Method for the removal of deposits on the internal walls of industrial furnaces of bunkers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

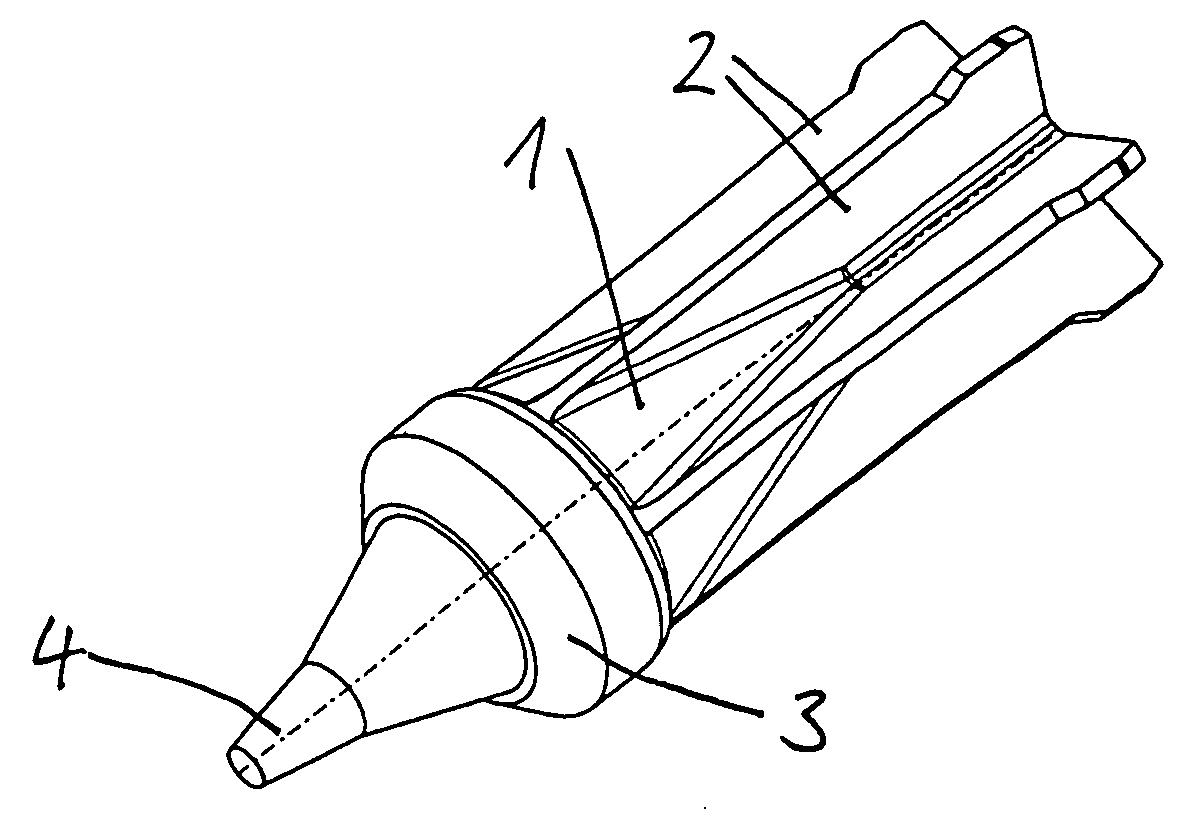

[0029]FIG. 1 shows in a perspective view a shell 1 with an impact detonator for use in connection with the method according to the invention. The shell has for example a diameter of 40 mm and a length of about 130 mm. It comprises a shell body 1 forming a shell sleeve with flight stabilization fins 2, a cover 3 forming the front part and an impact detonator 4 disposed at the front end of the cover 3. The hollow space surrounded by shell body 1 and the cover 3 is filled with a charge of an explosive material or a pyrotechnical material.

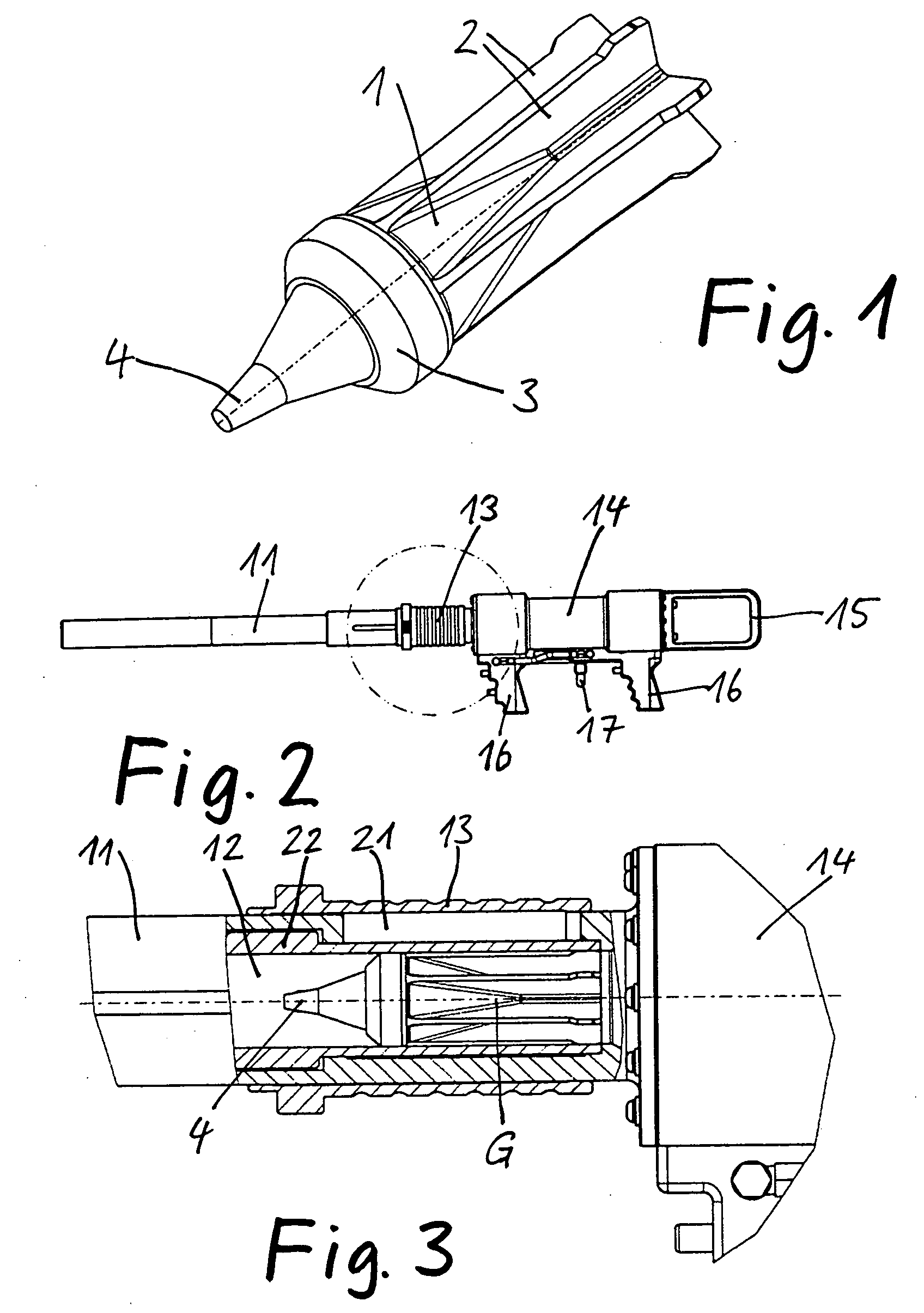

[0030]FIG. 2 shows, in a side view, an industrial cannon for shooting shells as shown in FIG. 1. It includes a barrel 11, a shell chamber 12 at the rear end of the barrel 11, which can be closed by an axially movable closure sleeve 13, and a cannon body 14 with a rear carrying handle 13 and operating handles 16 as well as a compressed air connector 17.

[0031]FIG. 3 shows the area of interest of the industrial cannon which is operated by compressed air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com