Diagnosis system for vane-type variable valve timing controller

a technology of variable valve timing controller and diagnostic system, which is applied in the direction of valve arrangement, machines/engines, mechanical equipment, etc., can solve the problems of abnormal advance/retard operation, valve not operating normally, and deteriorating mounting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

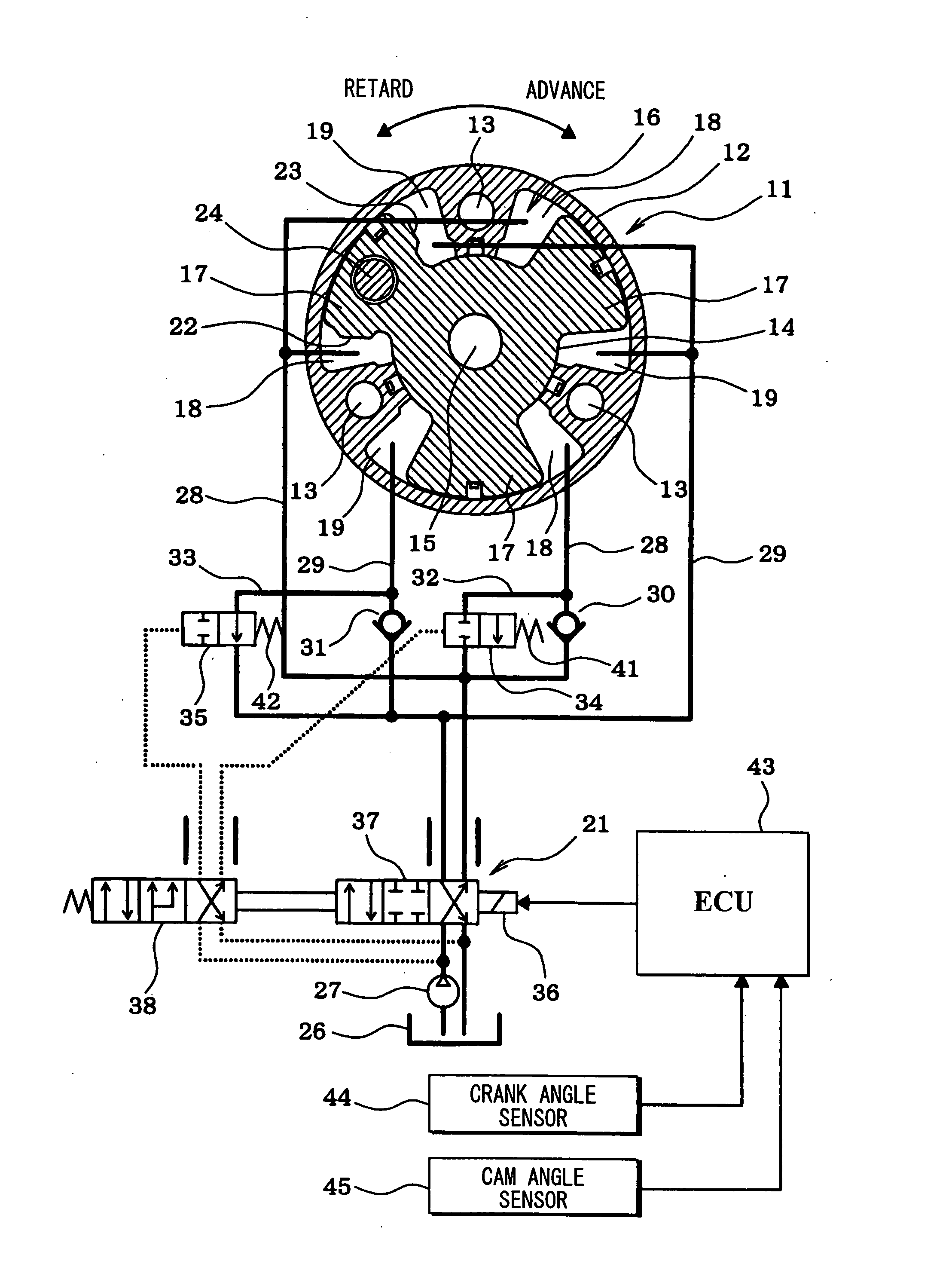

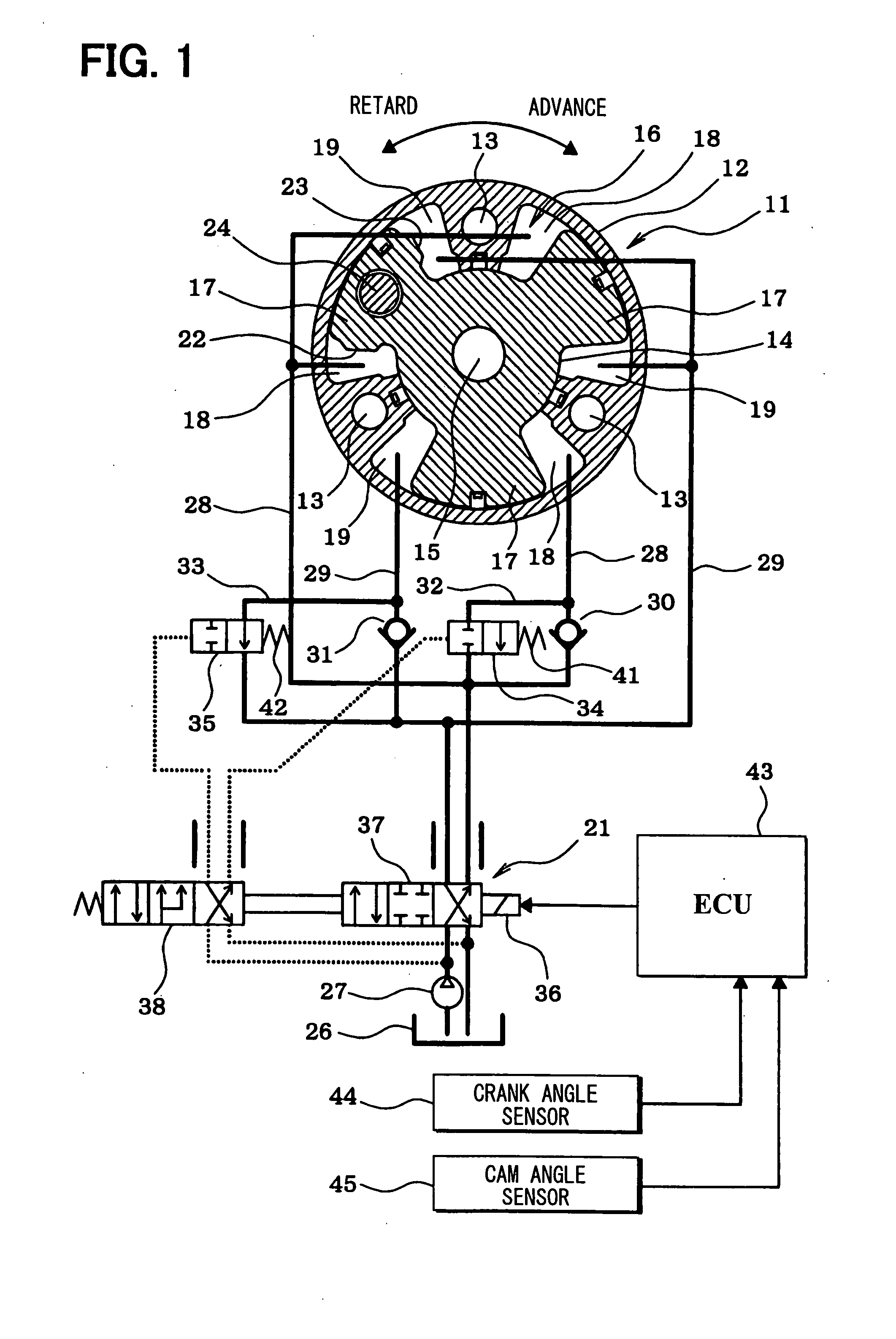

[0045] First, a structure of a vane-type variable valve timing controller 11 will be explained with reference to FIG. 1. A housing 12 of the variable valve timing controller 11 is clamped and fixed to a sprocket rotatably supported at an outer periphery of a cam shaft in an intake side or an exhaust side (not shown) by bolts 13. In consequence, rotation of a crankshaft for an engine is transmitted through a timing chain to the sprocket and the housing 12 and the sprocket and the housing 12 rotate in a timed relation to the crankshaft. A vane rotor 14 is accommodated inside the housing 12 so as to rotate relative thereto and is clamped and fixed to one end of the camshaft by a bolt 15.

[0046] A plurality of vane accommodating chambers 16 for accommodating a plurality of vanes 17 at an outer periphery of the vane rotor 14 so as to rotate in the advance direction or the retard direction relative to the housing 12 are defined inside the housing 12 and each vane accommodating chamber 16 ...

embodiment 2

[0113] Embodiment 2 detects abnormality by using the following method, considering that in a region of a high-rotation side where an engine rotational speed is more than a predetermined value, the drain switching valves 34 and 35 respectively are forcibly opened due to the rotational centrifugal force all the time regardless of the control hydraulic pressure in the drain switching valves 34 and 35 respectively, creating the state where the functions of the respective one-way valves 30 and 31 do not work.

[Abnormality Diagnosis in a Region at a Low Rotation Side]

[0114] During holding operating, in a region of a low rotation side less than a predetermined rotational speed where the drain switching valves 34 and 35 of both the sides are closed if they are normal, as shown in FIG. 8, the holding current (hold duty) of the hydraulic control valve 21 is vibrated (dither) in a predetermined amplitude / cycle to determine a changing degree of the VTC displacement angle by the vibration of th...

embodiment 3

[0178] In Embodiment 3, the open abnormality will be detected as follows.

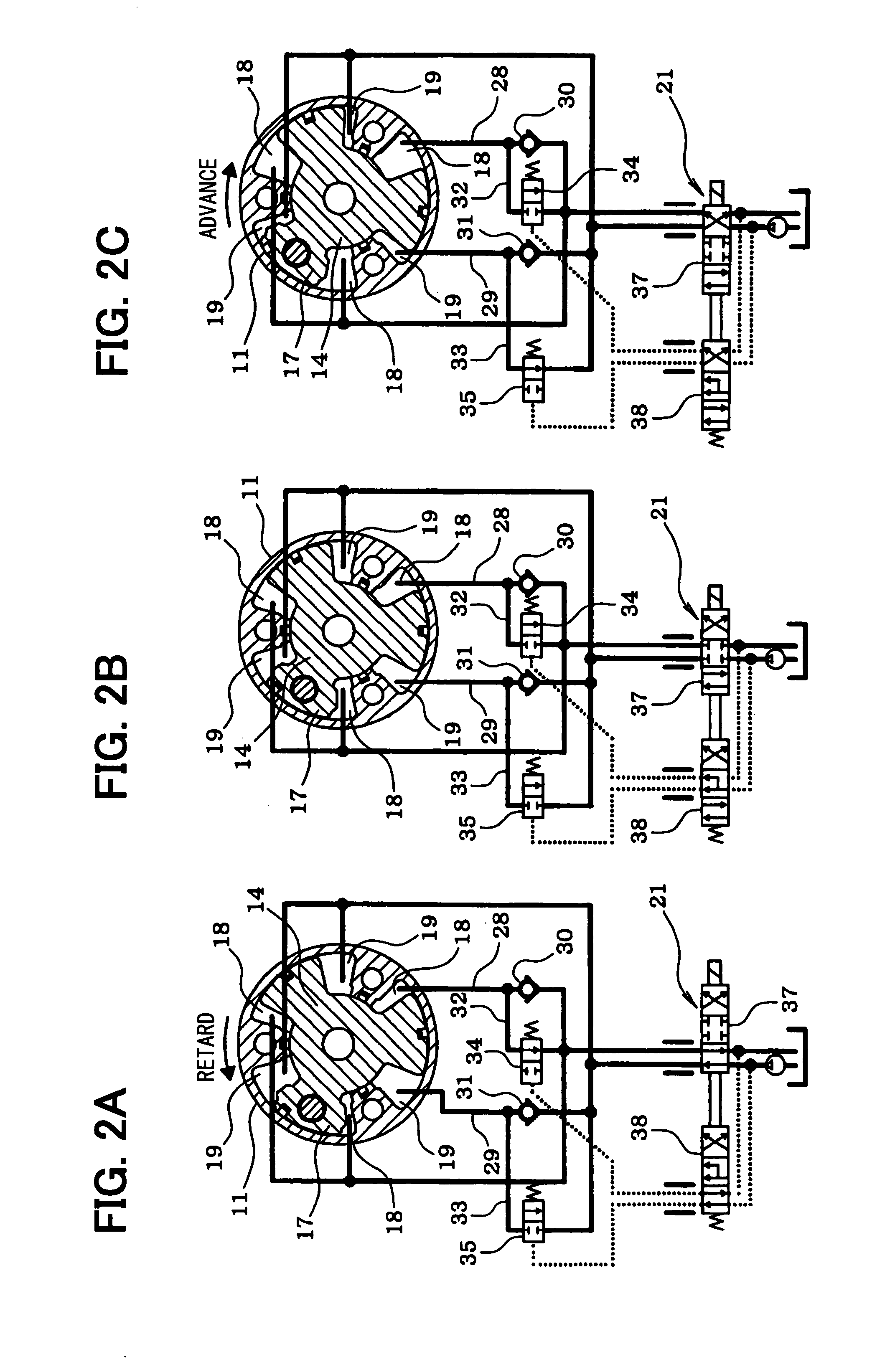

[0179] When both of the drain switching valves 34 and 35 in the side of the advance hydraulic chamber 18 and in the side of the retard hydraulic chamber 19 operate normally during holding operating, both of the drain switching valves 34 and 35 close. Therefore, when both of the one-way valves 30 and 31 are normal, a reverse flow prevention function of each of the one-way valves 30 and 31 can be made to effectively operate. However, when there occurs the open abnormality state where either one of the drain switching valves 34 and 35 (or the one-way valves 30 and 31) remains to be opened, either one of the drain switching valves 34 and 35 (or the one-way valves 30 and 31) is fixed in a state of being opened even during the holding operating. Accordingly, when either one of the drain switching valves 34 and 35 (or the one-way valves 30 and 31) is in an open abnormality state, the hydraulic pressures in the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com