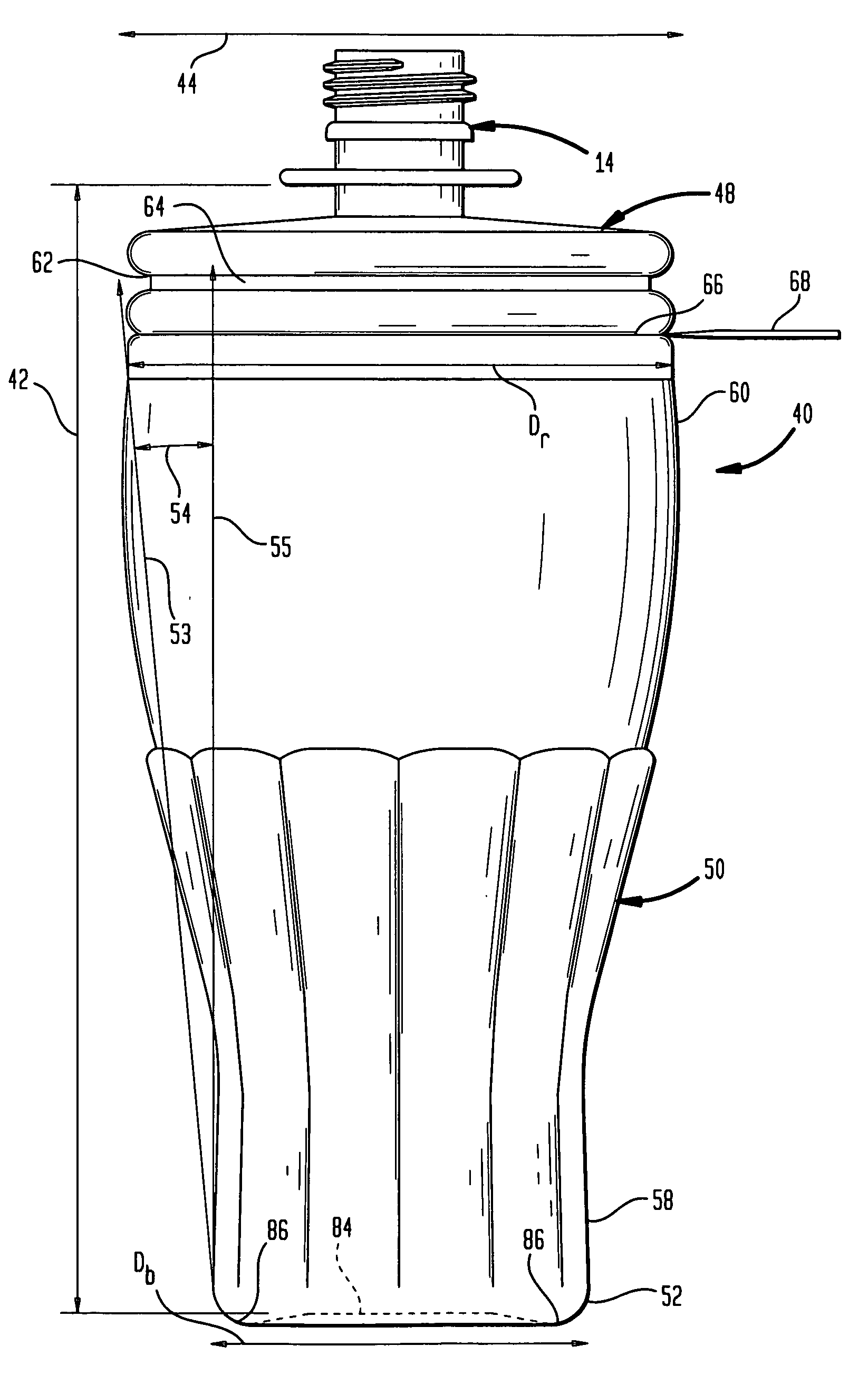

Stretch blow-molded stackable tumbler

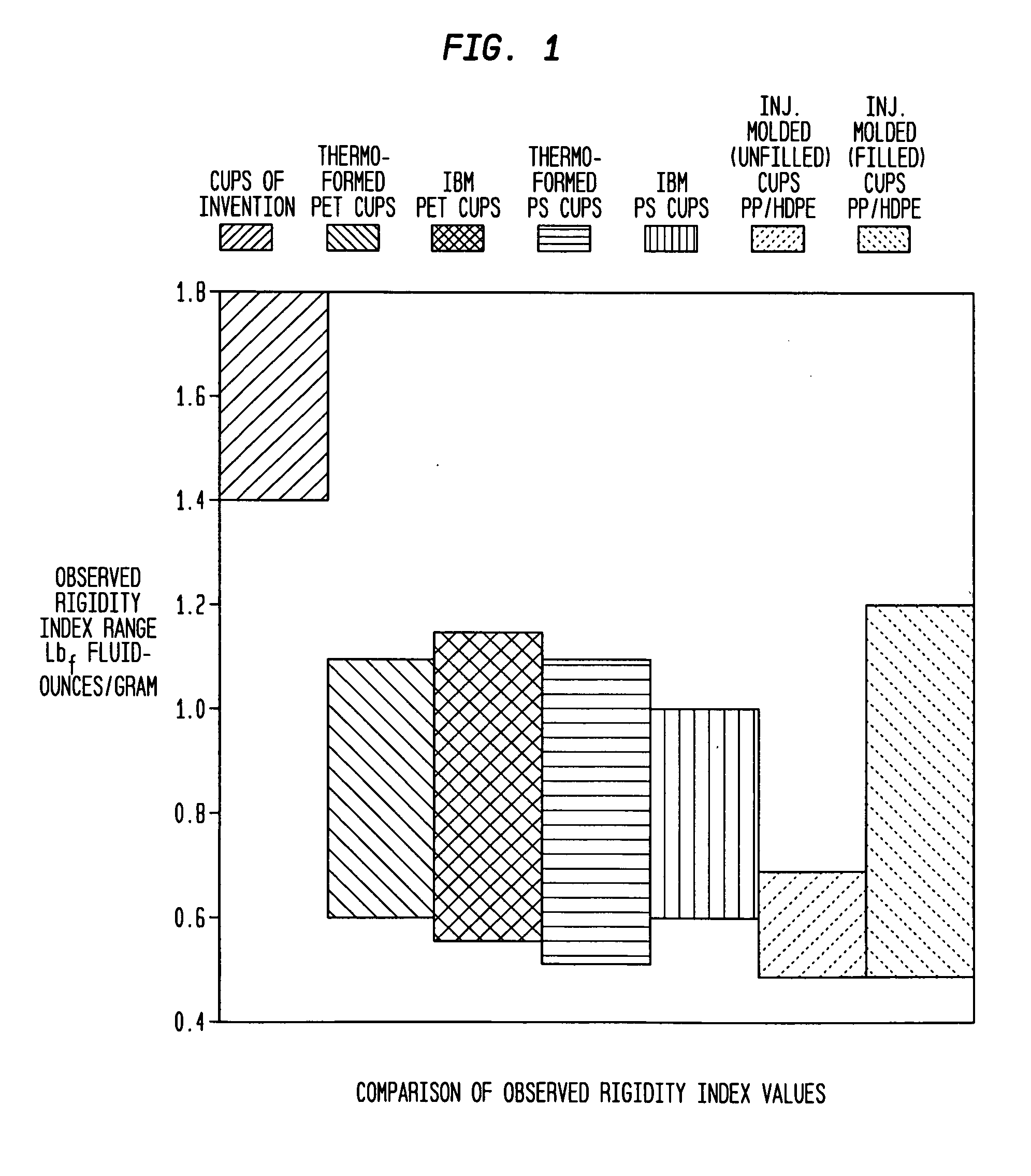

a technology of stackable tumblers and strainers, which is applied in the field of strain blow molding tumblers, can solve the problems of inability to offer unusual cups in unusual configurations or shapes, inconvenient use of materials, and inability to meet the needs of customers, and achieve the effect of providing the needed smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The invention is described in detail below with reference to numerous embodiments, which description is provided for purposes of illustration only. Modifications to those embodiments, within the spirit and scope of the present invention, set forth in the appended claims, will be readily apparent.

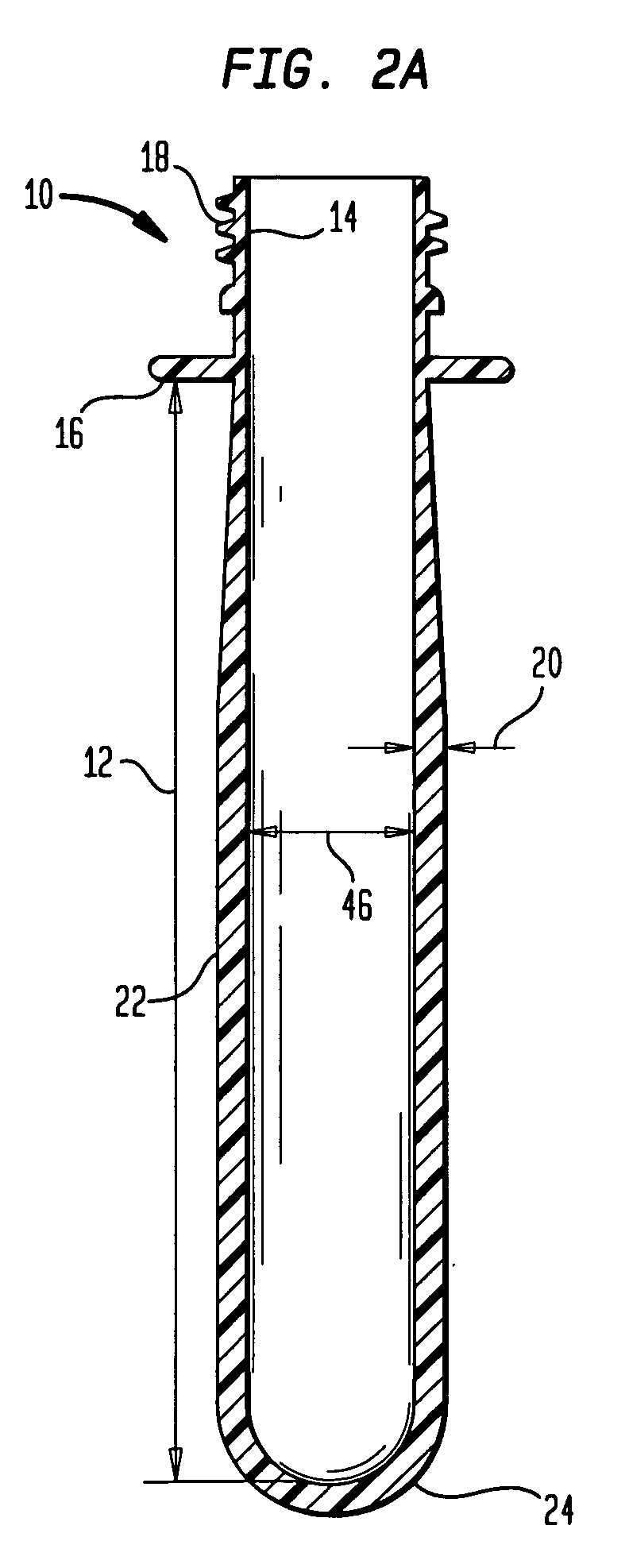

[0045] Unless otherwise defined or the context clearly indicates a more specific meaning, terminology as used herein is given its ordinary meaning. “Tumbler”, for example, refers to a stemless drinking vessel. “Taper” refers to the angle with a vertical defined by a line from the base of a tumbler to its rim. A “polyethylene terephthalate” or “PET” polymer is a polymer having more than 50 mole % polyethylene terephthalate repeat units, whereas a polymer or material “consisting essentially of” polyethylene terephthalate has at least about 90% on a molar basis polyethylene terephthalate repeat units. Such materials are sometimes referred to in the art as “bottle resin” and may include,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com