Thin film organic position sensitive detectors

a position sensitive, organic technology, applied in thermoelectric devices, instruments, radio frequency controlled devices, etc., can solve the problems of inability to continuously detect signals, difficult and expensive production, and difficult to produce high-efficiency crystalline devices, etc., to achieve enhanced response time, high detection resolution, and increased potential barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

ication

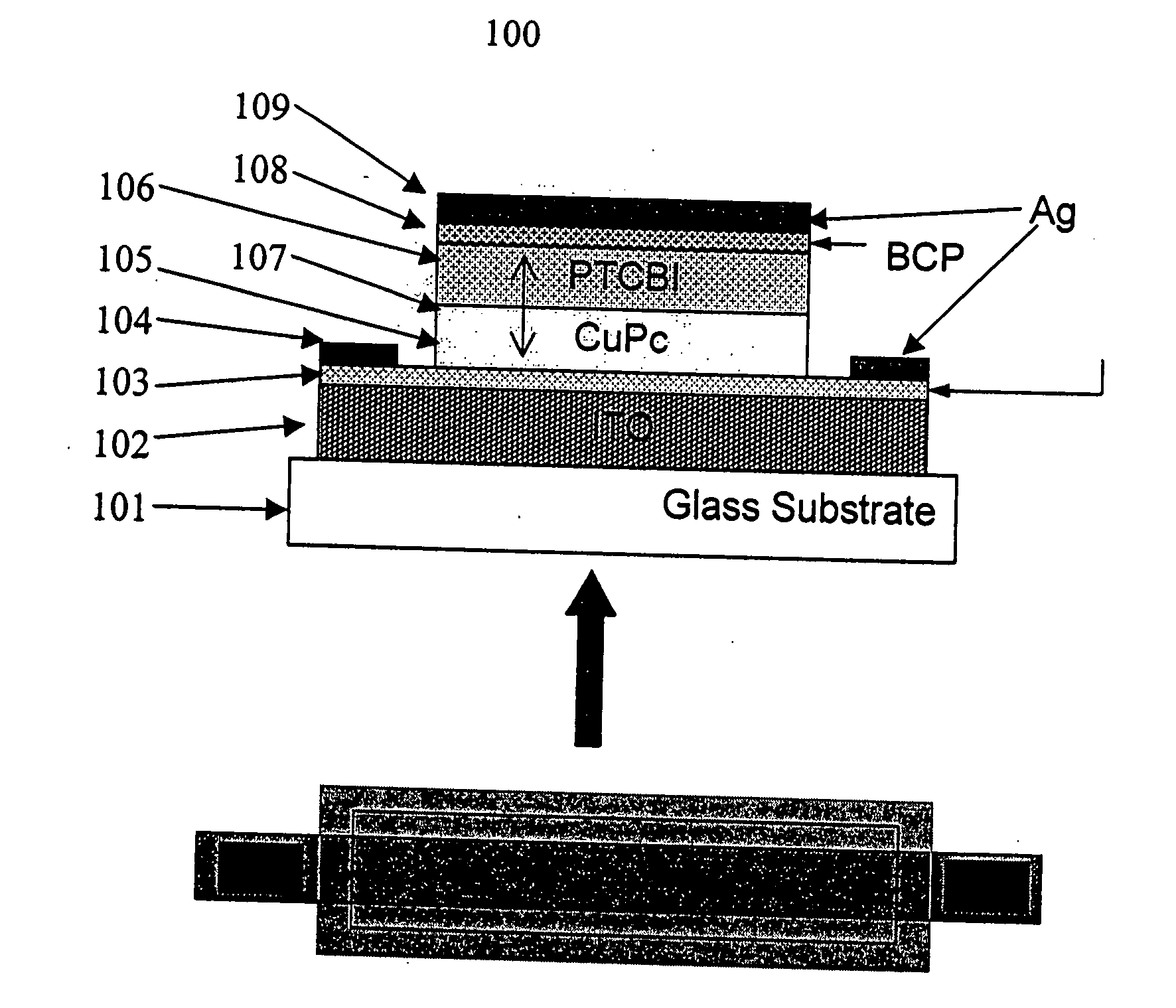

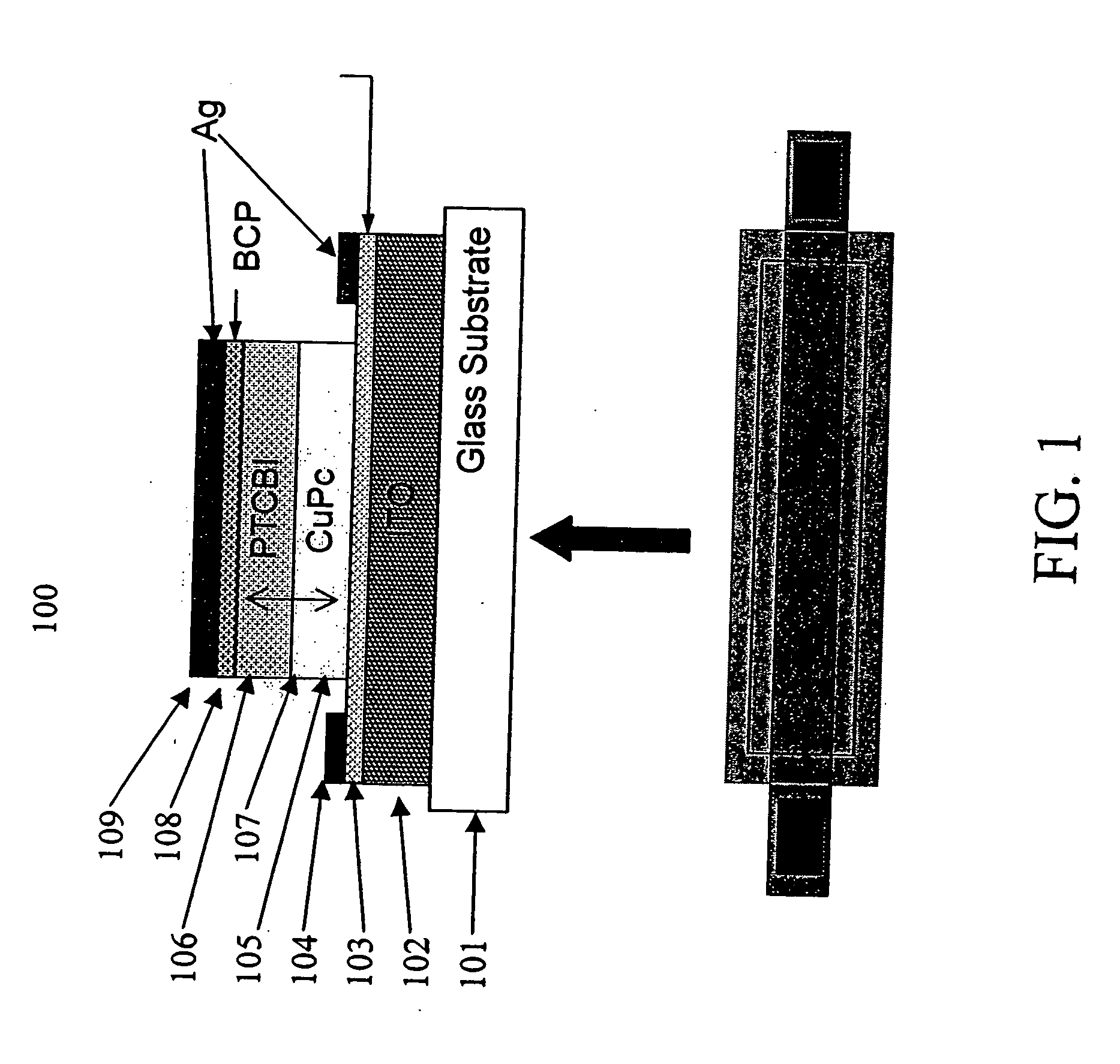

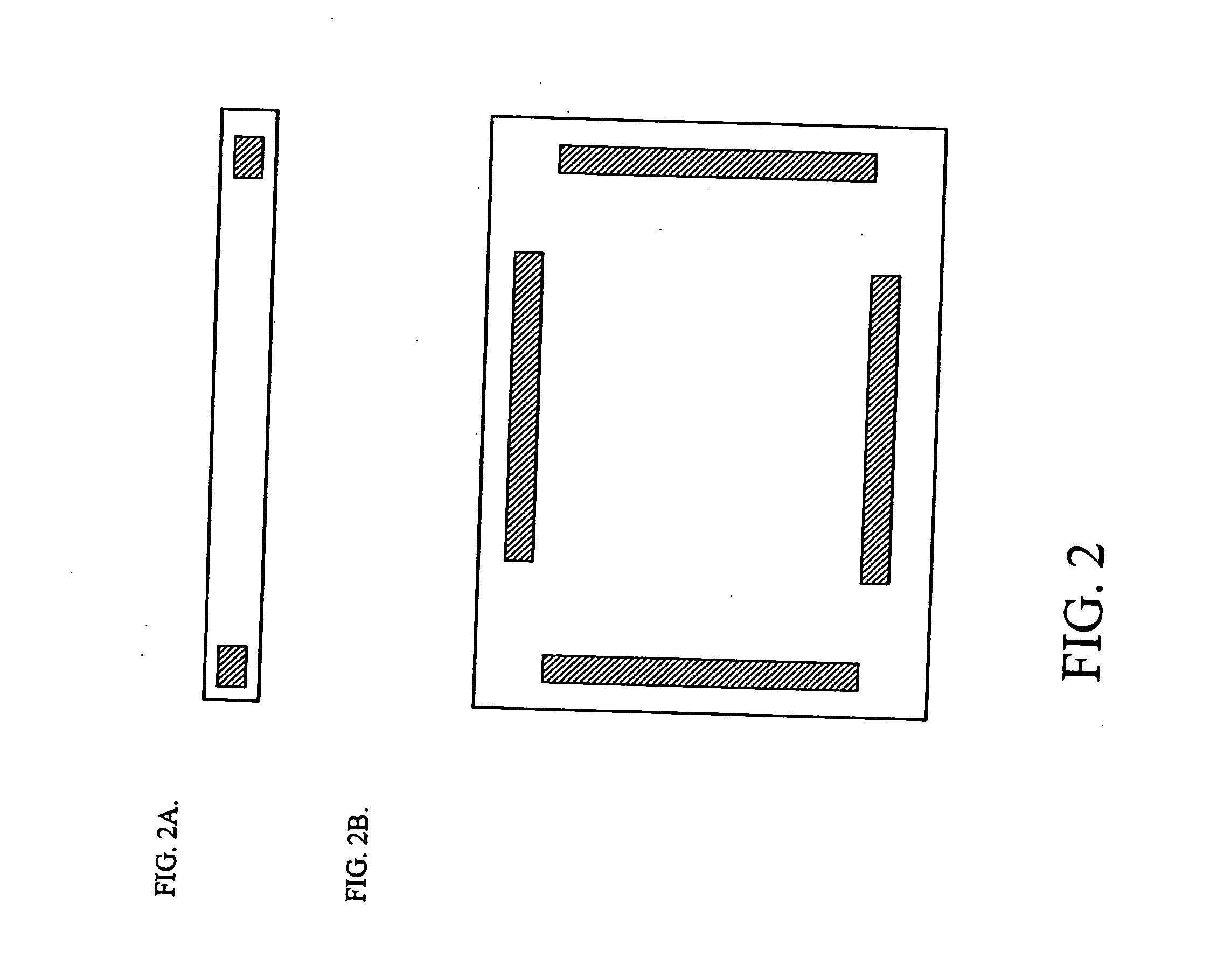

[0074] An OPSD was fabricated on precleaned glass substrates commercially precoated with a 1500 Å-thick ITO anode obtained from Applied Films Corporation in Longmont Colo. (P. E. Burrows, Z. Shen, V. Bulovic, D. M. McCarty, S. R. Forrest, J. A. Cronin, and M. E. Thompson, “Relationship between electroluminescence and current transport in organic hetero-junction light-emitting devices,” J. Appl. Phys., vol. 79, no. 10, pp. 7991-8006, May 1996.) A single photolithographic step was used to pattern and etch the ITO (in 5% HNO3: 45% HCl: 50% H2O by volume at 70° C. for 5 min) into a 3 cm×1 mm line. The ITO was then spin-coated with a 300 Å-thick film of 3,4-polyethylenedioxythiophene:polystyrenesulfonate (PEDOT:PSS), followed by drying at 120° C. for 15 min in vacuum. The PEDOT:PSS layer improves current injection into the donor-like copper phthalocyanine (CuPc) layer by lowering the Fermi-level, and hence reducing the energy barrier to holes by 0.5 eV with the highest occupied mo...

example 2

ng the Electronic and Optical Characteristics of the OPSD

[0075]FIG. 4 shows the current density-versus-voltage characteristics for the OPSD in the dark and under different intensities at a wavelength of λ=632.8 nm using a HeNe laser. The signal-to-background ratio (SBR) can be defined as Iph / ID, where Iph is the photocurrent and ID is the dark current of the device. A minimum SBR of 9 satisfies the condition IDph such that the OPSD response is linear and thus leads to an accurate determination of Δx. In particularly preferred embodiments, SBRs>1000 are achieved at low reverse bias for optical powers>500 μW.

[0076] The absorption (solid line) and external quantum efficiencies (ηEXT) for different applied voltages (dashed lines) are shown in FIG. 5. The absorption has three peaks at λ=550, 610, and 680 rim. The λ=550 nm peak is due to the PTCBI layer while CuPc is responsible for the shoulder at λ=610 nm and the peak at λ=680 nm. Note that ηEXT differs from the absorption spectrum sin...

example 3

of the OPSD

[0077] All 3 cm×1 mm OPSDs were scanned using a translation stage accurate to less than 10 μm and an optical beam of diameter 180 μm. To characterize beam tracking accuracy, the nonlinearity factor, δ=2σ / F was used, where σ is the root mean square deviation from a regression line fit to the measured position, and F is the full positional range of the data. Typically, δ<0.15 is sufficient for many applications. (E. Fortunato, G. Lavareda, R. Martins, F. Soares, and L. Fernandes, “Large-area 1 D thin-film position-sensitive detector with high detection resolution,” Sensor Actuat. A: Phys., vol. 51, no. 2-3, pp. 135-142, February 1996.) Another important parameter for the OPSD is the measurement error, Σ=(ΔI / L) where Δ1 is the difference between the actual and calculated optical beam positions. (S. Arimoto, H. Yamamoto, H. Ohno, and H. Hasegawa, “Hydrogenated amorphous silicon position sensitive detector,” J. Appl. Phys., vol. 57, no. 10, pp. 4778-4782, May 1985.) In FIG. 7,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com