Heating recycling system for regenerating the absorptive materials

a technology of absorption carbon and recycling system, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, chemistry apparatus and processes, etc., can solve the problems of high temperature decomposition, destruction of the cellulose structure of the adsorbent carbon, and energy consumption in the regeneration process of these absorption materials, so as to improve the air quality in the vehicle, improve the efficiency of the heating process, and reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

The Heat Recycling System is Employed in an Air Freshening System In-vehicle

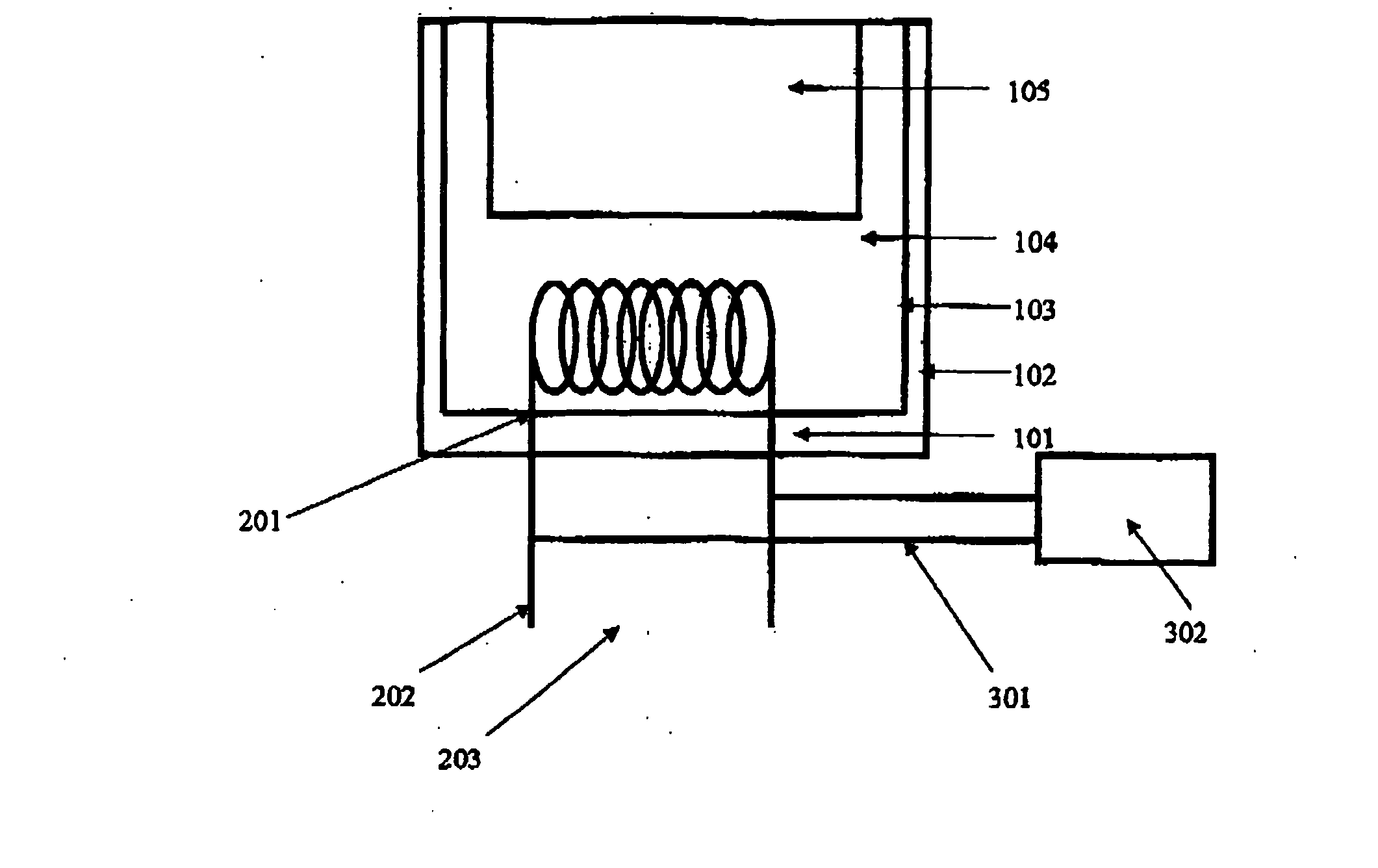

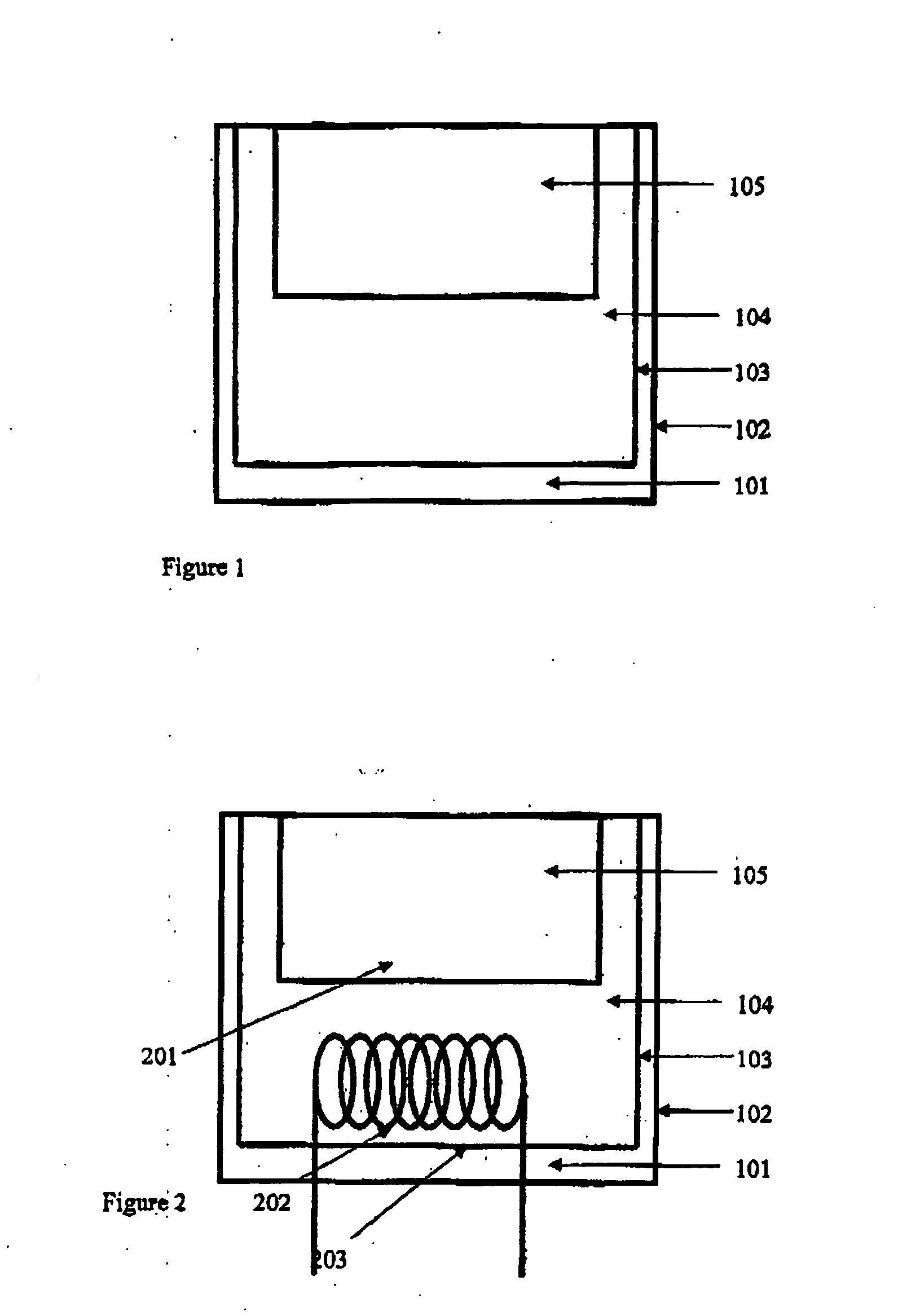

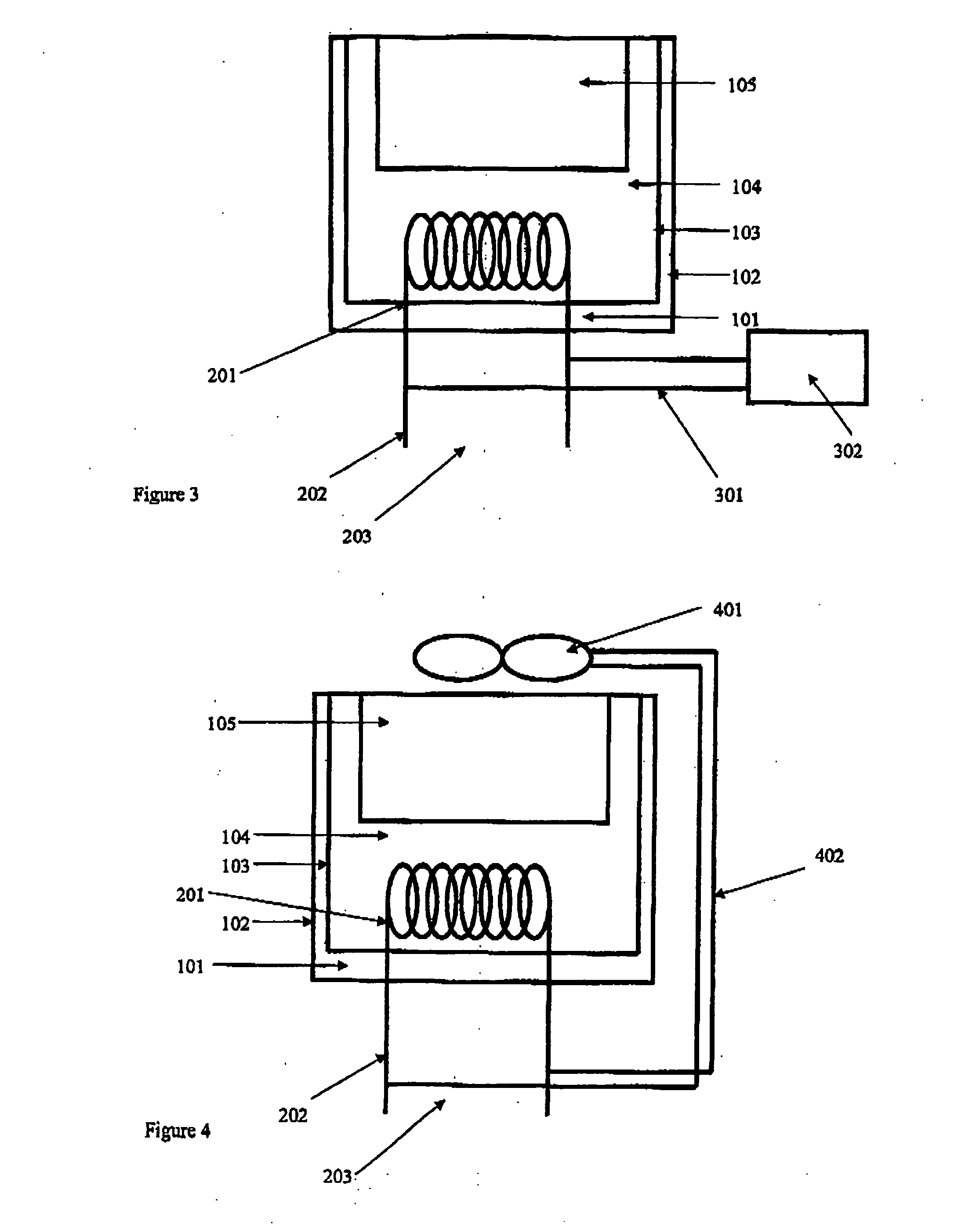

[0059] The designs of FIG. 1 to 7 are employed in this example. The absorptive materials contains 100 g zeolite 4A which was pretreated by soaking into 30 g of aroma solution (10-40% lavender oil and 60-90% isopropanol) followed by air drying. The thermal storage materials contain of 50-65 g Magnesium Nitrate and 35-50 g water. The mixture was allowed to heat until all magnesium nitrates was dissolved.

[0060] The phase change temperature for the thermal storage materials is 55° C.-62° C. During it phase change; the aroma oil will be released slowly and stably to the environment.

example 2

The Heat Recycling System is Employed in an Air Freshening System In-vehicle

[0061] The designs of FIG. 1 to 7 are employed in this example. The absorptive materials contains 100 g zeolite 4A which was pretreated by soaking into 30 g of aroma solution (10-40% rose oil and 60-90% isopropanol) followed by air drying. The thermal storage materials contain of 17-25% calcium chloride and 17 to 25% water. The mixture was allowed to heat until all calcium chloride was dissolved.

[0062] The phase change temperature for the thermal storage materials is 27° C.-31° C. During it phase change; the aroma oil will be released slowly and stably to the environment.

[0063]FIG. 10 indicates the temperature conditions when the heat recycling system was employed in a vehicle which was packing out door. Since the vehicle was irradiated by the outdoor sunshine, the longer wavelength infra-red light was not able to escape after entered into the vehicle. The temperature inside the vehicle therefore increase...

example 3

Mosquitoes Repelling Device

[0064] The designs of FIG. 1 to 7 are employed in this example. The absorptive materials contains 100 g zeolite 13A which was pretreated by soaking into 5 g of mosquitoes repelling solution (20-40% citronella oil, 5-10% diethyl-m-toluamide and 50-70% isopropanol) followed by air drying. The thermal storage materials contain of 50-65 g Magnesium Nitrate and 35-50 g water. The mixture was allowed to heat until all magnesium nitrates was dissolved.

[0065] The phase change temperature for the thermal storage materials is 55° C.-62° C. During it phase change; the mosquito's repelling solution will be released slowly and stably to the environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com