Polyester Conjugated Yarn Having High Self-Crimping Properties and Method of Manufacturing the Same

a polymer and self-crimping technology, applied in the field of polymer conjugated yarns, can solve the problems of low spinnability, difficulty in mounting manufacturing equipment in a large scale, and inferior crimp properties of single spinning methods using quenching, and achieve superior spinnability and elasticity, good dyeability, and maximum difference of intrinsic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-6

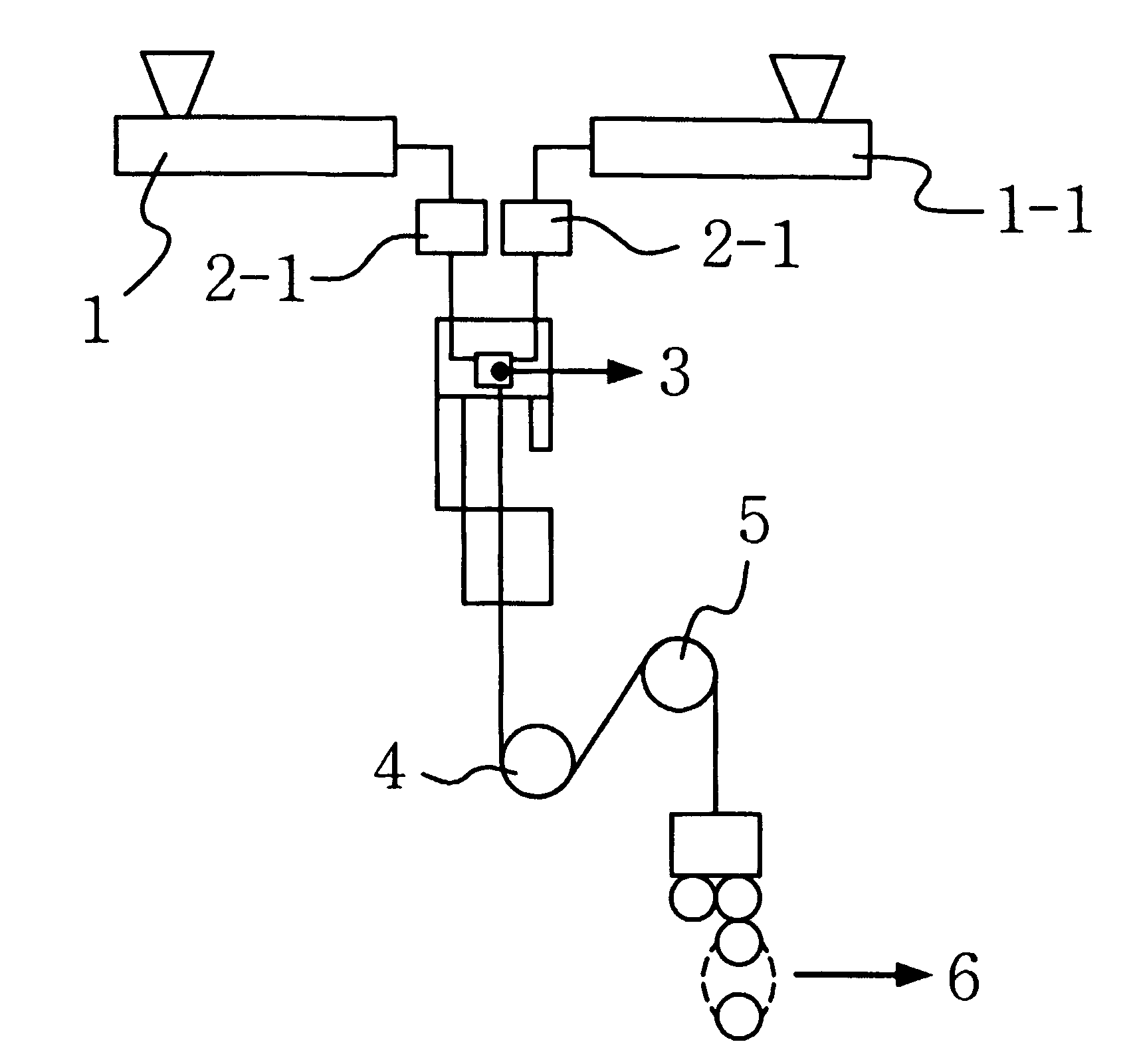

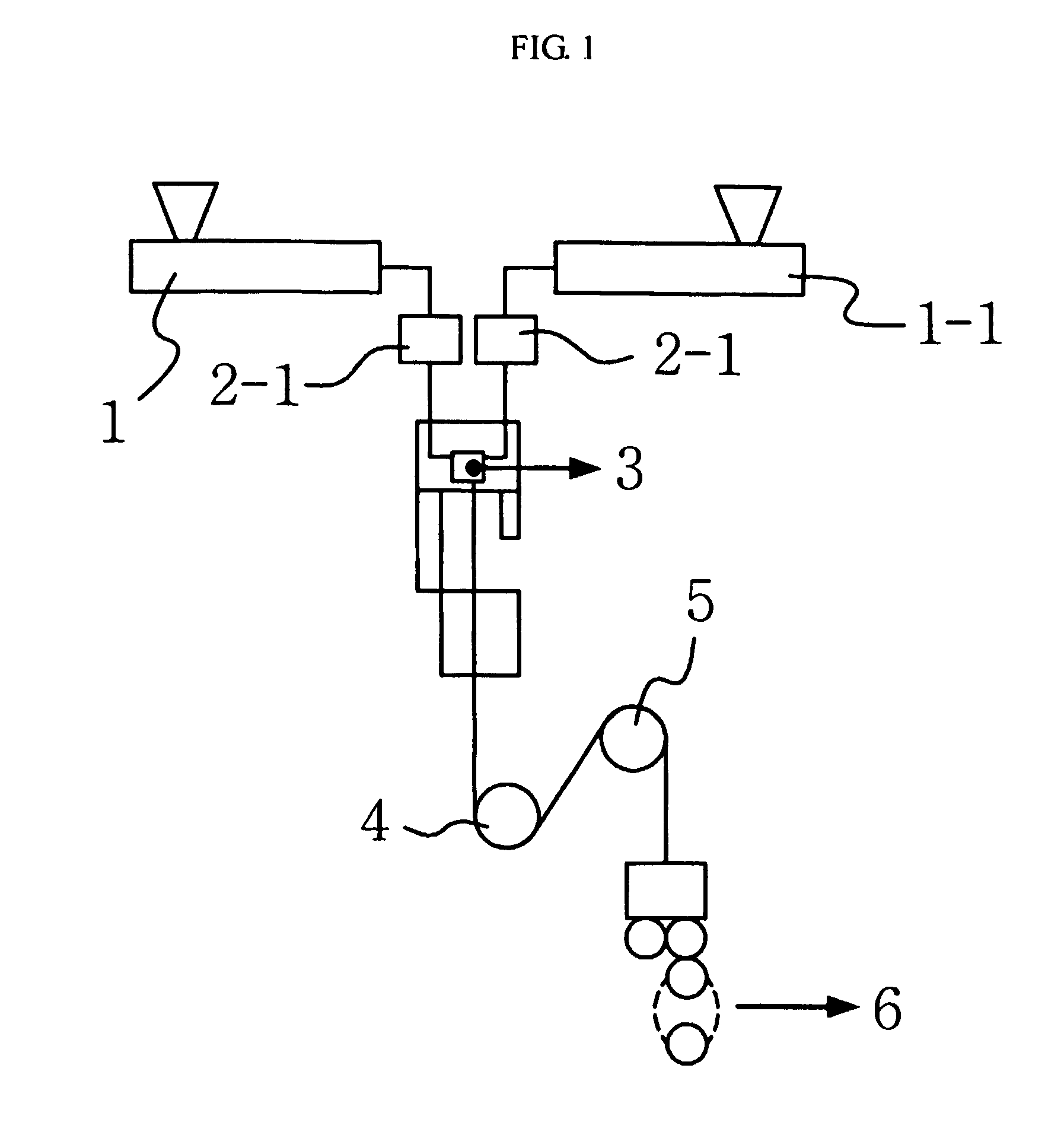

[0050] An inclined circular spinnerette was used for a side-by-side type bi-component spinning process of PET and PTT with a maximized difference of intrinsic viscosity. As a polymer A, PET having intrinsic viscosity of 0.460, 0.550 and 0.635 was used, and PTT having intrinsic viscosity of 1.00 was used as a polymer B, as shown in Table 1, below. Further, under spinning temperature conditions at 270-290° C. and different throughput ratios as in Table 1, below, a conjugated yarn was manufactured through a one-staged process by use of the inclined circular spinnerette. A cooling air of 23° C. at 5-120 cm directly under the nozzle was fed at 0.35 m / sec, and 0.5-1.1 wt % of a spinning oil was used. The resultant yarn was woven in warp and well directions to manufacture a woven fabric of 100 g / m2, which was then dyed at 120° C.

TABLE 1SpinningVisco.Ex.PolymerPolymerTemp.Differ.throughputInterfaceShapeNo.AB(° C.)(poise)RatioratioratioProcess1PET 0.635PTT 1.0029017005:50.201.03One-staged2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt viscosity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com