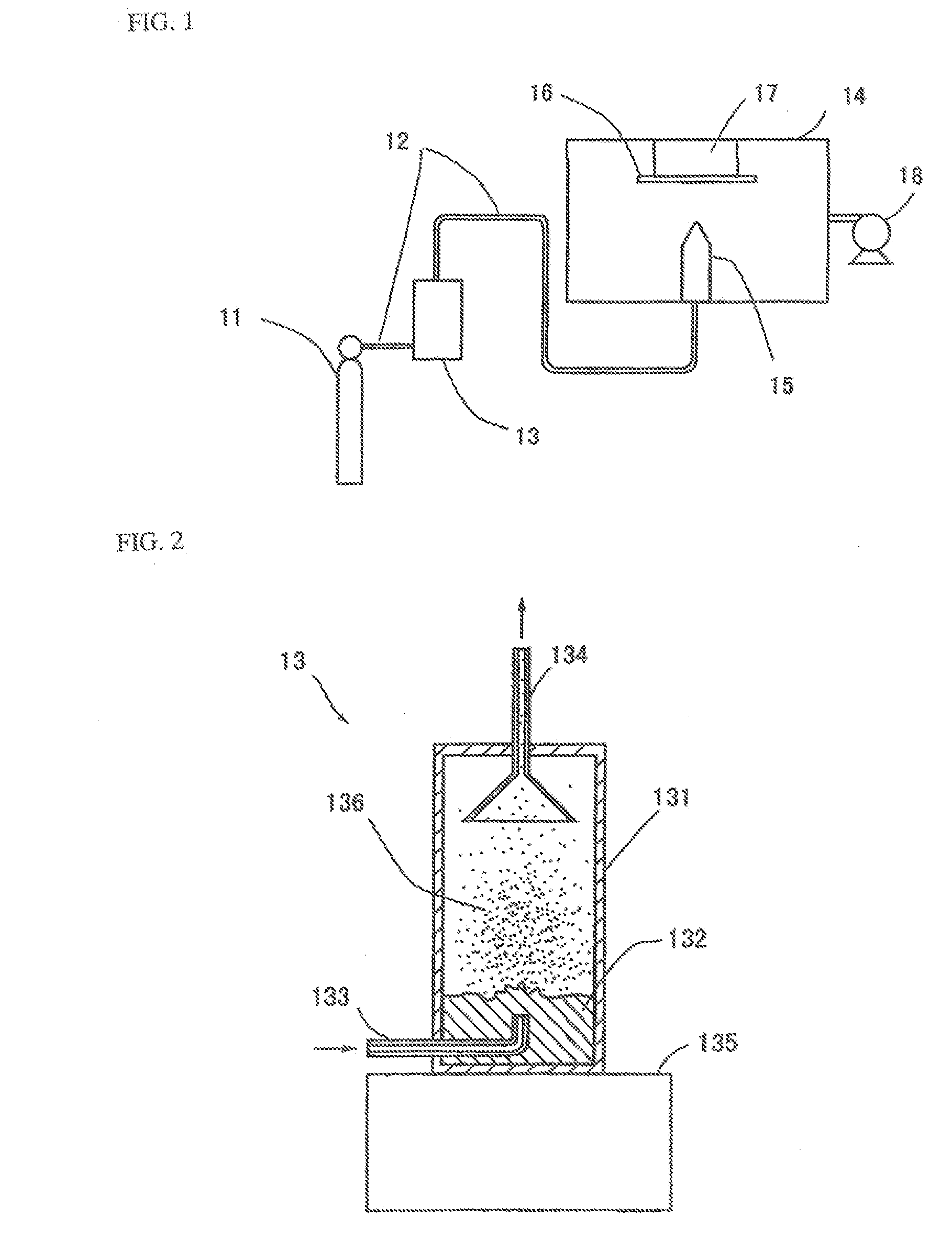

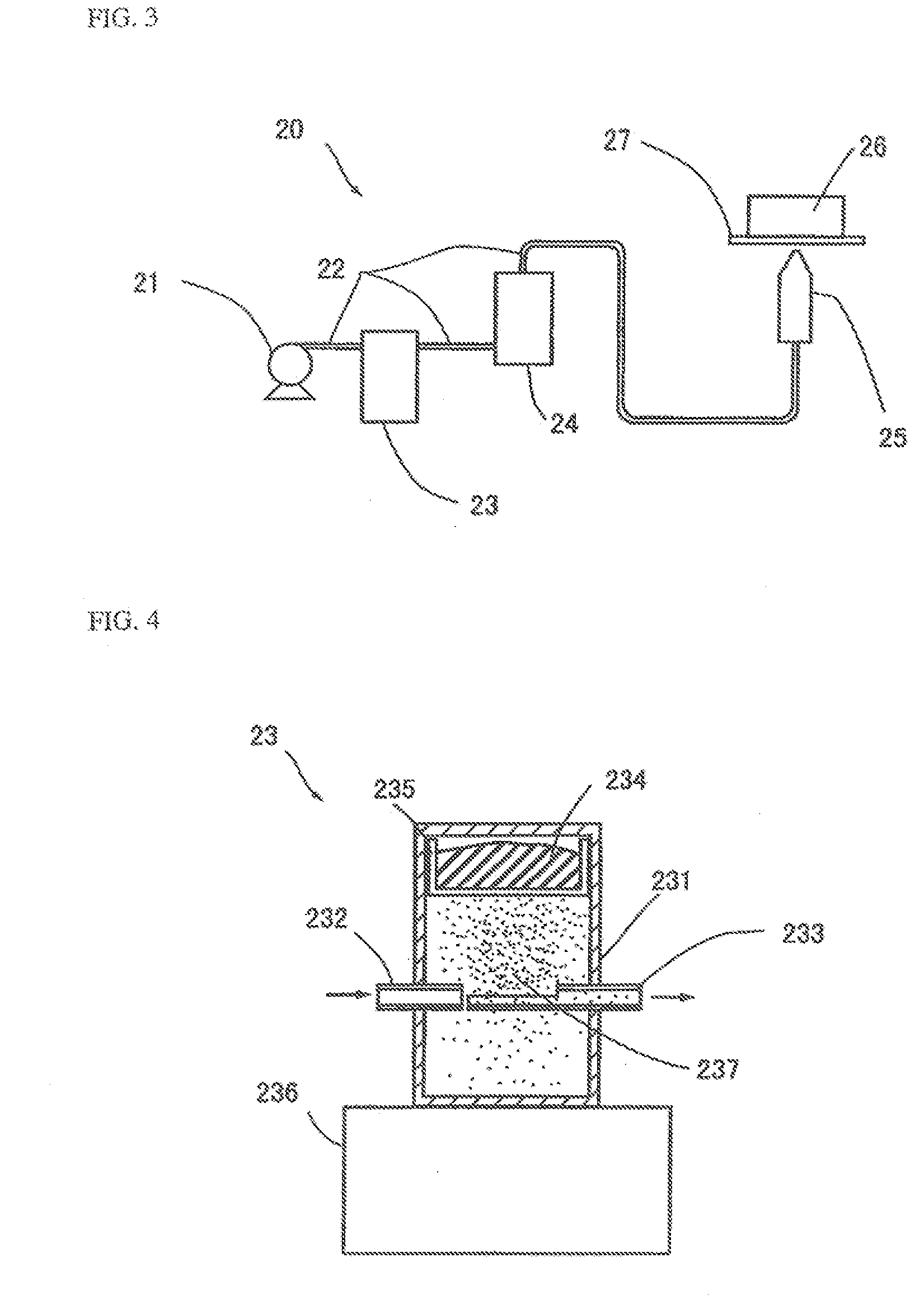

[0113]FIG. 3 is a view showing a second embodiment of a composite structure forming apparatus. In a composite structure forming apparatus 20, an air compressor 21 for providing compressed air is connected to an aerosol generator 23 through a carrier pipe 22. Provided on the downstream side of the aerosol generator 23 is a shredder 24 which is connected to a nozzle 25 with a rectangular opening of 10 mm×0.5 mm. Under atmospheric pressure, a substrate 27 of metal aluminum (Al) is mounted facing the nozzle 25 on a substrate holder 26 which is movable vertically (Z) and longitudinally and laterally (XY) at intervals of 2 mm from the end of the nozzle 25.

[0114]FIG. 4 is a schematic cross-sectional view of the aerosol generator 23 used in the second embodiment. An introduction section 232 connected to the carrier pipe 22 not shown in FIG. 4 is disposed on a level with a guide section 233 connected to the carrier pipe 22, not shown in the figure, relative to a container 231. Provided abov...

third embodiment

[0118]FIG. 6 is a view showing a third embodiment of a composite structure forming apparatus. A nozzle 31 of the composite structure forming apparatus 30 is connected to an aerosol generator not shown in the figure through a carrier pipe 32 made of a flexible material. The nozzle 31 is held by an end of a flexibly movable arm 34 which is controlled by a computer 33 to face a complicatedly shaped object 35 such as a substrate.

[0119] Operation of the above ceramic structure forming apparatus 30 will now be described. The ceramic ultra-fine particles are conveyed from an aerosol generator not shown in the figure through the carrier pipe 32 and ejected onto the surface of the complicatedly shaped object 35 from the nozzle 31 at high speed for deposition. The movable arm 34 is controlled by the computer 33 to trace the surface, i.e., a profile, of the complicatedly shaped object 35 to be coated by the ceramic structure moving at a fixed distance from the surface of the object. In this m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com