Ultra-high yield intravenous immune globulin preparation

a high-quality, intravenous technology, applied in the direction of extracellular fluid disorder, drug composition, peptide, etc., can solve the problems of inability to realize industrial scale practicality, increase in temperature, and inability to separate large-weight fractions such as albumin and gamma globulin, so as to reduce production costs, less fractionation steps, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

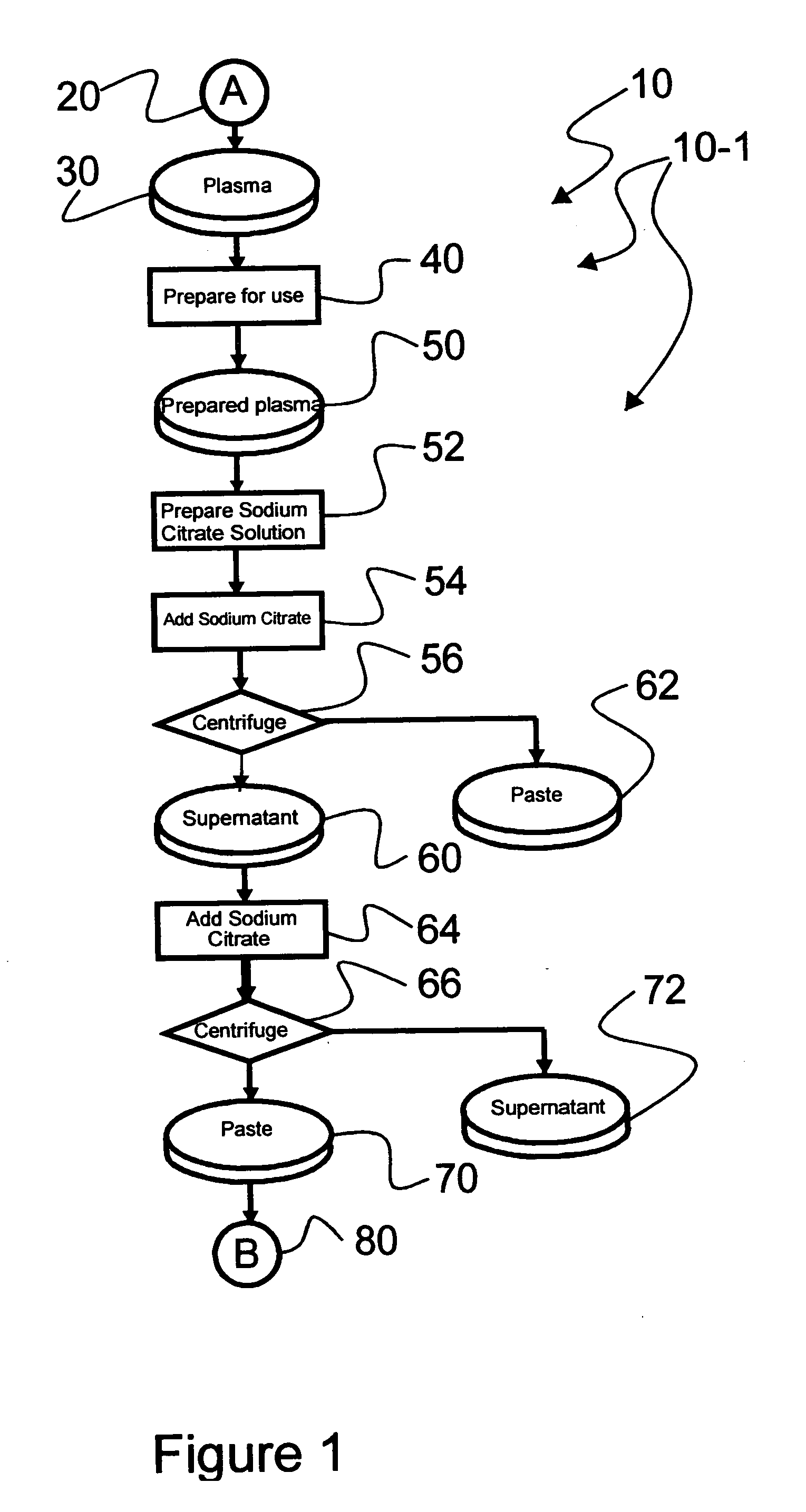

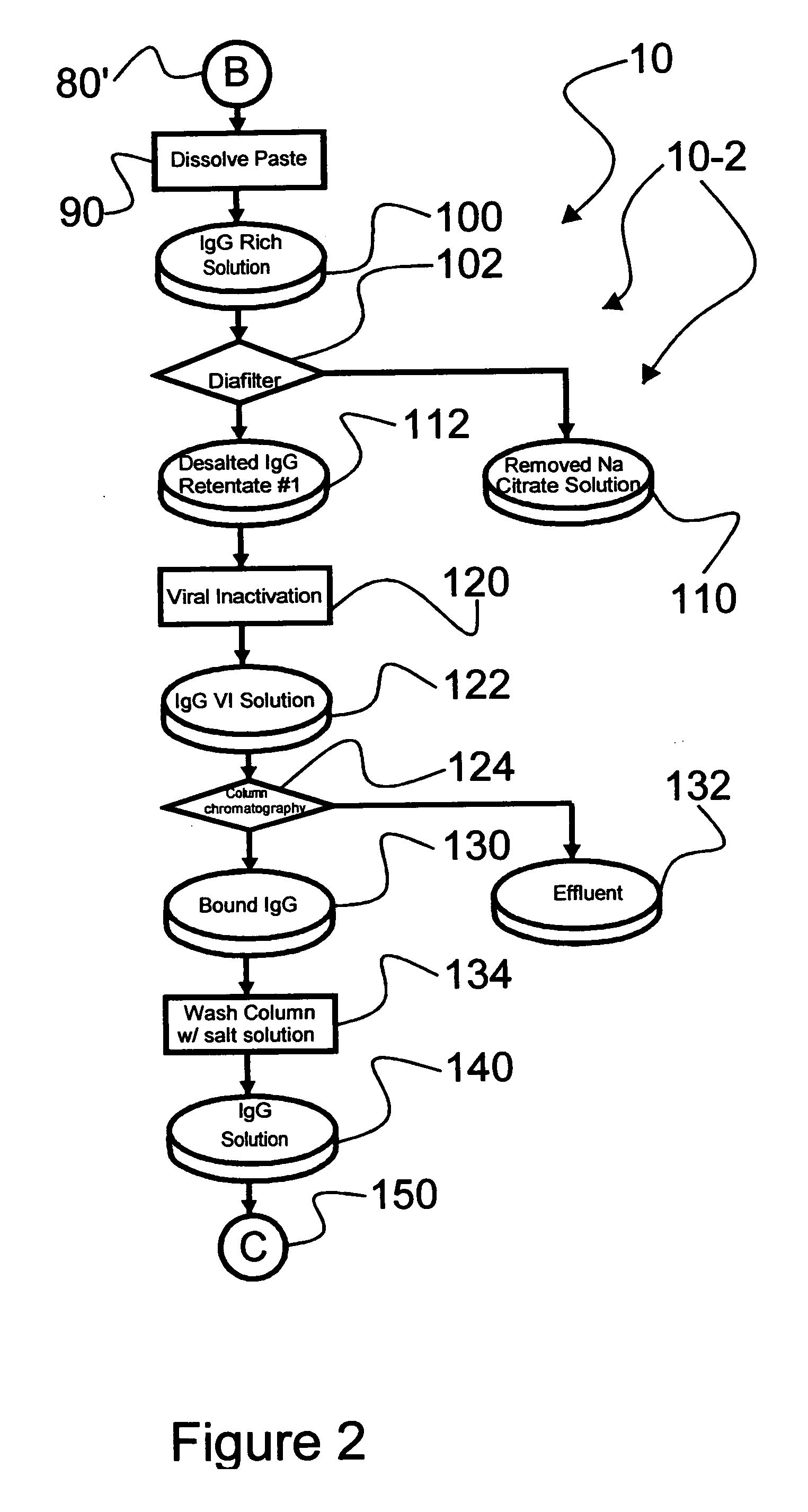

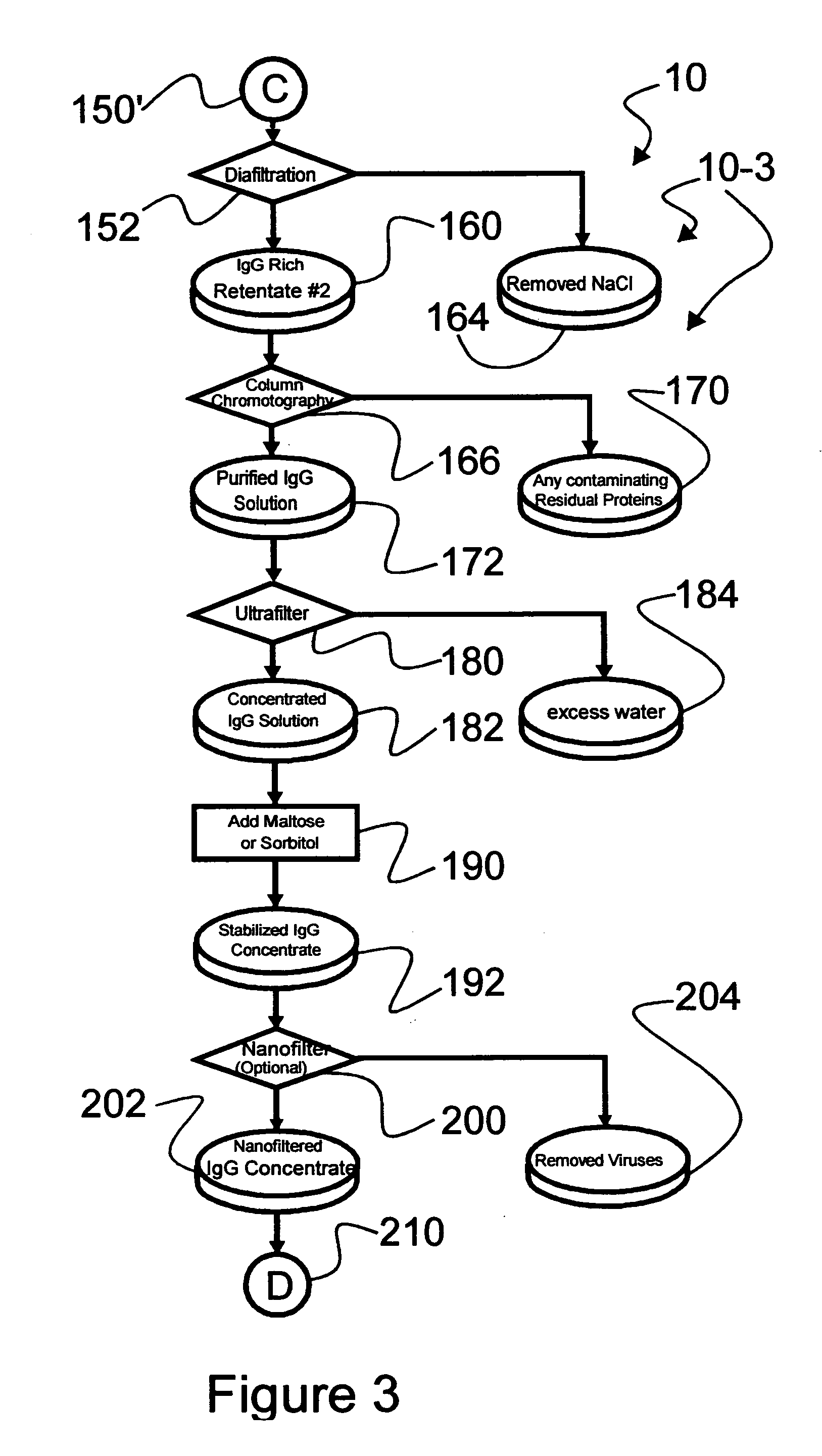

[0036] Reference is now made to flow path elements illustrated in FIGS. 1-4. Generally, each rectangular box is used to illustrate a procedural step; each diamond is used to demonstrate a separation step; each elliptical cylinder designates a product resulting from a preceding procedural or separation step; and each circle is used to identify either a starting point or an off-sheet continuation path point.

[0037] Reference is now made to FIG. 1 wherein an initial portion 10-1 of an preferred IgG process flow path, generally numbered 10, is seen. As indicated after initial starting point 20, a volume of plasma 30 to be processed is selected for processing. It should be noted that while plasma 30 is used by example in this description of an illustrated embodiment, other blood-based products may be processed within the scope of the instant invention.

[0038] As part of procedure 40, selected frozen plasma 30 is warmed to approximately five degrees Centigrade to form prepared plasma 50. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com