Smokeless cooker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

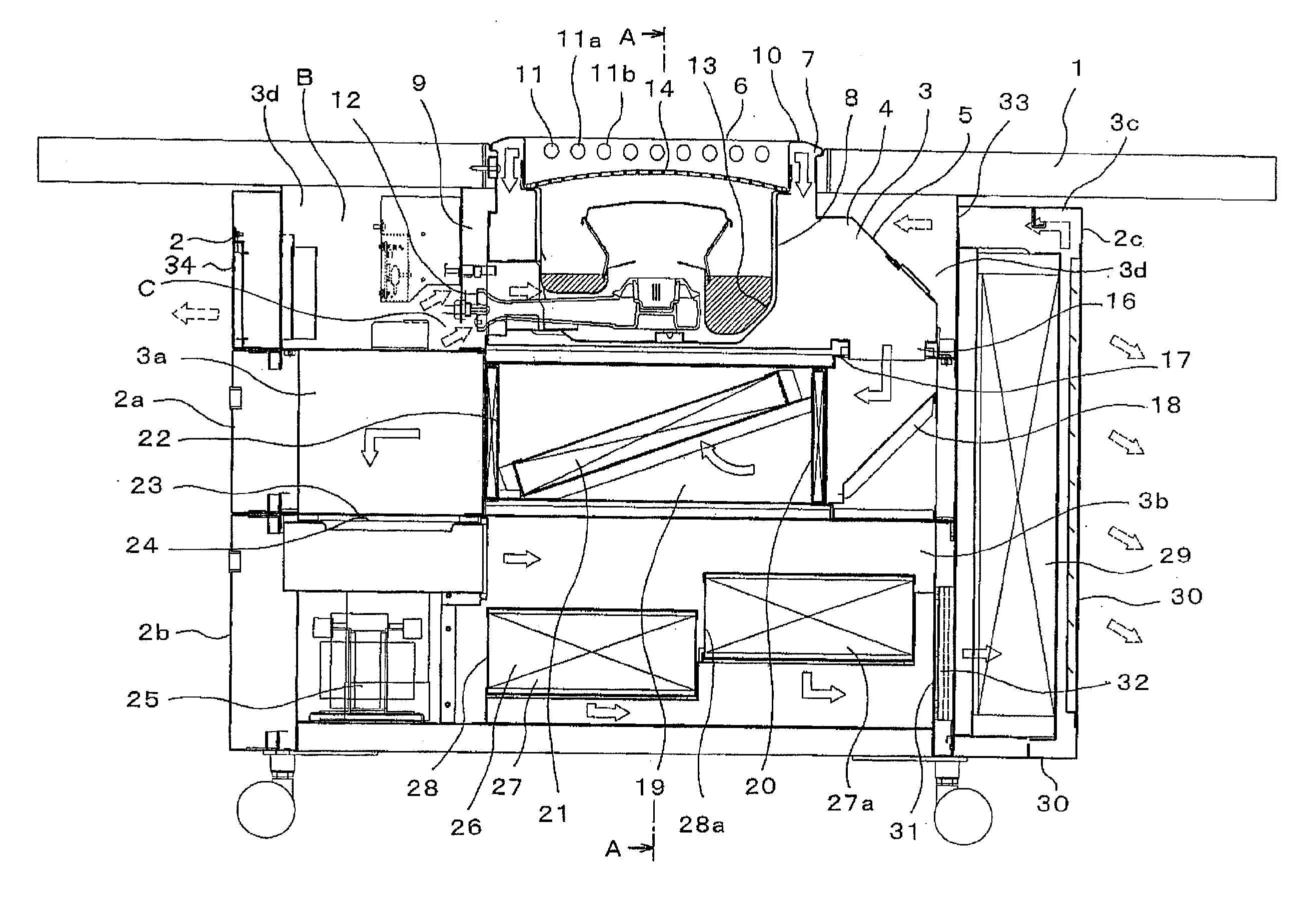

Image

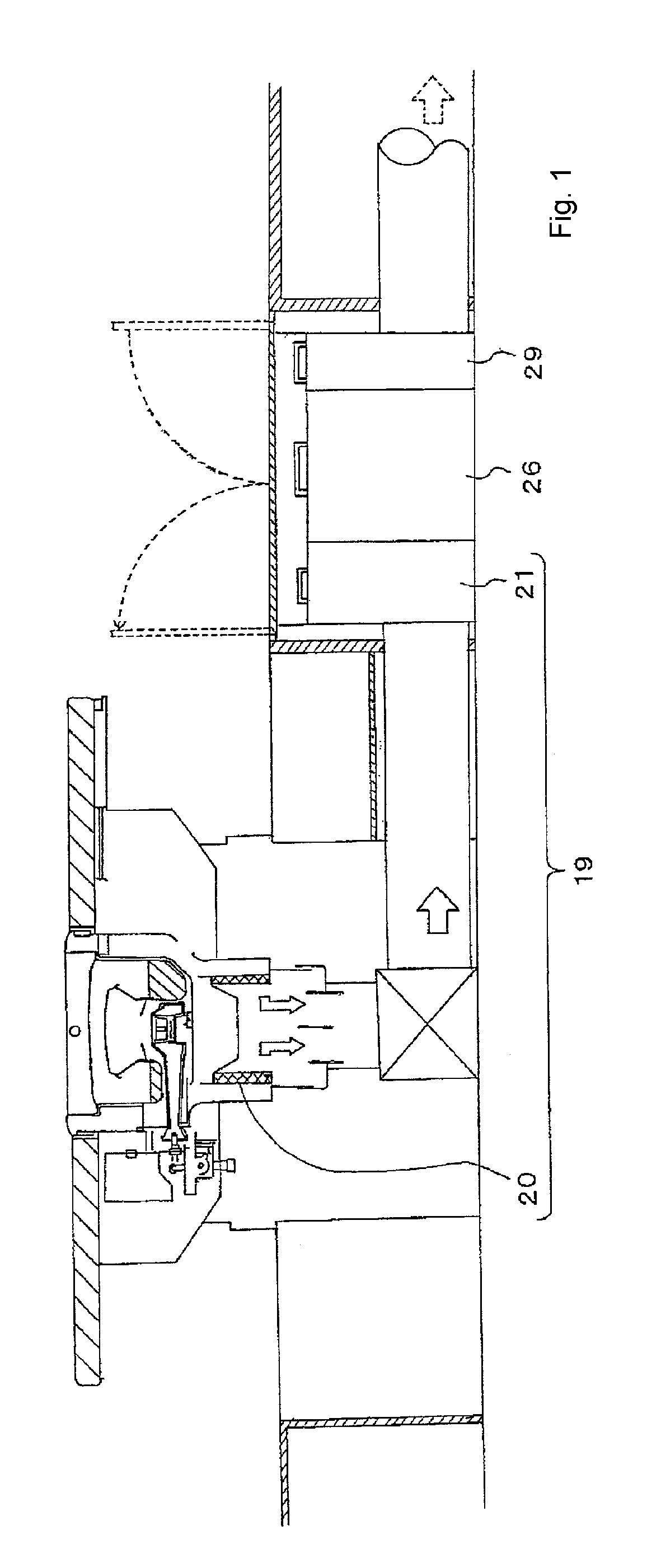

Examples

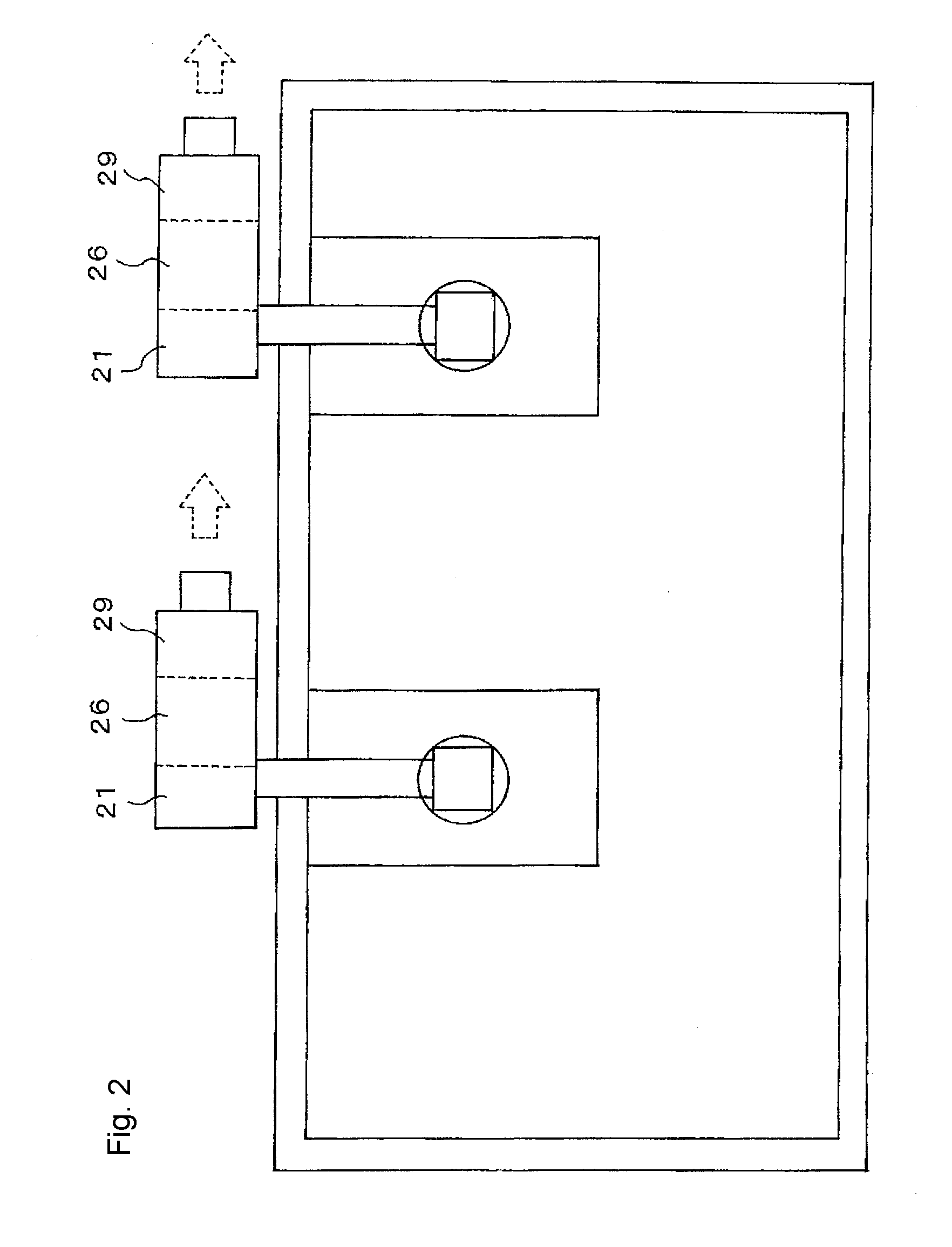

second embodiment

[0068] In the cooker in accordance with this second embodiment, the air supplied for combustion is preferably approximately 50% of total amount of the exhaust gas. Note that the amount of the exhaust gas supplied into the upper box 2 with respect to the total exhaust gas can be controlled by adjusting the opening area of the exhaust opening 30 provided to the side box 2c.

[0069] Further note that, by sending a part of the cleaned exhaust gas into the upper box 2 as described above, the outer face of the outer box 5 disposed in the upper box 2 can be cooled, and thus the temperature of the side wall of the upper box 2 can be prevented from rising unduly.

[0070] To facilitate recycling of materials, each of the boxes 2, 2a, . . . , may be made of metal. The box body with an open front face and the cover attached to the outside of the box body may be made of a plastic. To facilitate recycling when disassembling the boxes, a plastic cover may be detachably attached to the box body.

[007...

embodiment 3

[0082] The separable smokeless cooker in accordance with the embodiment 3 is characterized in that the IH heater is employed as the heat source. The IH heater generates heat by induction heating of an iron plate. In a gas heater or the like, radiant heat and heat convection utilizing far infrared radiation are used. An IH heater uses a heat input amount and a heating temperature with respect to the cooked object that are low in comparison with gas heating or the like. It is thus known that roasting a meat using an IH heater generates less oil smoke in comparison with a gas flame. This is because no flame is present to burn meat juices generated from the heated meat.

[0083] In other words, the separable smokeless cooker in accordance with this embodiment can reduce the generation of oily smoke. The load on the filters and the active charcoal in the deodorizing unit are thereby reduced. Accordingly, the replacement cycle of the consumable parts can be extended, which yields a reduced o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap